Method for producing aluminum titanate ceramic

A technology of aluminum titanate and ceramics, applied in the field of dry preparation of aluminum titanate ceramics, can solve the problem of taking a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In the production method of the present invention, such titanium dioxide source powder and alumina source powder are used as raw material powders. These raw material powders are mixed and dry pulverized to obtain a premix. Alternatively, a titanium dioxide source powder, an alumina source powder, and a magnesia source powder may be mixed together and dry pulverized to obtain a premix.

[0029] As a magnesium oxide source powder, the powder of magnesium oxide (magnesia) is mentioned, for example.

[0030] The magnesia source powder may also contain a compound capable of forming magnesia by sintering alone in air. Examples of such compounds include magnesium salts, magnesium alkoxides, magnesium hydroxide, magnesium nitride, and metallic magnesium.

[0031] Specific examples of magnesium salts include magnesium chloride, magnesium perchlorate, magnesium phosphate, magnesium pyrophosphate, magnesium oxalate, magnesium nitrate, magnesium carbonate, magnesium acetate, magn...

Embodiment 1

[0075] 19.6 g of titanium oxide powder [DuPont, "R-900"], 27.0 g of α-alumina powder [Sumitomo Chemical Co., Ltd., "AES-12"], 1.6 g of magnesium carbonate powder [Kamishima Chemical ( Co., Ltd., "Jinxing"] and 1.8g of powdered feldspar [large flat feldspar obtained from Special Concentrate Co., Ltd., model SS-300], and 5kg of alumina beads [diameter 15mm] were put into the alumina production line Crushing container [inner volume 3.3L]. The total volume of the mixture of titanium oxide powder, alpha alumina powder and feldspar is about 50 cm 3 . Afterwards, using a vibrating mill, the crushing container was vibrated for 2 minutes under the conditions of amplitude 5.4mm, vibration frequency 1760 times / min [equivalent to acceleration 10G], and power 5.4kW, thereby pulverizing the mixture in the crushing container to obtain a premix . 5 g of this pre-mixture was put into an alumina crucible, and the temperature was raised to 1450° C. at a heating rate of 300° C. / hour in an elec...

Embodiment 2

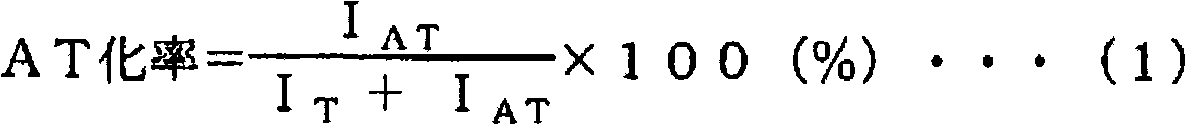

[0079] In addition to the use of titanium oxide powder [R-900] of 23.0g, α-alumina powder [AES-12] of 19.6g, magnesium carbonate powder [Venus] of 4.0g, feldspar [SS- 300] was used in an amount of 3.3g, and all the others were operated in the same manner as in Example 1 to obtain a sintered product and powder. The obtained powder showed an X-ray diffraction peak of aluminum magnesium titanate, and its AT rate was 100%. In addition, in this powder, almost all the particles constituting the powder are as large as spherical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com