Oversized high-strength heatproof magnesium alloy ingot blank semicontinuous casting technique

A technology of super-large size and casting process, which is applied in the field of magnesium alloy casting, and can solve problems such as increased shrinkage, increased casting thermal stress, and difficulty in casting ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

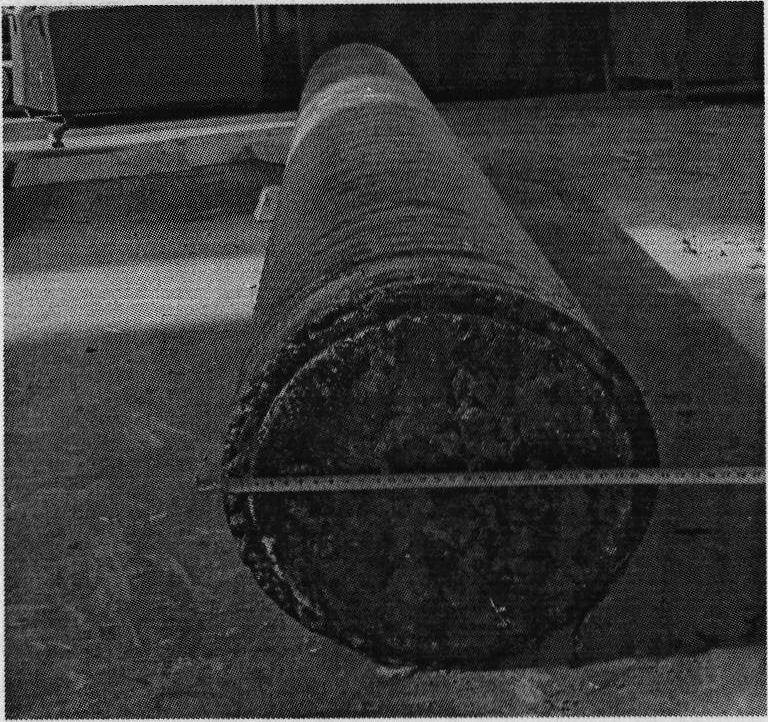

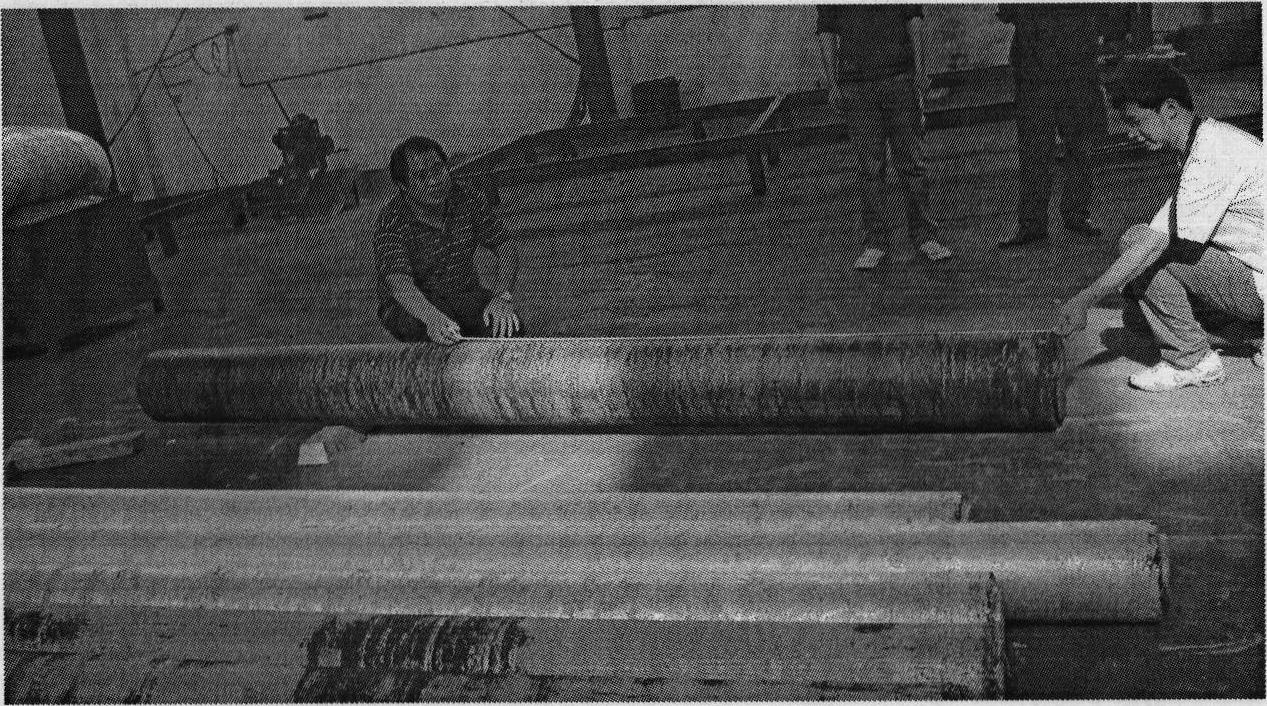

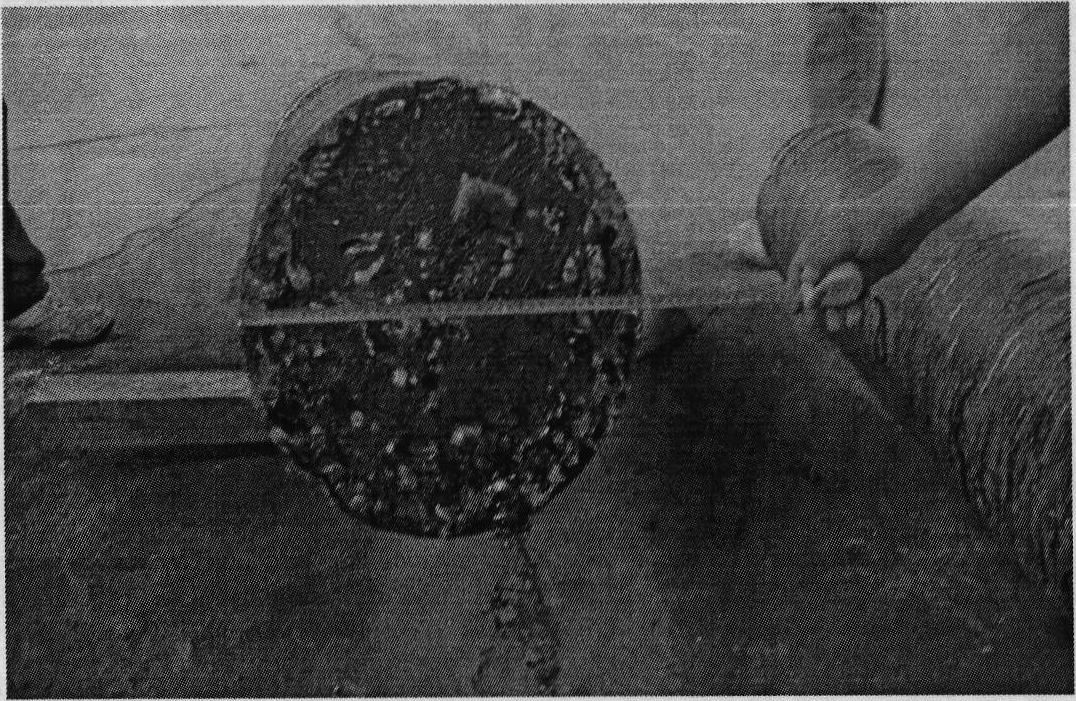

Image

Examples

Embodiment 1

[0022] In this embodiment, various process parameters of semi-continuous casting are adjusted to obtain high-quality super-large-sized high-strength magnesium alloy ingots. After the magnesium alloy melt is refined and left to stand, the low-pressure transfer technology and flow control technology of the melt are used to realize the micro-controllable flow of the alloy liquid during the pouring process. The specific process steps are as follows:

[0023] a. Melting magnesium, melting the high-purity magnesium ingot in an iron crucible, the melting temperature is 720°C, and adding 5# flux at the same time;

[0024] b. When the magnesium ingot is completely melted, add Mg-Gd, Mg-Y, and Mg-Zr master alloys in sequence, the temperature is 790°C, and sprinkle 5# flux in an appropriate amount to protect the melt;

[0025] c. When the alloy is completely melted, stir, and remove slag after degassing with argon;

[0026] d. The temperature drops to 700°C, and the temperature is kept...

Embodiment 2

[0029] In this embodiment, various process parameters of semi-continuous casting are adjusted to obtain high-quality super-large-sized high-strength magnesium alloy ingots. After the magnesium alloy melt is refined and left to stand, the low-pressure transfer technology and flow control technology of the melt are used to realize the micro-controllable flow of the alloy liquid during the pouring process. The specific process steps are as follows:

[0030] a. Melting magnesium, melting the high-purity magnesium ingot in an iron crucible, the melting temperature is 720°C, and adding 5# flux at the same time;

[0031] b. When the magnesium ingot is completely melted, add Mg-Gd, Mg-Y, and Mg-Zr master alloys in sequence, the temperature is 790°C, and sprinkle 5# flux in an appropriate amount to protect the melt;

[0032] c. When the alloy is completely melted, stir, and remove slag after degassing with argon;

[0033] d. The temperature is lowered to 700 ° C, and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com