Medium infrared parameter converter

An optical parametric oscillator, infrared light technology, applied in the laser field, can solve the problems of poor output laser beam quality, large pump light spot, limited coating level, etc., to reduce quantum number deficit, high nonlinear coefficient, high The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

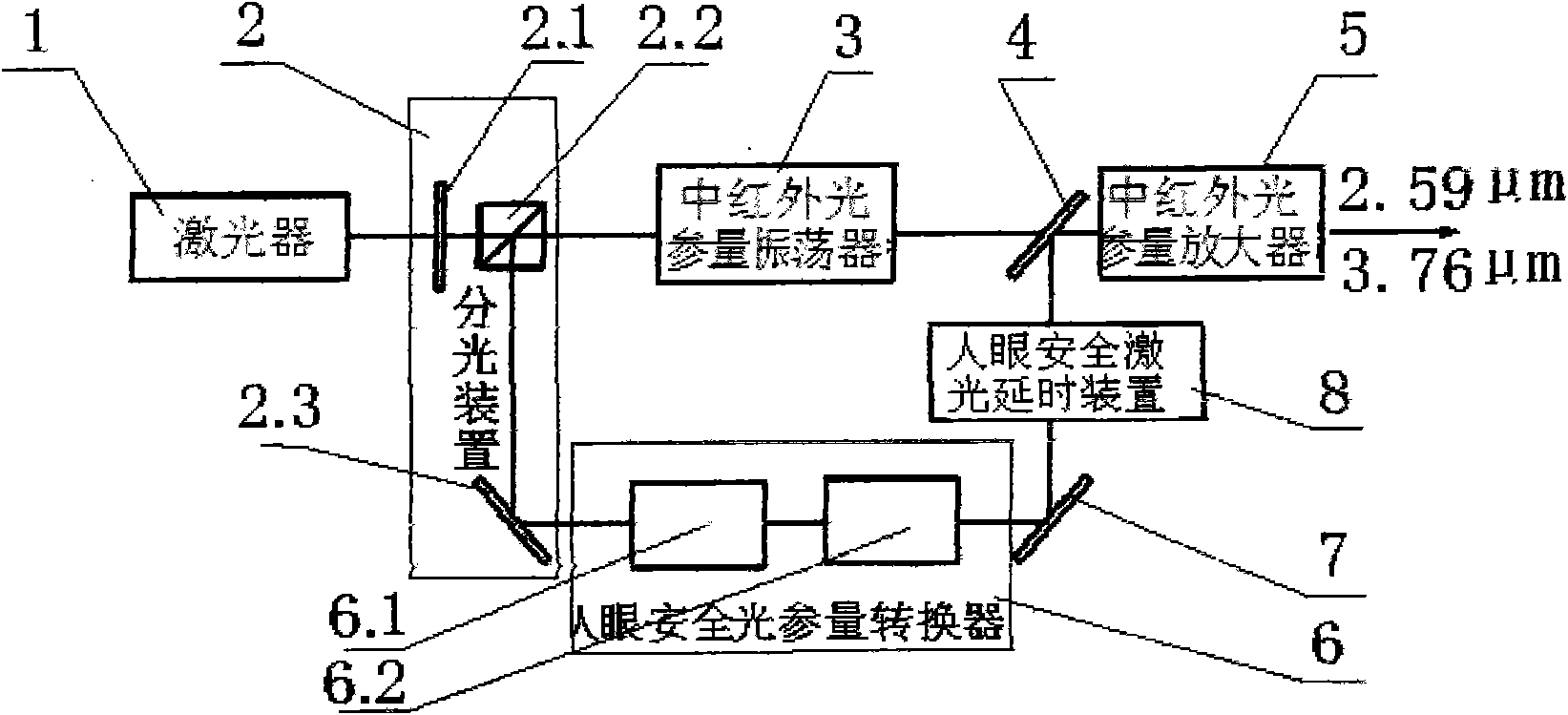

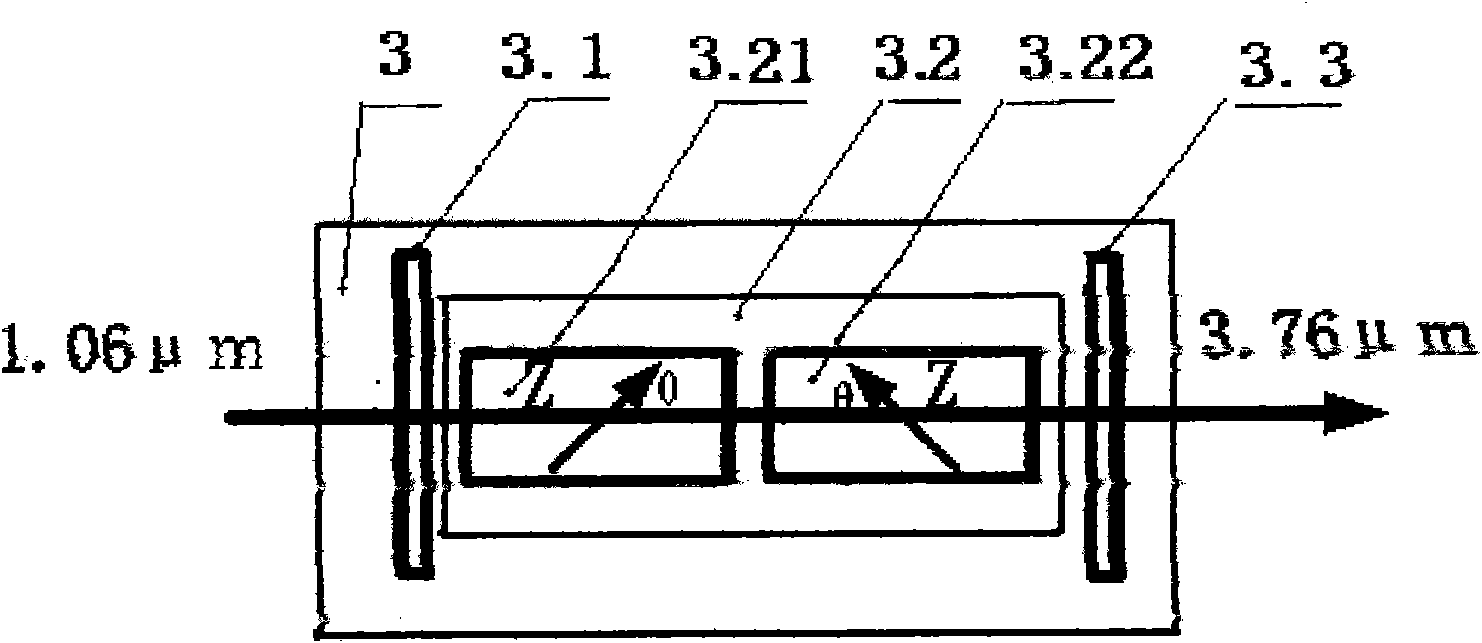

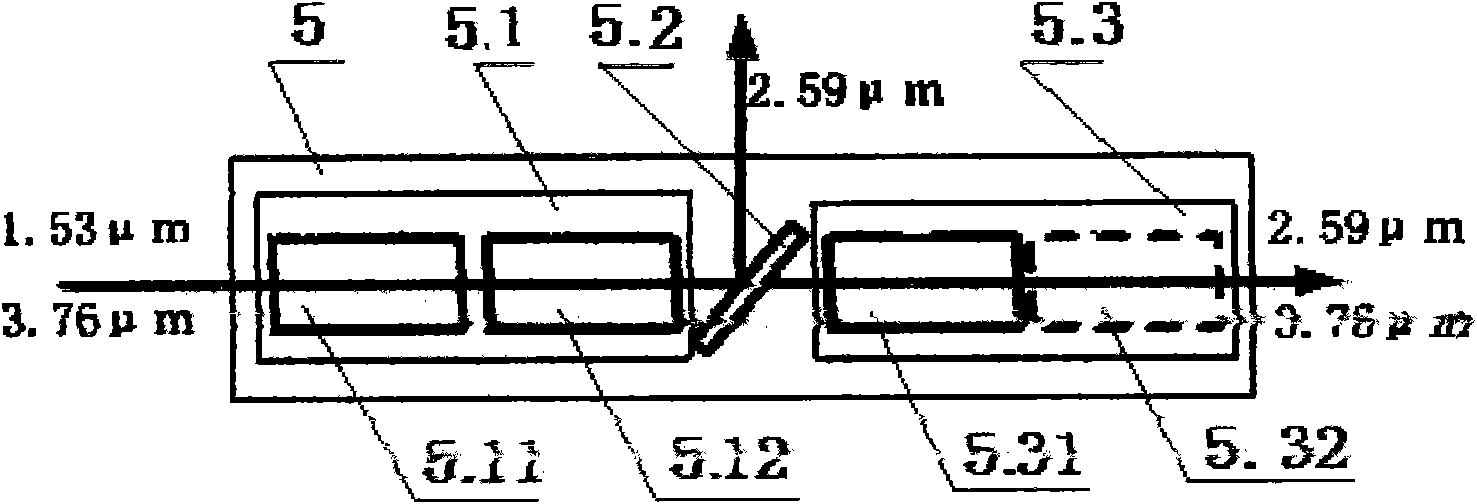

[0035] As shown in the figure: a mid-infrared optical parametric converter, the components arranged in sequence on the main optical path are: laser 1, spectroscopic device 2, mid-infrared optical parametric oscillator 3, two-color coupling mirror 4, mid-infrared optical parametric amplifier 5 The spectroscopic device 2 includes a wave plate 2.1, a polarizing device 2.2, and a spectroscopic reflector 2.3; in the direction of light path transmission of the spectroscopic reflector 2.3, the eye-safe optical parameter converter 6, the eye-safe laser reflector 7, and the human eye are successively Safety laser delay device 8; the laser 1 is a pump laser, and the light splitting device 2 divides the pump light into two paths: one path to pump mid-infrared light parametric oscillator 3 to generate mid-infrared light parametric seed light, and the other path To pump the eye-safe optical parameter converter 6 to generate eye-safe laser; the mid-infrared seed light is time-synchronized wi...

Embodiment 2

[0037] Different from Example 1, as attached Figure 5 As shown, the eye-safe optical parametric oscillator 6.1 is a ring resonator KTA optical parametric oscillator. 6.14. The input mirror of the eye-safe optical parametric oscillator of the ring cavity is composed of 6.15, the mirror one of the eye-safe optical parametric oscillator of the ring cavity 6.16 and the mirror two of the eye-safe optical parametric oscillator of the ring cavity 6.17. The remaining pump light from the oscillator 6.1 and the generated eye-safe signal light 1.53 μm enter the eye-safe optical parametric amplifier 6.2 together. The signal light 1.53μm is amplified and output, the cut angle of the KTA crystal in the eye-safe optical parametric oscillator 6.1 and the eye-safe optical parametric amplifier 6.2 is θ=90°, Ф=0°, both ends are coated with 1.06μm, 1.4~ 1.6 μm antireflection coating, and the Y-axis direction of the KTA crystal is parallel to the polarization direction of the 1.06 μm pump light ...

Embodiment 3

[0039] The difference from Embodiment 1 is: the mid-infrared optical parametric oscillator 3, the eye-safe optical parametric converter 6 and the mid-infrared optical parametric amplifier 5, wherein the mid-infrared optical parametric oscillator 3 is critical phase matching KTA light Parametric oscillator, the laser output wavelength is 3.95 μm; the KTA crystal cutting angle of the eye-safe optical parametric converter 6 and the mid-infrared optical parametric amplifier 5 is replaced by θ=90°, Ф=90°; the eye-safe optical parametric conversion The output wavelength of the amplifier 6 is 1.5 μm, and the output wavelengths of the mid-infrared optical parametric amplifier 5 are 3.95 μm and 2.42 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com