Combustion motor and stirling compound engine

A technology of Stirling engine and internal combustion engine, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of low energy utilization rate, no power output of waste heat air conditioning technology, and complex system, so as to improve power performance. , compact structure, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

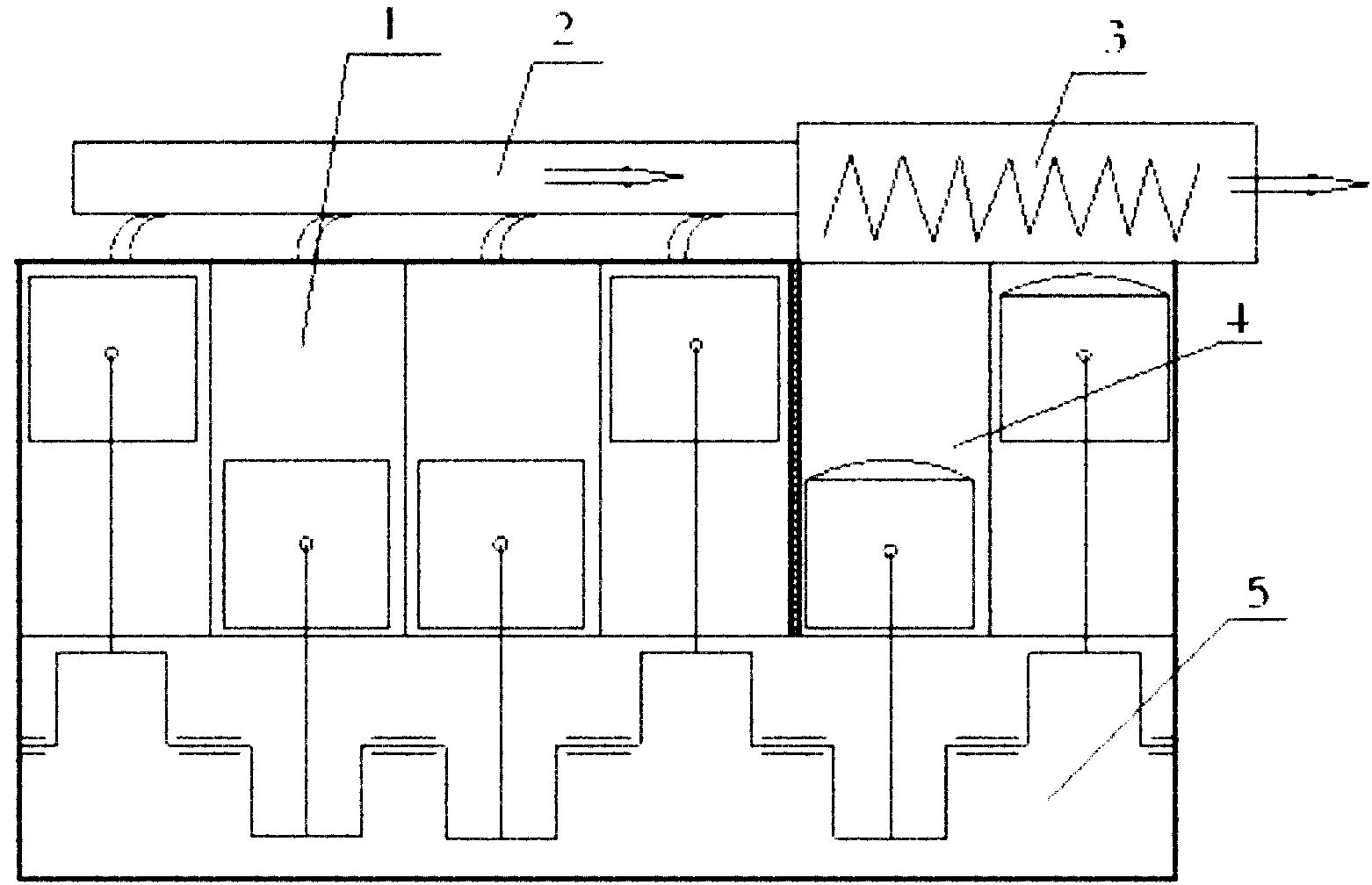

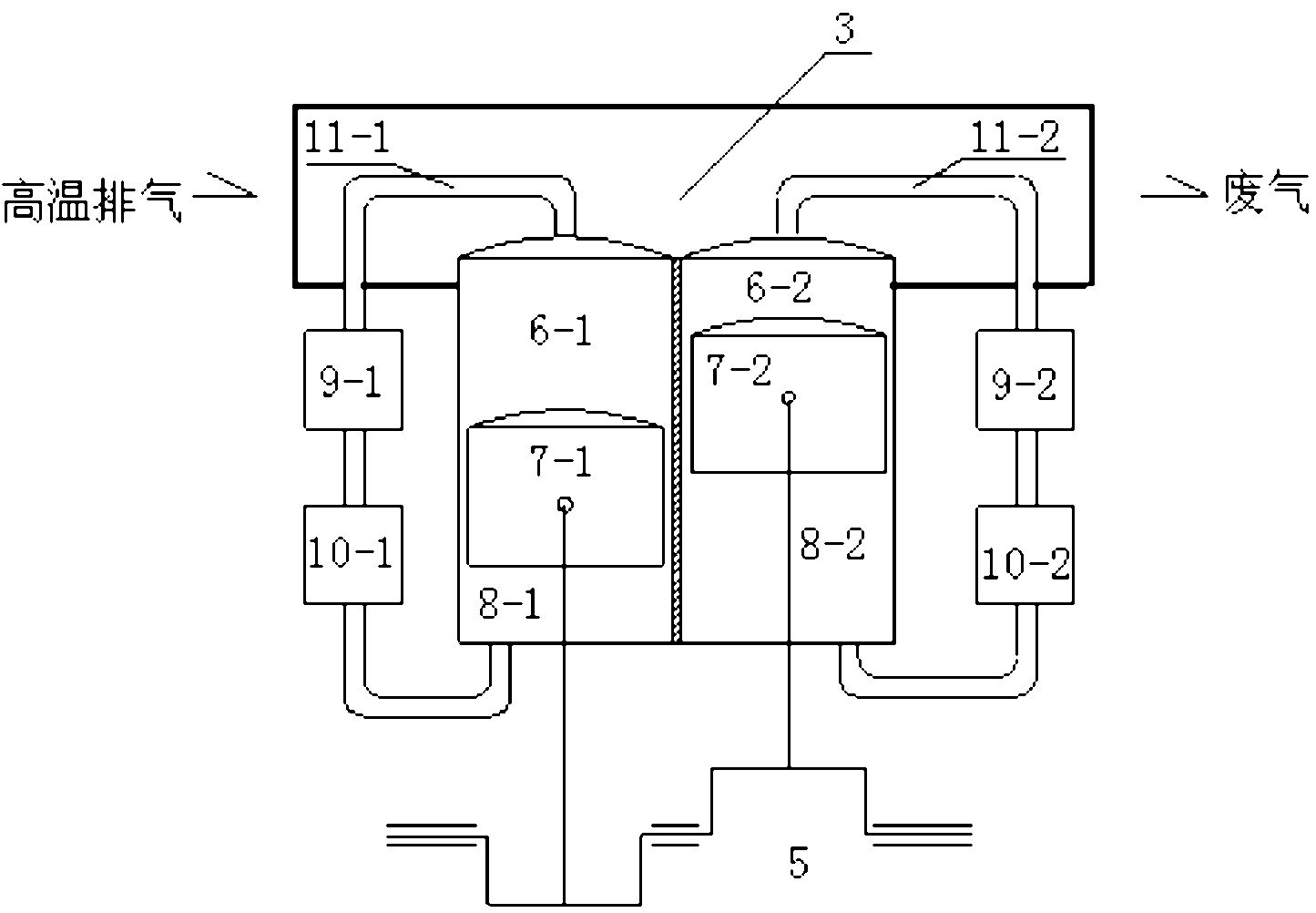

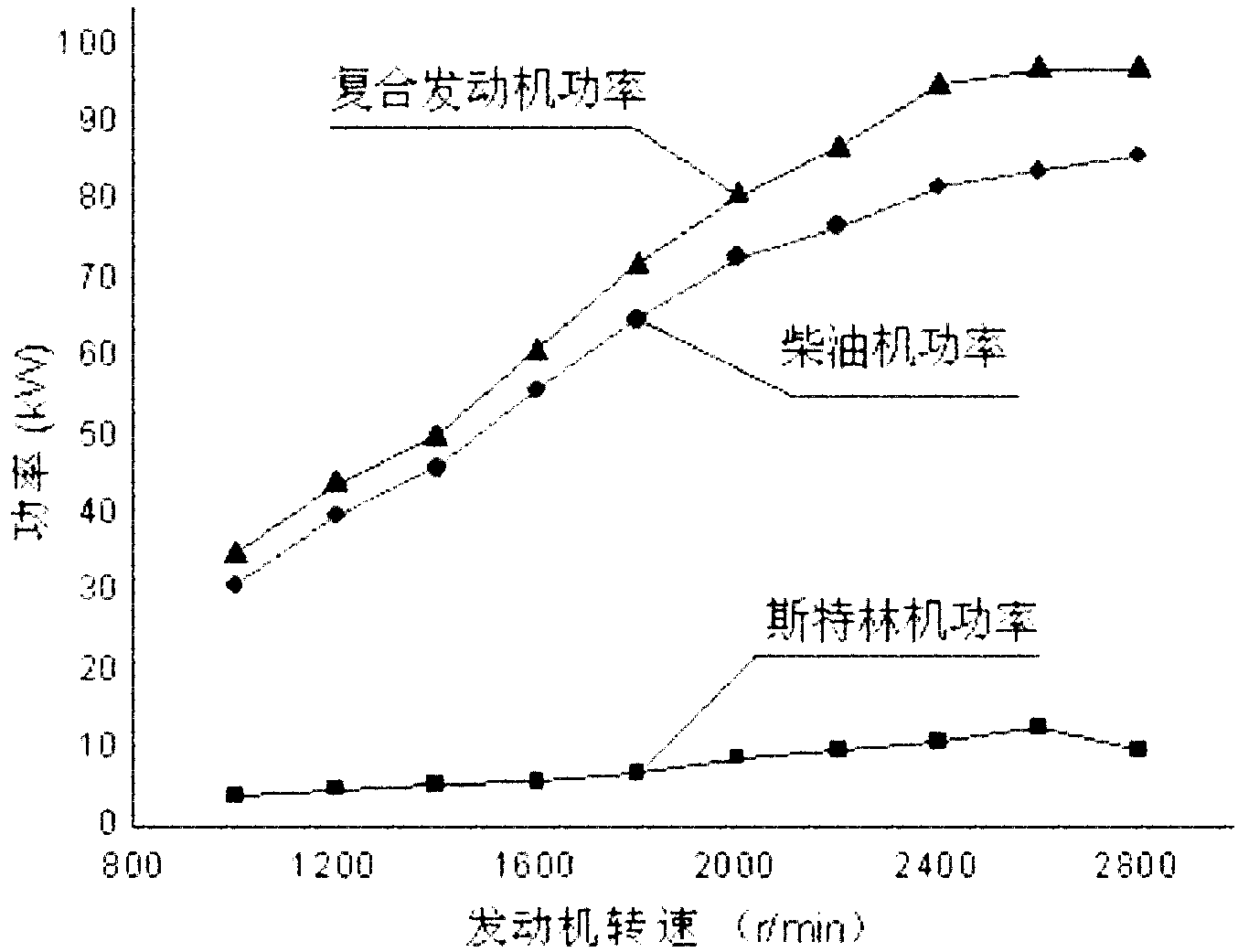

[0010] The present invention will be further described below in conjunction with accompanying drawings and examples. Structurally, the internal combustion engine 1 and the Stirling engine 4 are combined into one body, the exhaust pipeline 2 of the internal combustion engine 1 is connected in series with the heater 3 of the Stirling engine, and the exhaust gas of the internal combustion engine is used as a high-temperature heat source of the Stirling engine 4, The same crankshaft 5 is driven by the power generated by the two systems of internal combustion engine 1 and Stirling engine 4 (such as figure 1 ). After the high-temperature exhaust gas is transferred to the working medium of the Stirling engine through the heater, the low-temperature exhaust gas is discharged to the atmosphere. The working fluid in the Stirling engine passes through two identical closed loops (such as figure 2 ), the circulating working medium can be hydrogen or helium. The first circulation loop i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com