Preparation method and use of main ingredient of fragrance releasing agent for tobacco with jasmine fragrance

A technology of jasmine fragrance and release agent, which is used in the application of cigarette flavoring and addition, and the field of preparation of jasmine fragrance flavor release agent for cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

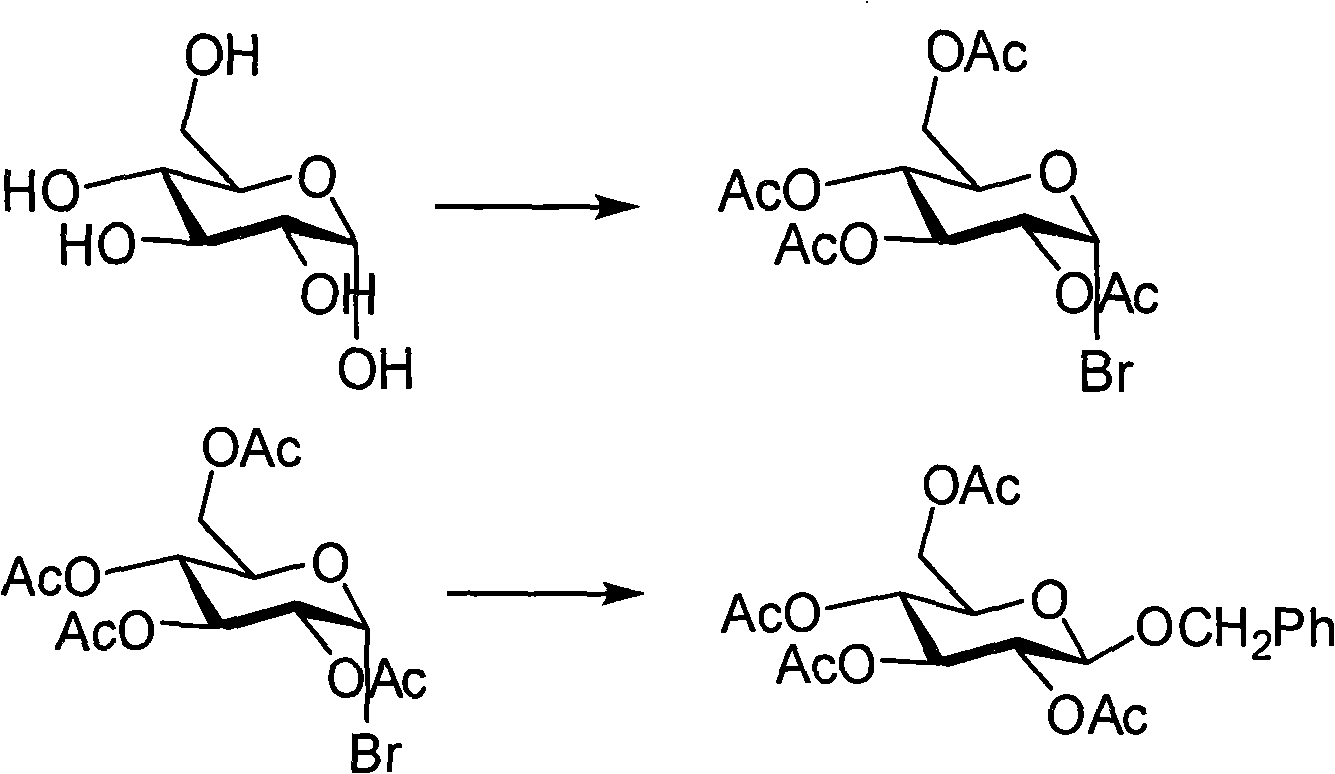

[0018] Example 1: The specific operation process is as follows: a 250mL flask with a stirrer is placed in an ice-water bath, 0.424mol (40mL) acetic anhydride is added, cooled to 4°C, and 0.24mL of 60% perchloric acid is added dropwise under stirring . The ice-water bath was removed, the reaction mixture was returned to room temperature, and 0.056 mol of dry powdered glucose was added in batches under stirring to maintain the temperature of the reaction mixture at 30-40°C. Cool to 20 °C, add 0.1 mol (3.1 g) red phosphorus, and then add 0.226 mol (5.8 ml) bromine dropwise so that the temperature does not exceed 20 °C. After cooling, 3.6 mL of water was added with stirring to keep the reaction temperature not exceeding 20 ° C; the reaction mixture was left at room temperature for 2 h, diluted with 30 mL of dichloromethane, and filtered. Wash twice with 80 mL of ice water, then wash with 50 mL of saturated sodium bicarbonate solution (add ice so that the temperature does not exce...

Embodiment 2

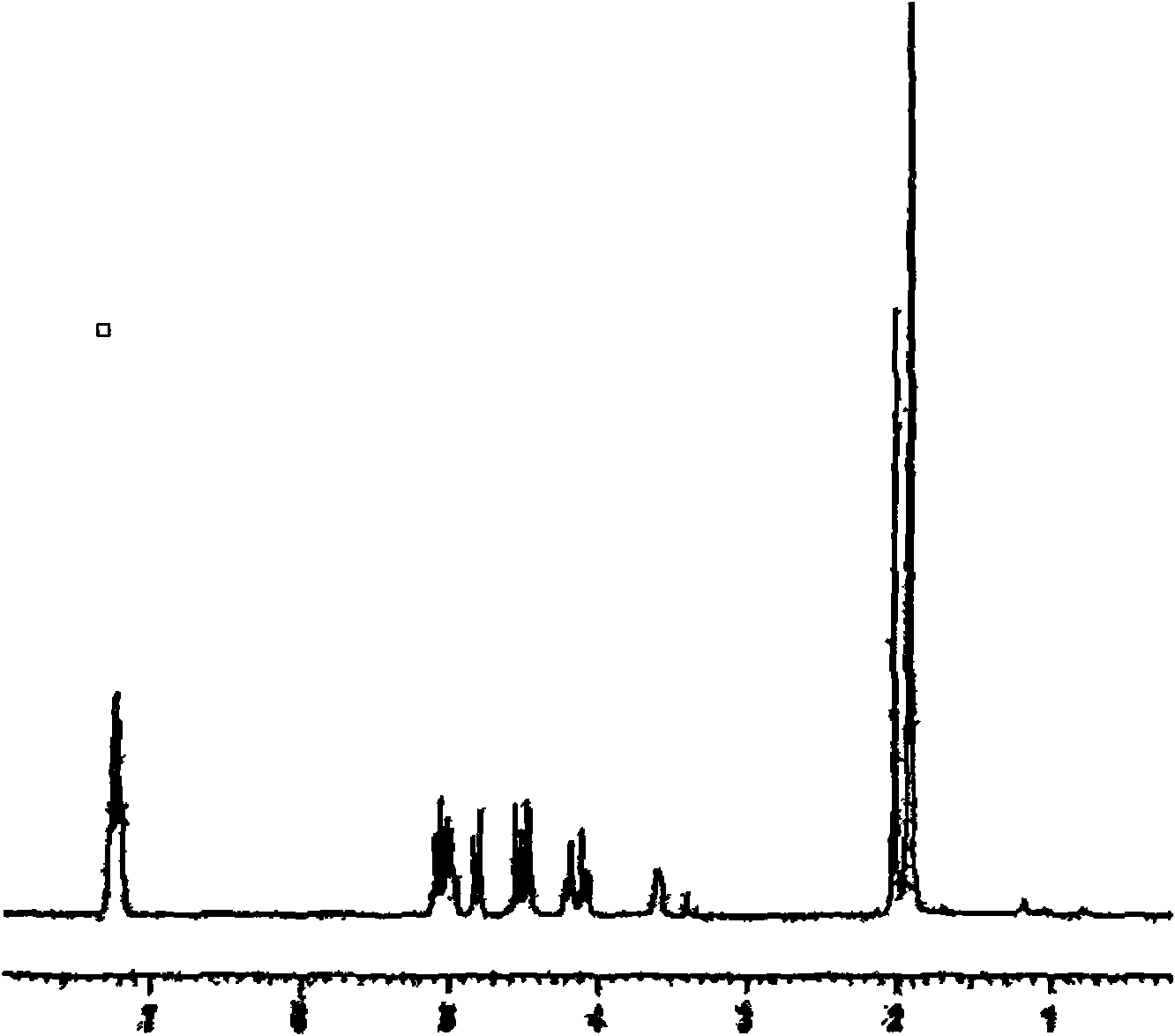

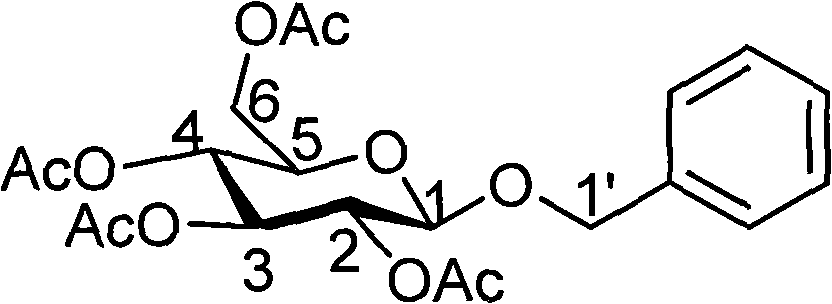

[0021] Example 2: The synthesis of benzyl 2,3,4,6-tetra-O-acetyl-β-D-glucopyranoside The specific operation process is as follows: In a 250mL round bottom flask, add 0.06mol (7.32g) Benzyl alcohol, 0.03mol (8.28g) silver carbonate, 10g anhydrous calcium sulfate, 50mL dichloromethane. The above mixture was stirred for half an hour. Dissolve 0.03mol (12.3g) of α-acetylglucosinobromide in 50mL of dichloromethane, add it to the above mixture, continue stirring for 24 hours, filter the mixture through a thin layer of diatomaceous earth, and distill off the solvent under reduced pressure; Purification by silica gel chromatography (petroleum ether: ethyl acetate = 5: 1) to obtain the pure product of benzyl 2,3,4,6-tetra-O-acetyl-β-D-glucopyranoside, m.p. 101-103°C, yield 92%.

[0022] The reaction process can be expressed as:

[0023]

[0024] The reaction steps of the present invention are simple, and the target compound can be obtained by only two steps of reaction, which are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com