Method and device thereof for automatically peeling and splitting scrap electrical wires

An automatic and branching technology, which is applied in the direction of circuit, electrical components, electronic waste recycling, etc., can solve problems such as troublesome operation, low efficiency, and lack of automatic branching function, and achieve the effect of improving efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

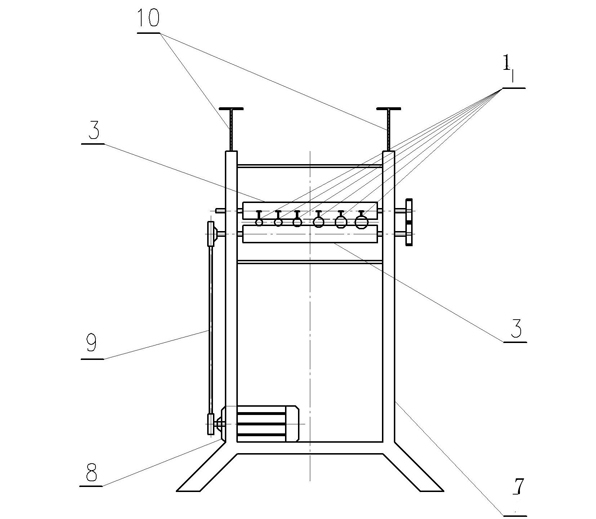

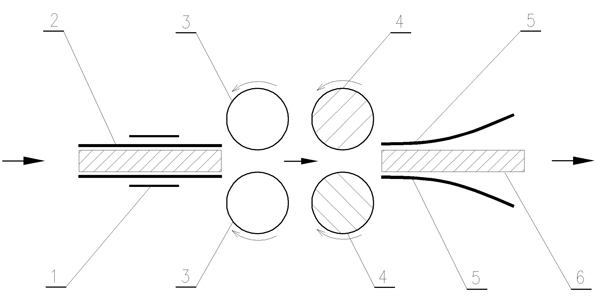

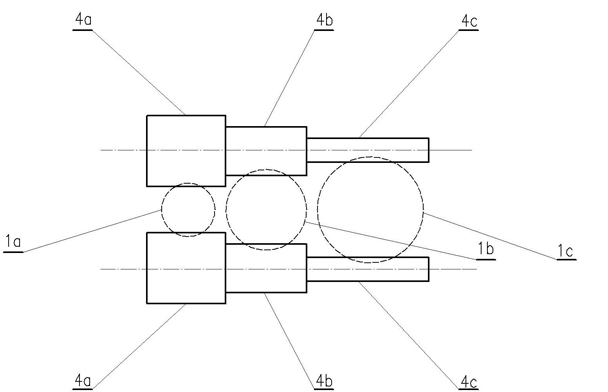

[0024] figure 1 Shown is a wire stripping machine with different diameters of wire inlet holes installed, which can handle different wire diameters. figure 2 After the waste electric wires 2 of different diameters shown are inserted from the round hole 1 of the nearest hole diameter, they are moved forward under the action of the rotating cutting knife 3, and at the same time, the outer layer of the package is cut open, and the line is further along the arrow The direction shown enters between the two rotatable pressing rollers 4 that are arranged subsequently, and under the action of the pressing rollers, the cut wrapping outer layer 5 is separated from the metal core 6 and discharged (in figure 2 The figure only shows the status of waste electric wires before they enter, and the status of the cladding layer and metal core after separation. In actual operation, the cladding layer and copper core are a continuous process from the entrance to the exit, and the wires are also ...

Embodiment 2

[0026] exist Figure 4 A rotating pressure roller 11 with teeth is installed between the round hole and the cutting knife of the shown wire stripping machine to drive the wires to move inwards for cutting, and the rest are the same as in Embodiment 1. In this example, the transmission mechanism adopts a belt drive. The outer wrapping layer contains thin wire waste wires with multiple strands of non-metallic wrapping layers and metal cores. The waste wires with an outer diameter of 5-80mm have good adaptability. Compared with the machine without pressure roller 4, the outer wrapping layer The ratio of separation from the internal thin lines has increased by about 72% from the original 20% to about 92%. If the thin wire in the outer wrapping layer is more than 5mm, it can be applied to this machine to separate the wrapping layer from the metal core. If it is a thin wire below 5mm, it can be separated by cutting and separating.

Embodiment 3

[0028] The structure of stripping machine is identical with embodiment 2, difference is in figure 1 The slitting knife of the wire stripper shown is not a rotating knife, but a Figure 5 Two fixed knives 12 arranged up and down are shown. When the waste electric wire passes in the direction indicated by the arrow, the fixed knife cuts the outer layer of the package, and then the outer layer of the package is separated from the metal core by the rear rotating pressure roller and discharged. The separation ratio of the cladding layer from the metal core is also close to that of the rotary knife machine, at 94-95%. After the fixed knife is used, it has a significant effect on the initial knife used, but due to the small action surface, heavy load, fast passivation, and frequent replacement. Therefore, it is more suitable for cables with thicker coatings. In addition, if the wrapping layer contains wires of materials such as hemp rope, it is more suitable for the models shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com