Array optical tweezers based on multicore polarization-preserving fiber and manufacturing method thereof

A polarization-maintaining optical fiber and multi-core optical fiber technology, applied in the field of optical fiber technology research, can solve the rare problems of single-fiber optical tweezers and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

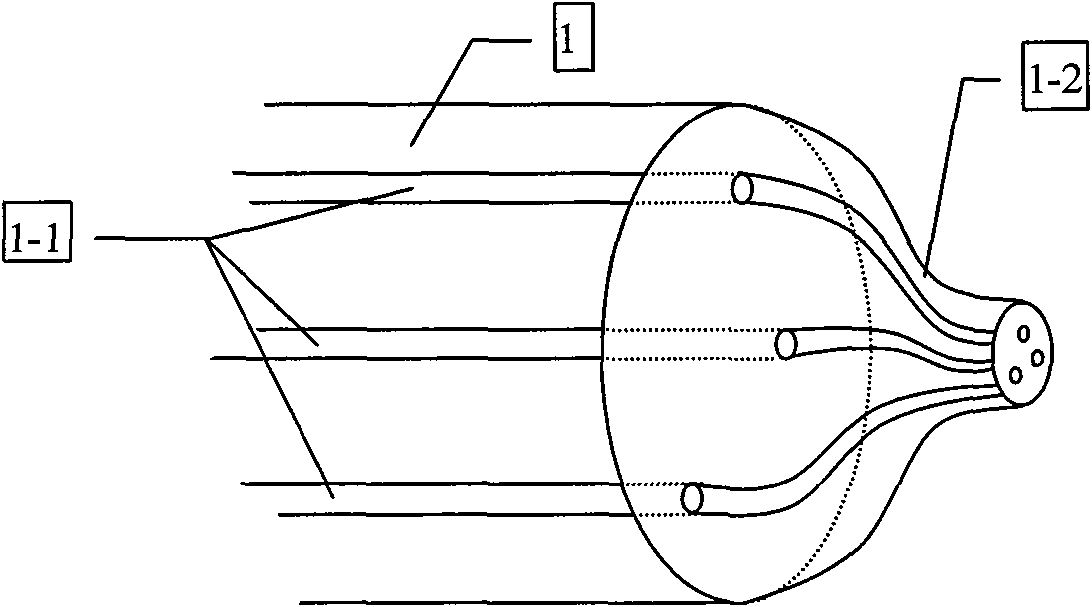

[0021] figure 1 Schematic diagram of the multi-core fiber array optical tweezers system. In the figure, a dual-core polarization-maintaining fiber is taken as an example to show a schematic diagram of the system structure of the array fiber optical tweezers. In the figure, 1 is the multi-core optical fiber, 1-1 is the core of the multi-core optical fiber, 1-2 is the tip structure of the vertebral platform prepared by thermal fusion drawing and cutting, 2 is the standard single-mode optical fiber, 3 is the laser light source, 4 It is the coupling connection between the multi-core optical fiber 1 and the standard single-mode optical fiber 2.

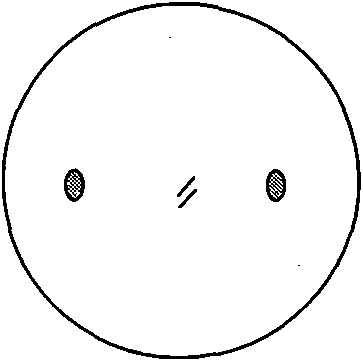

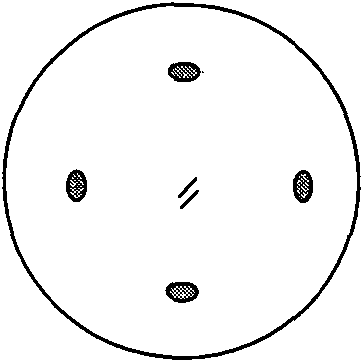

[0022] Fig. 2 Schematic cross-sectional view of multi-core microstructured optical fiber. The left side of the figure is a dual-core fiber, the middle is a three-core fiber, and the right side is a four-core fiber. The shad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com