Nepheline glass ceramic and metal powder composite material and preparation method thereof

A technology of glass-ceramic powder and glass-ceramic, applied in the field of new materials, can solve problems such as the inability to realize the combination of glass and metal, and achieve the effects of improving mechanical properties, expanding application fields, and reducing overproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

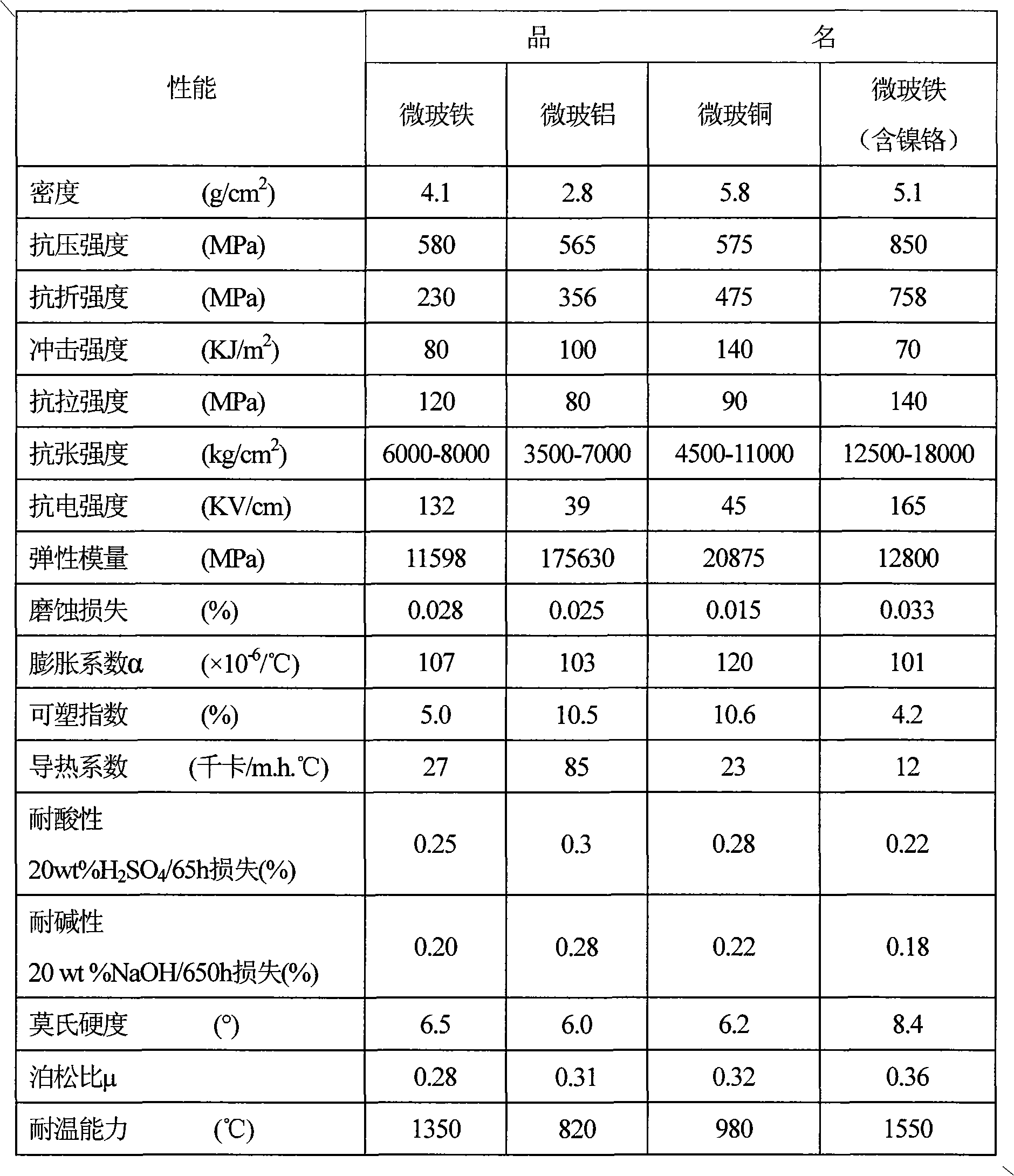

Image

Examples

preparation example Construction

[0026] The method for preparing nepheline glass-ceramic and metal powder composite material of the present invention has the following specific steps:

[0027] (1) Grind the nepheline glass-ceramic water-quenched particles with a ball mill or other grinding equipment into 100-300 mesh fine powder, and then mix the 100-500 mesh metal powder and whiskers with the glass-ceramic powder 2- 3 hours;

[0028] (2) Cold-press forming the mixed powder uniformly mixed in step (1) with a 100-500 ton press, and determine according to the specifications of the blank, the pressure: 120-150MPa, and the rectangular blank is molded;

[0029] (3) Put the blank of step (2) into a roller kiln or a bell jar crystallization kiln for sintering and crystallization at a temperature of 850-1400°C (aluminum-based composite material 850-950°C, copper-based composite material 900-1050°C, Iron-based composite material 1000-1400℃, time 60-240 minutes);

[0030] (4) The billet after step (3) crystallized into the ho...

Embodiment 1

[0035] In terms of parts by weight, the composition of the composite material of nepheline glass-ceramics and metal powder in this embodiment is as follows:

[0036] Glass-ceramic powder 30; iron powder 55 parts; other metal powder 10 parts (including tungsten powder, chromium powder, lithium powder, nickel powder, lead powder each 2 parts); whisker silicon 5 parts. In the present invention, the whiskers are silicon whiskers (also known as short silicon fibers, 2-15 microns in length and 0.001-0.002 microns in diameter).

[0037] The method for preparing the nepheline glass-ceramics and metal powder composite material of this embodiment, the specific steps are as follows:

[0038] (1) Grind the nepheline glass-ceramic water-quenched particles with a ball mill or other grinding equipment into 150 mesh fine powder, and then mix and grind 100-300 mesh metal powder and whiskers with the glass-ceramic powder for 2.5 hours;

[0039] (2) The mixed powder mixed uniformly in step (1) is molded...

Embodiment 2

[0046] The difference from Example 1 is:

[0047] In terms of parts by weight, the composition of the composite material of nepheline glass-ceramics and metal powder in this embodiment is as follows:

[0048] 70 parts of glass-ceramic powder; 20 parts of iron powder; 10 parts of other metal powder (including 2 parts of tungsten powder, chromium powder, lithium powder, nickel powder, and lead powder); 10 parts of whisker silicon.

[0049] The method for preparing the nepheline glass-ceramics and metal powder composite material of this embodiment, the specific steps are as follows:

[0050] (1) Grind the nepheline glass-ceramic water-quenched particles with a ball mill or other grinding equipment into 150 mesh fine powder, and then mix and grind the 100-300 mesh metal powder and whisker with the glass-ceramic powder for 2 hours;

[0051] (2) The mixed powder mixed uniformly in step (1) is molded by a 300-ton press, and determined according to the specifications of the blank, the pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com