Method and device for preparing uniform solidified particles by orifice injection

A particle and uniform technology, applied in the field of high melting point microparticles preparation, can solve the problems of unstable precision, difficulty, and no obvious progress in the research of high melting point microparticles preparation, and achieve the effect of simple device, good sphericity and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

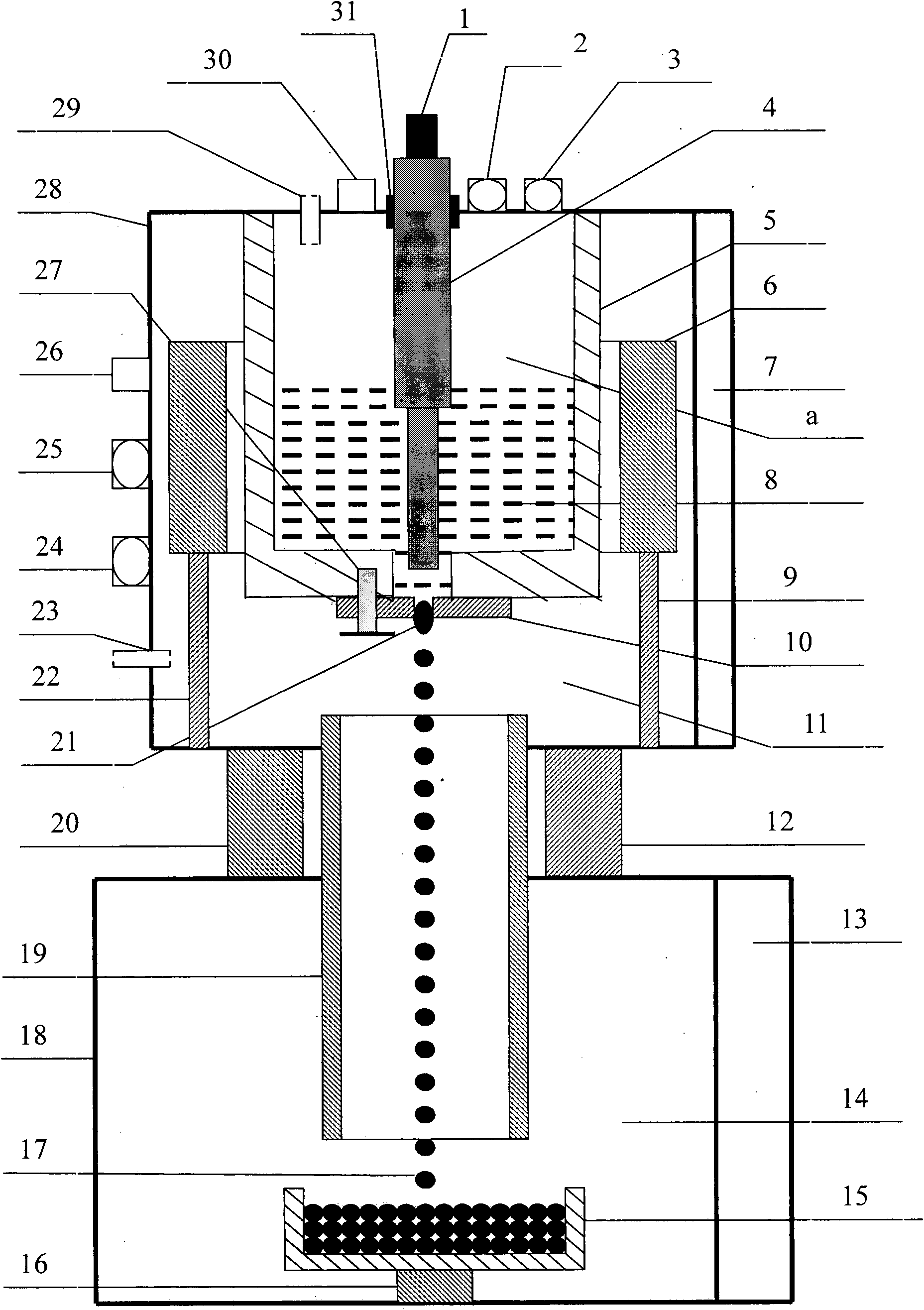

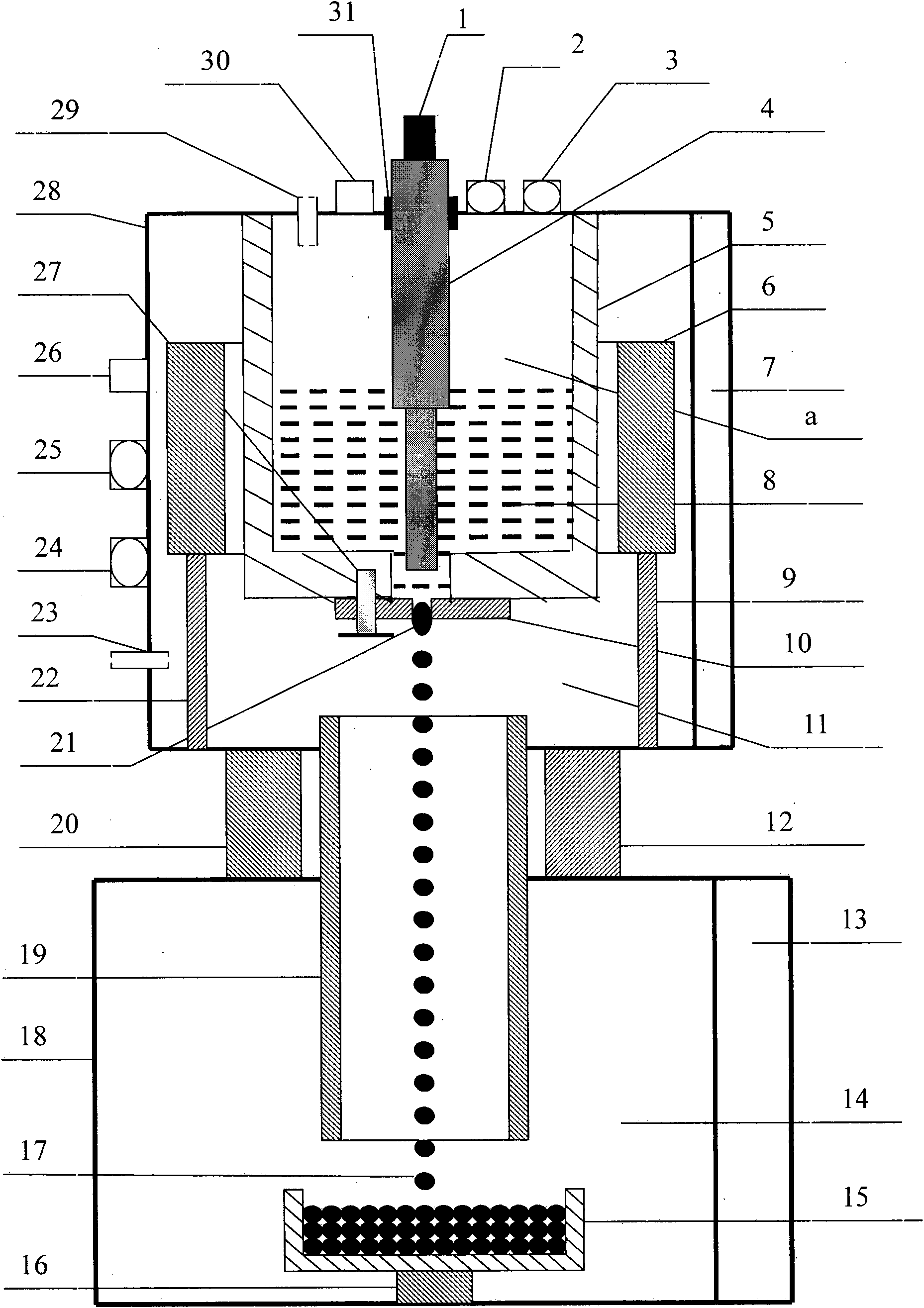

[0016] Example 1 Preparation of uniformly solidified copper particles: First, the copper block was crushed into particles with a size of 2 cm, and the particles were put into a crucible 5 with a center hole, and the amount of the particles was half of the capacity of the crucible 5 with a center hole. Then, install the graphite bolt 10 with spray holes through four evenly distributed screws 27 to the bottom of the crucible 5 with a center hole, and manually adjust the position of the piston rod 4 until the piston rod 4 and the spray hole The distance of the bolt 10 is 2cm, close the furnace door 7; use the mechanical pump 2 to pump the crucible cavity a to a low vacuum of 1Pa, and then use the upper diffusion pump 3 to pump the crucible cavity a to a high vacuum of 0.001Pa; use the side mechanical pump 24 to The furnace body 11 and the warehouse body 14 are pumped to a low vacuum of 1 Pa, and then the side diffusion pump 25 is used to pump the furnace body 11 and the warehouse b...

example 2

[0017] Example 2 Preparation of uniformly solidified silicon particles: First, the silicon block was crushed into 1cm-sized particles, and the particles were loaded into a crucible 5 with a center hole, and the amount of loaded reached half of the capacity of the crucible 5 with a center hole , Then install the quartz bolt 9 with spray holes through four evenly distributed screws 27 to the bottom of the crucible 5 with a center hole, and manually lower the position of the piston rod 4 until the piston rod 4 is in contact with the spray hole The bolt 10 is at a distance of 1 cm, close the furnace door 7; use the upper mechanical pump 2 to pump the crucible cavity a to a low vacuum of 1 Pa, and then use the upper diffusion pump 3 to pump the crucible cavity a to a high vacuum of 0.001 Pa; use the side mechanical pump 24 to pump the furnace The body 11 and the chamber body 14 are pumped to a low vacuum of 1 Pa, and the side diffusion pump 25 is used to pump the furnace body 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com