Graphite material for producing nanogate carbon and preparation method thereof

A graphite material and nano-carbon technology, applied in the field of graphite materials, can solve the problem that the bulk density, purity and resistivity cannot meet the requirements of use, the performance and scale cannot meet the market demand at the same time, and the production technology of isostatic graphite products is immature, etc. problems, to achieve the effect of shortening the production cycle, speeding up the excitation speed, improving the bulk density and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

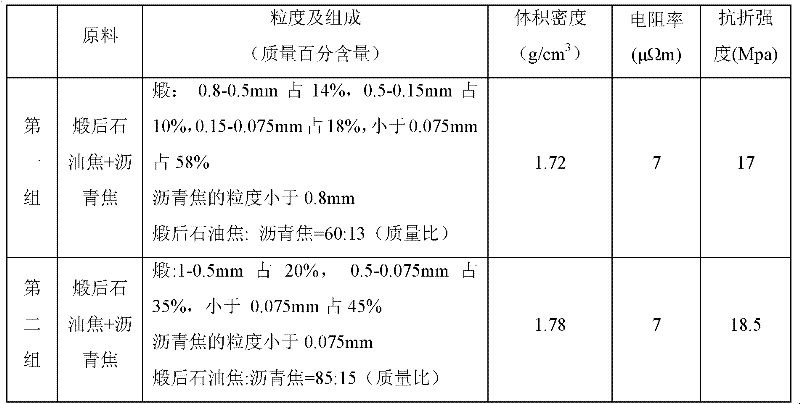

[0046] After the calcined petroleum coke is crushed and sieved, it is made into three grades of pellets of 1-0.5mm, 0.5-0.075mm and powder (particle size less than 0.075mm), which are placed in three silos respectively; pitch coke After being crushed and sieved, it is made into powder, stored in the silo, and then the calcined petroleum coke and pitch coke are proportioned (85:15) through electronic batching; the calcined petroleum coke is divided into 1 -0.5mm accounts for 20%, 0.5-0.075mm accounts for 35%, and powder accounts for 45% for proportioning.

[0047] Put the above-mentioned mixture into a kneading pot for dry mixing, the dry mixing time is 20 minutes, and the temperature of the dry material is 120°C.

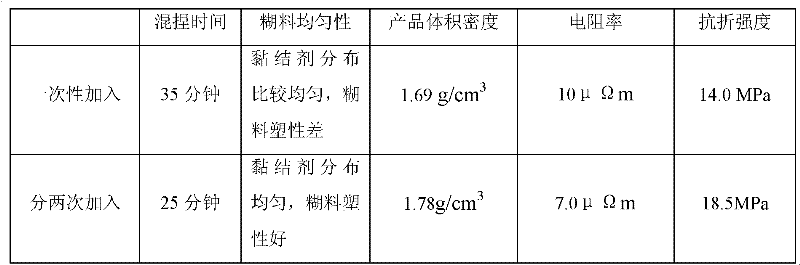

[0048] Add modified asphalt to the kneading pot for wet mixing, the mass percentage of dry material and modified asphalt is 75:25, wherein the modified asphalt is added in two times, the first addition is 45% of the total modified asphalt, Kneading with the dry mat...

Embodiment 2

[0055] After the calcined petroleum coke is crushed and sieved, it is made into three grades of pellets of 1-0.5mm, 0.5-0.075mm and powder (particle size less than 0.075mm), which are placed in three silos respectively; pitch coke After being crushed and sieved, it is made into powder, stored in the silo, and then the calcined petroleum coke and pitch coke are proportioned (90:10) through electronic batching; the calcined petroleum coke is divided into 1 -0.5mm accounts for 25%, 0.5-0.075mm accounts for 35%, and powder accounts for 40% for proportioning.

[0056] Put the above mixed materials into a kneading pot for dry mixing, the dry mixing time is 30 minutes, and the temperature of the dry materials is 130°C.

[0057] Add modified asphalt to the kneading pot for wet mixing, the mass percentage of dry material and modified asphalt is 80:20, wherein the modified asphalt is added in two times, the first addition is 50% of the total modified asphalt, Kneading with the dry mate...

Embodiment 3

[0064] After the calcined petroleum coke is crushed and sieved, it is made into three grades of pellets of 1-0.5mm, 0.5-0.075mm and powder (particle size less than 0.075mm), which are placed in three silos respectively; pitch coke After crushing and screening, it is made into powder, stored in the silo, and then the calcined petroleum coke and pitch coke are mixed according to (88:12) through electronic batching; the calcined petroleum coke is divided into 1 -0.5mm accounts for 25%, 0.5-0.075mm accounts for 30%, and powder accounts for 45% for proportioning.

[0065] Put the above mixed materials into a kneading pot for dry mixing, the dry mixing time is 25 minutes, and the temperature of the dry materials is 125°C.

[0066] Add modified asphalt to the kneading pot for wet mixing, the mass percentage of dry material and modified asphalt is 77:23, wherein the modified asphalt is added in two times, the first addition is 55% of the total modified asphalt, Kneading with the dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com