Circulating pump sealing oil and application thereof

A sealing oil and circulating pump technology, which is applied in the petroleum industry, base materials, lubricating compositions, etc., can solve the problems that the physical properties of oil products cannot meet the requirements of sealing oil, high process cost, and expensive price, etc., and achieve low processing cost and reduced The effect of high production cost and high use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Another aspect of the present invention relates to the preparation method of above-mentioned sealing oil, comprising:

[0056] S1) Hydrotreating the base oil raw material to obtain a hydrogenated base oil; optionally performing hydrotreating on the low-density blend oil;

[0057] S2) Fractionally distilling the low-density blend oil and the hydrogenated base oil to remove light components and moisture, and obtain seal oil containing the hydrogenated base oil and the low-density blend oil;

[0058] Wherein, the base oil raw material is selected from at least one of coal liquefaction solvent oil, heavy aromatic oil, and anthracene oil.

[0059] Preferably, S1) is hydrogenated by one of the following methods:

[0060] Method 1: mixing a) base oil raw material with b) low-density blended oil, and then performing hydrotreating on the mixture of a) base oil raw material and b) low-density blended oil; or

[0061] Mode 2: Hydrotreating a) the base oil raw material, and then ...

Embodiment 1

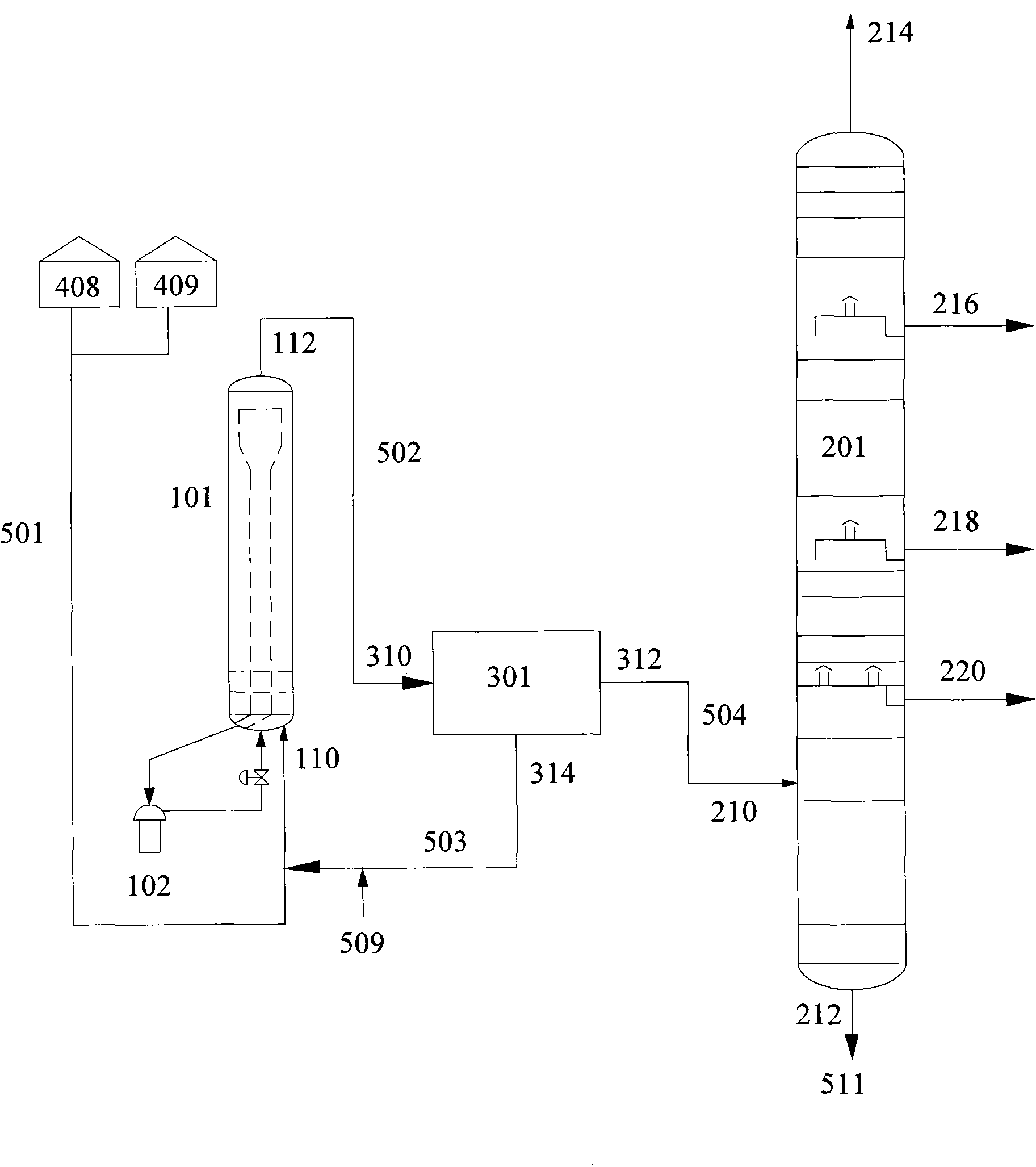

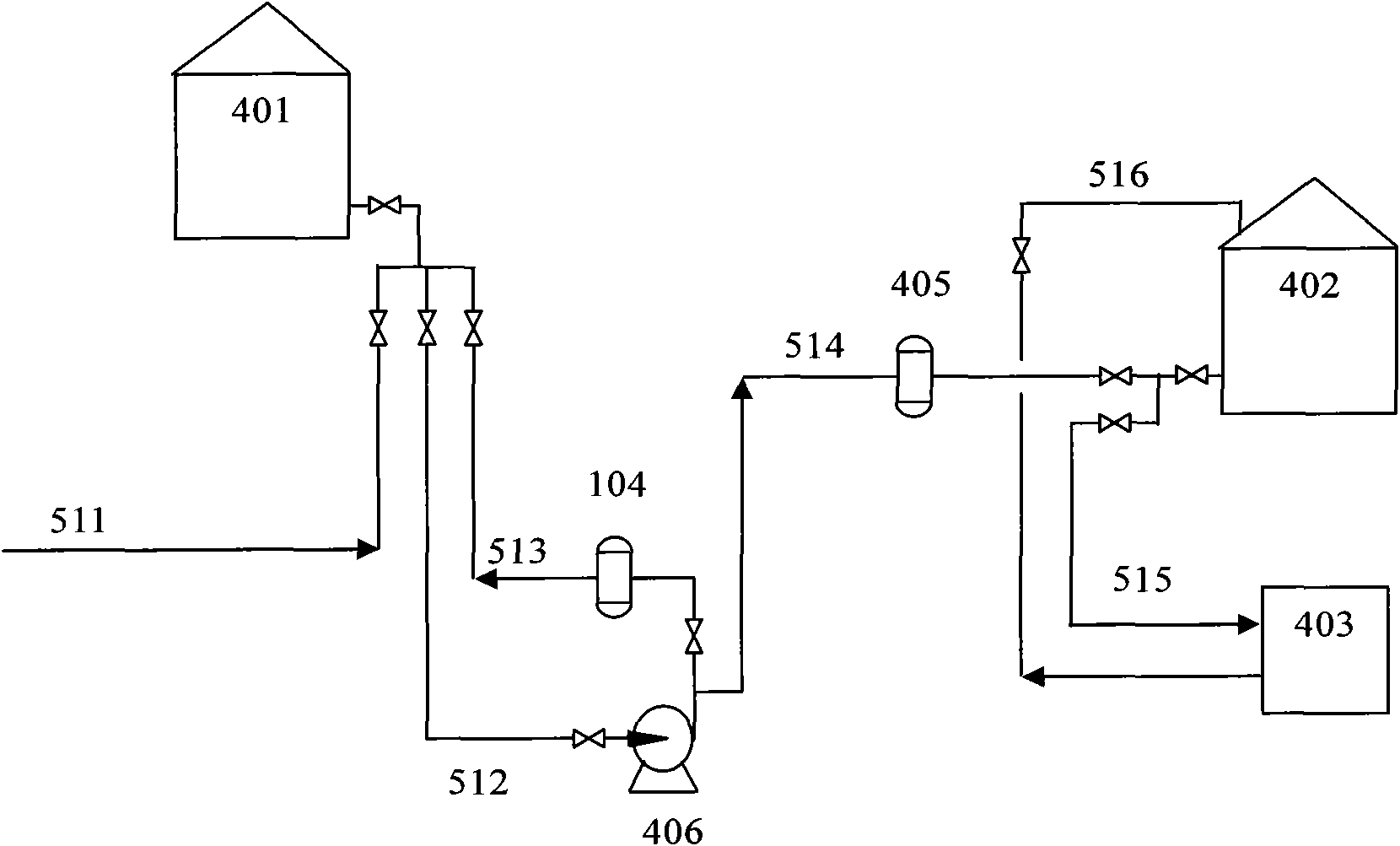

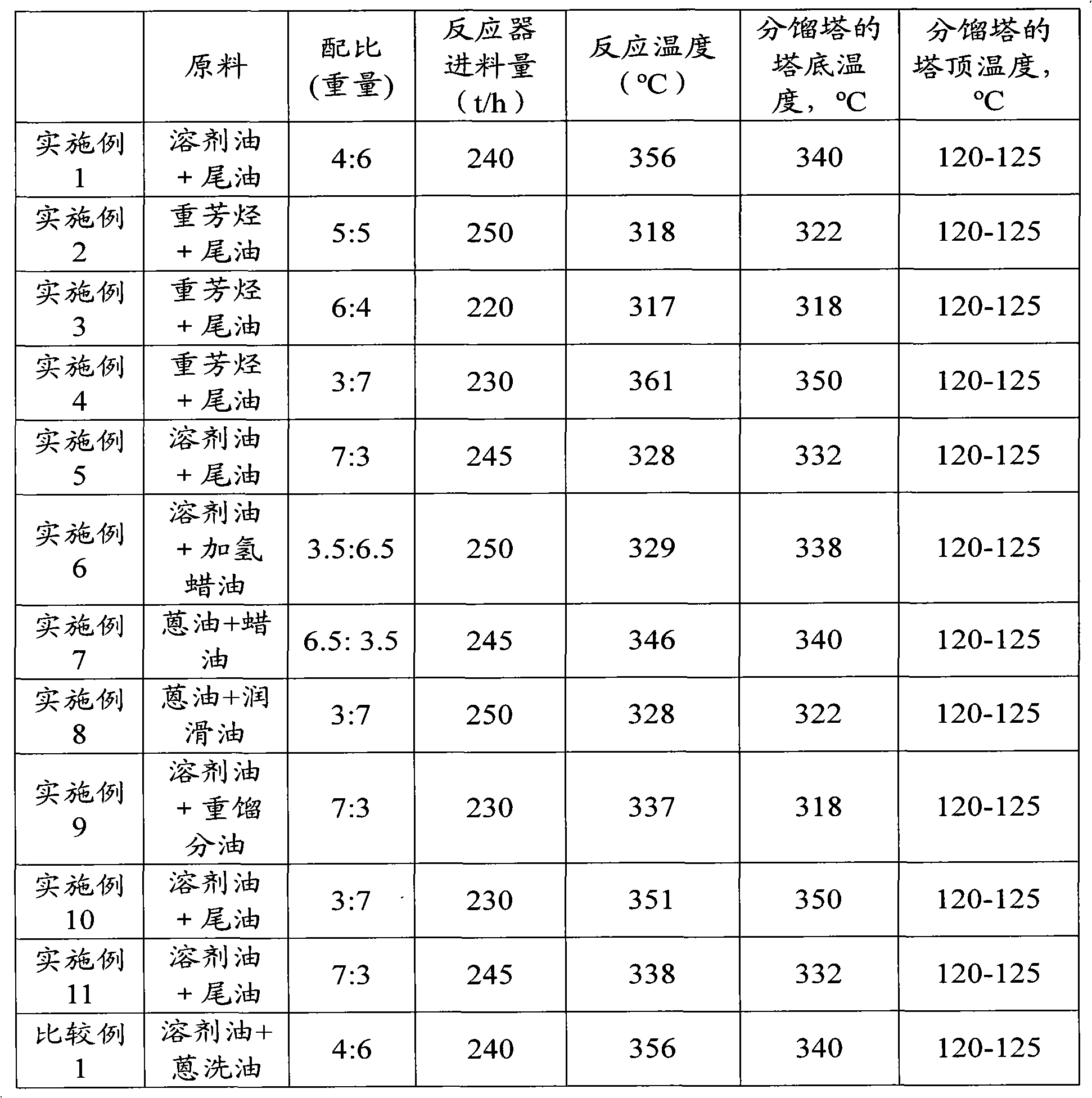

[0110] use figure 1 with figure 2 process shown. Tail oil and coal liquefied solvent naphtha are fed into the reactor at a ratio of 1:1. The fresh feed rate is 150t / h, the system feed rate is 240t / h, and the hydrogen consumption is 17000Nm 3 / h. The system pressure was kept at 13.00MPa, the reactor inlet temperature was kept stable at 318-320°C, and the reactor bed temperature was kept at 356°C. In the fractionation system, the reaction temperature began to drop after the tail oil entered the system, so the temperature of the hot feed for fractionation dropped and remained at 356°C; the cold feed was maintained at 213°C; the pressure at the top of the tower was maintained at 0.15MPa; the amount of stripping steam was maintained at 4.6 t / h; tower top temperature: 120-125°C; the extraction temperatures of each side line are: side line two: 216 °C, side line three: 283 °C, tower bottom: 340 °C. bottom fraction by figure 2 Filtration is performed in the process shown to fu...

Embodiment 2

[0112] The fresh feed is raised to 160t / h, the ratio is 1:1 heavy aromatics in the tail oil, and the system feed is 250t / h. Due to the change of raw material properties, the reaction temperature was lowered to 318°C, and the reactor inlet temperature was raised slightly to 302°C. Hydrogen consumption dropped to 10000Nm 3 / h. Slowly reduce the fresh feed to 80t / h. In the fractionation system, since the reaction temperature began to drop, the fractionation hot feed temperature dropped to maintain at 328°C, and the cold feed was maintained at 205°C. The pressure at the top of the tower is maintained at 0.15Mpa. The stripping steam volume is maintained at 4.6t / h. Tower top temperature: 120-125°C. The extraction temperature of each side line: the second line on the side: 177°C, the third line on the side: 230°C, the bottom of the tower: 322°C. bottom fraction by figure 2 Filtration is performed in the process shown to further remove mechanical impurities and moisture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com