Method for preparing spherical porous silver powder

A porous silver and spherical technology is applied in the field of preparation of spherical porous silver powder, which can solve the problems of high energy consumption and waste liquid generation, and achieve the effects of low cost, no pollution and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Ag / Mg alloy was prepared according to Ag20% (wt) Mg. A vacuum melting method is used to prepare the master alloy. When melting and atomizing under the protection of argon, 3% of metallic magnesium is added to control the atomization temperature to 970°C.

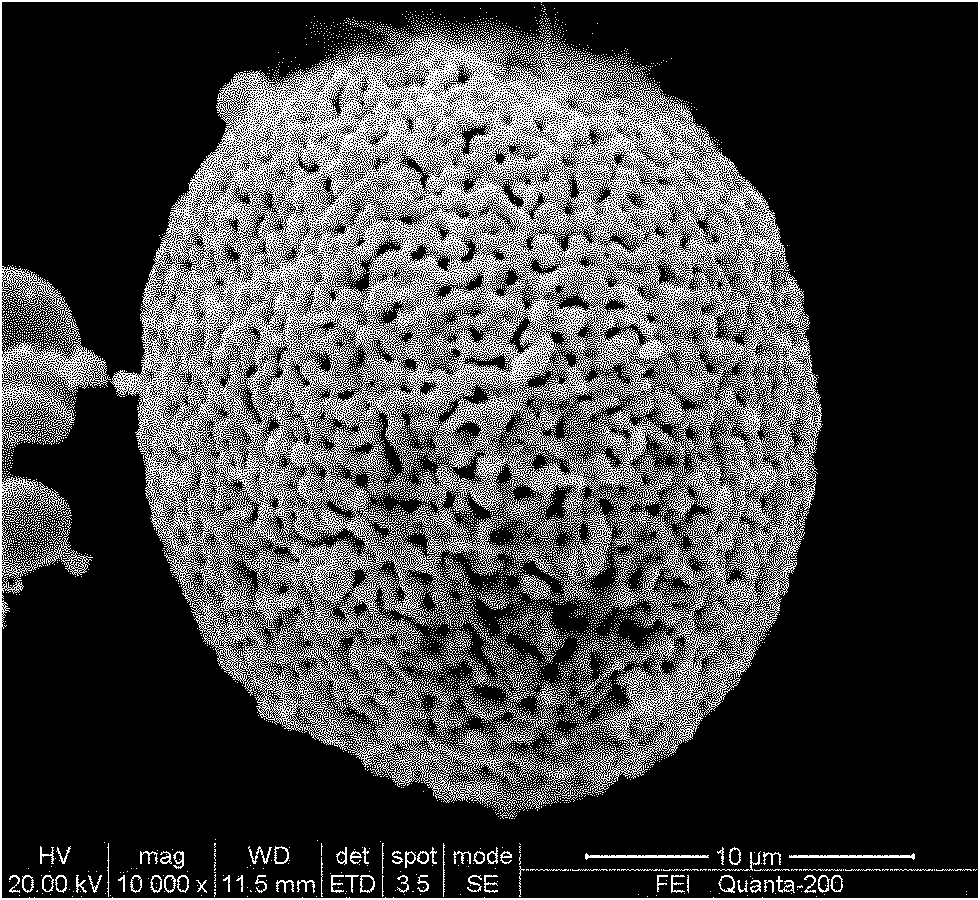

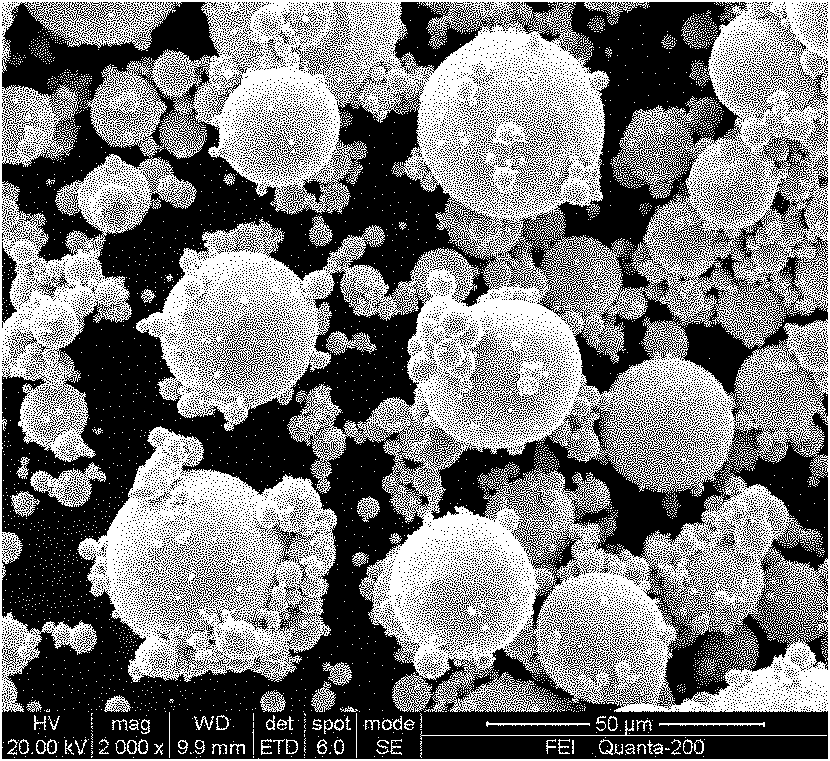

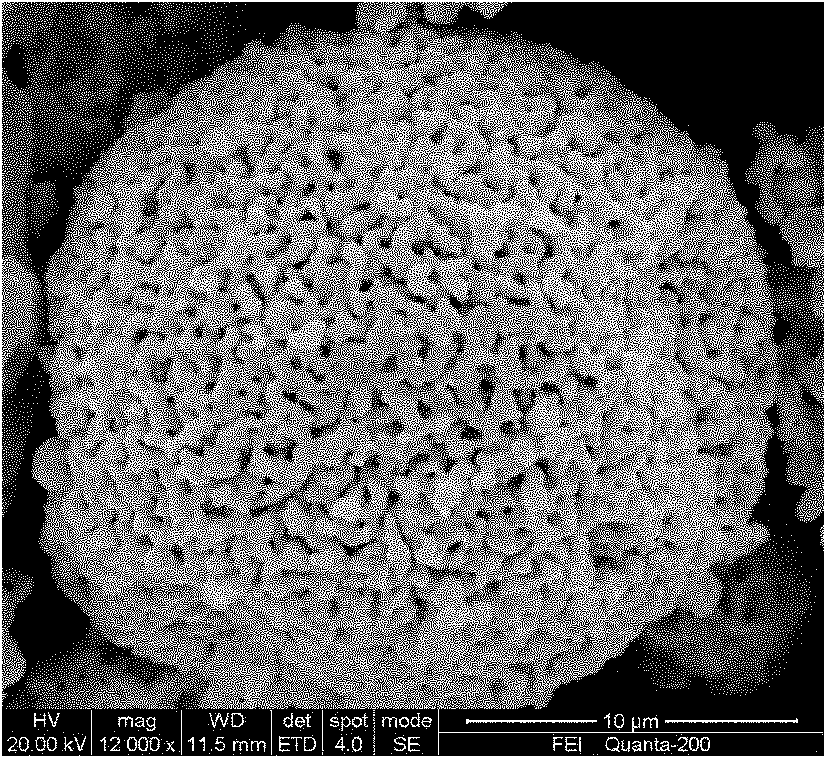

[0038] Using nitrogen as the atomizing medium, control the atomizing pressure to 0.8MPa. The obtained metal powder is shown in Figure 2(a). The metal powder is sieved with a 200-mesh sieve, and the average particle size is about 20 microns.

[0039] Using 3.5% sodium chloride aqueous solution as the silver-magnesium alloy powder leaching agent, first leaching at room temperature for 60 to 90 minutes, when the leaching speed slows down significantly, heat the sodium chloride aqueous solution to 50 ℃ and continue leaching for 30 to 60 minutes ; Finally, use a newly prepared sodium chloride aqueous solution at 100°C for 30 to 60 minutes to extract all the magnesium in the silver-magnesium alloy powder to obtain spherical por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com