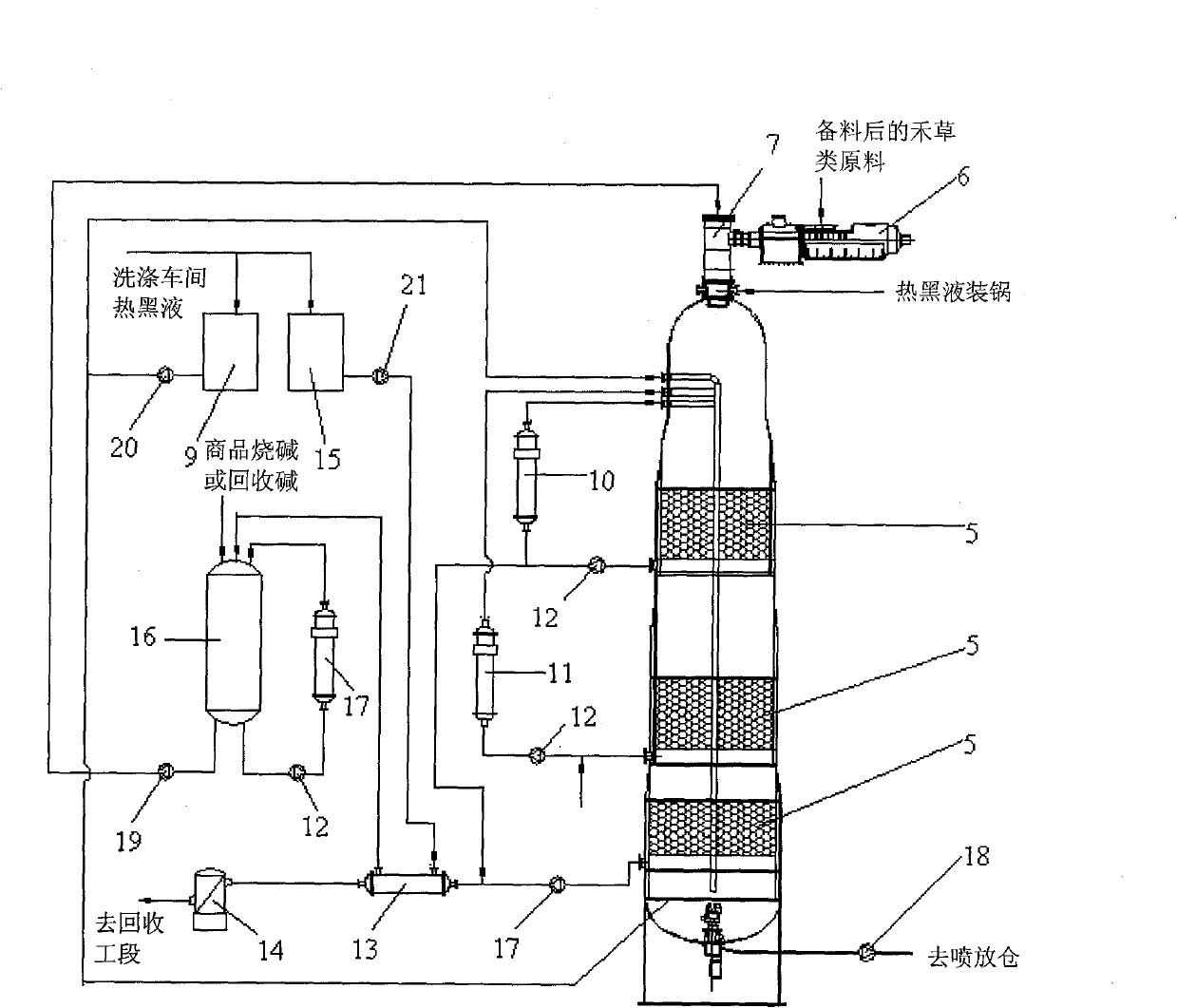

Method for continuously cooking grass raw materials and equipment used in same

A technology for cooking equipment and grasses, which is applied in the field of pulp and paper making, can solve the problems of removal, consumption of cooking liquid, and great environmental harm, and achieve the effects of reducing fiber damage, reducing energy consumption, and improving alkali recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Wheat straw is selected as the raw material and prepared by dry method. It is cut, flattened and kneaded into flakes and filaments in a hammer mill. After winnowing, screening and dust removal, the length of wheat straw flakes is about 20mm at this time. , The impurity removal rate reaches 30%.

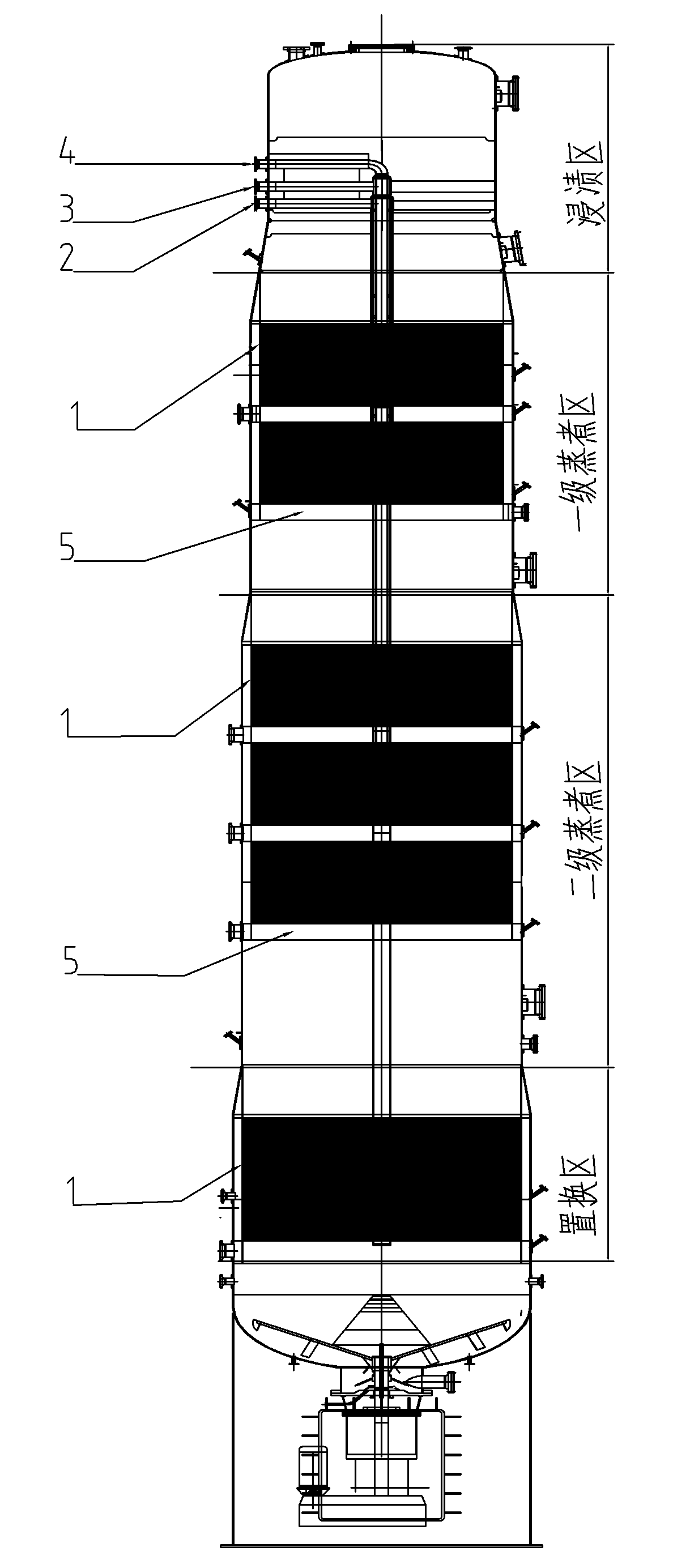

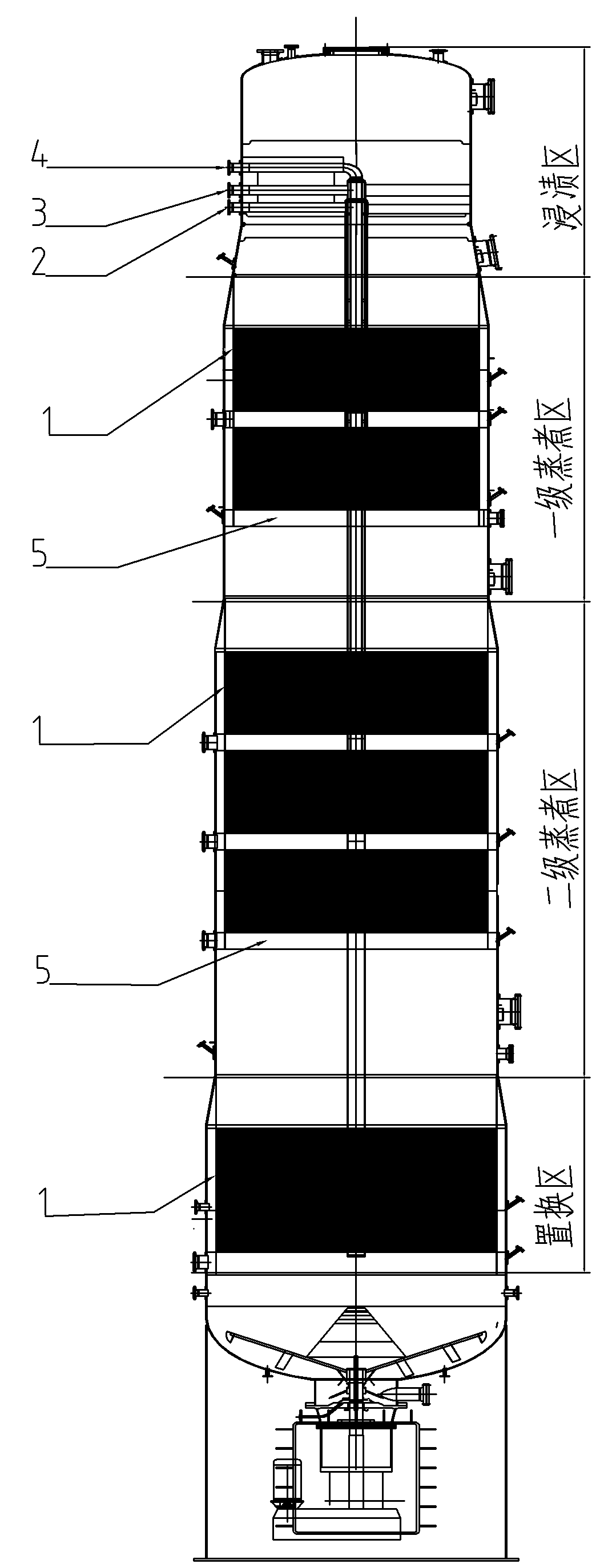

[0113] Then the metered wheat straw is extruded by a screw feeder to form a plug. When the plug enters the T-shaped pipe, the plug of wheat straw expands rapidly and is quickly inhaled and mixed evenly with the addition of impregnating liquid. The impregnating liquid is composed of black liquor and caustic soda Composition: alkali amount for cooking: 18%, anthraquinone: 0.06%, temperature 130°C, liquid ratio controlled at 1:4.5, black liquor solids concentration 13%, impregnating liquid temperature 110°C.

[0114] Put the wheat straw mixed with the soaking liquid and the hot black liquor into the dipping area in the vertical continuous cooking pot through the pot loader, carry ...

Embodiment 2

[0120]Remove the moldy and rotten part of the straw raw material from the forage, and the length is 500-800mm. The straw raw material enters from the entrance of the new-type grass preparation machine with a feeding speed of 0.6m / s through a belt conveyor. The rotating speed of the new-style grass preparation machine is 740rpm, after the raw material is processed, the straw raw material with a length of 30-50mm is discharged at the outlet. Enter the cyclone dust collector system for dust removal treatment, and the straw raw material enters the cylindrical sieve for screening, and the impurity removal rate of dry material preparation by this method reaches 33%.

[0121] The straw raw material after preparation enters the T-shaped pipe through the extruder, and adds impregnating liquid. The impregnating liquid is composed of black liquor and caustic soda liquor. The alkali concentration is 28 grams per liter. (Baume), the solid concentration is 14.0%, and the liquid ratio is con...

Embodiment 3

[0127] Reed is selected as raw material, prepared by dry method, cut, flattened, kneaded into flakes and filaments in a hammer mill, selected by wind, screened, and dedusted, and the impurity removal rate reaches 28%.

[0128] Then the metered reed is extruded by a screw feeder to form a plug. When the plug enters the T-shaped pipe, the plug of the reed expands rapidly and is quickly inhaled and mixed evenly by adding the impregnating liquid. The impregnating liquid is composed of black liquor, caustic soda, Sodium sulfide is composed of 10% alkali, 8% sulfide, 120°C temperature, 1:4.5 liquid ratio, and 14% black liquor solids concentration.

[0129] The reeds mixed with the soaking liquid and the hot black liquor are put into the dipping area in the vertical continuous cooking pot through the pot loader, and the liquid ratio is controlled. At this time, the liquid ratio is 1:9, and it starts to enter the first stage after 15 minutes of dipping treatment. In the cooking area, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear | aaaaa | aaaaa |

| Tear | aaaaa | aaaaa |

| Tear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com