Method for preparing yttrium oxide substrate nano-oxide fluorescent powder

A technology of nano-oxide and fluorescent powder, which is applied in the field of nano-fluorescent materials to achieve the effects of good dispersion, cheap raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

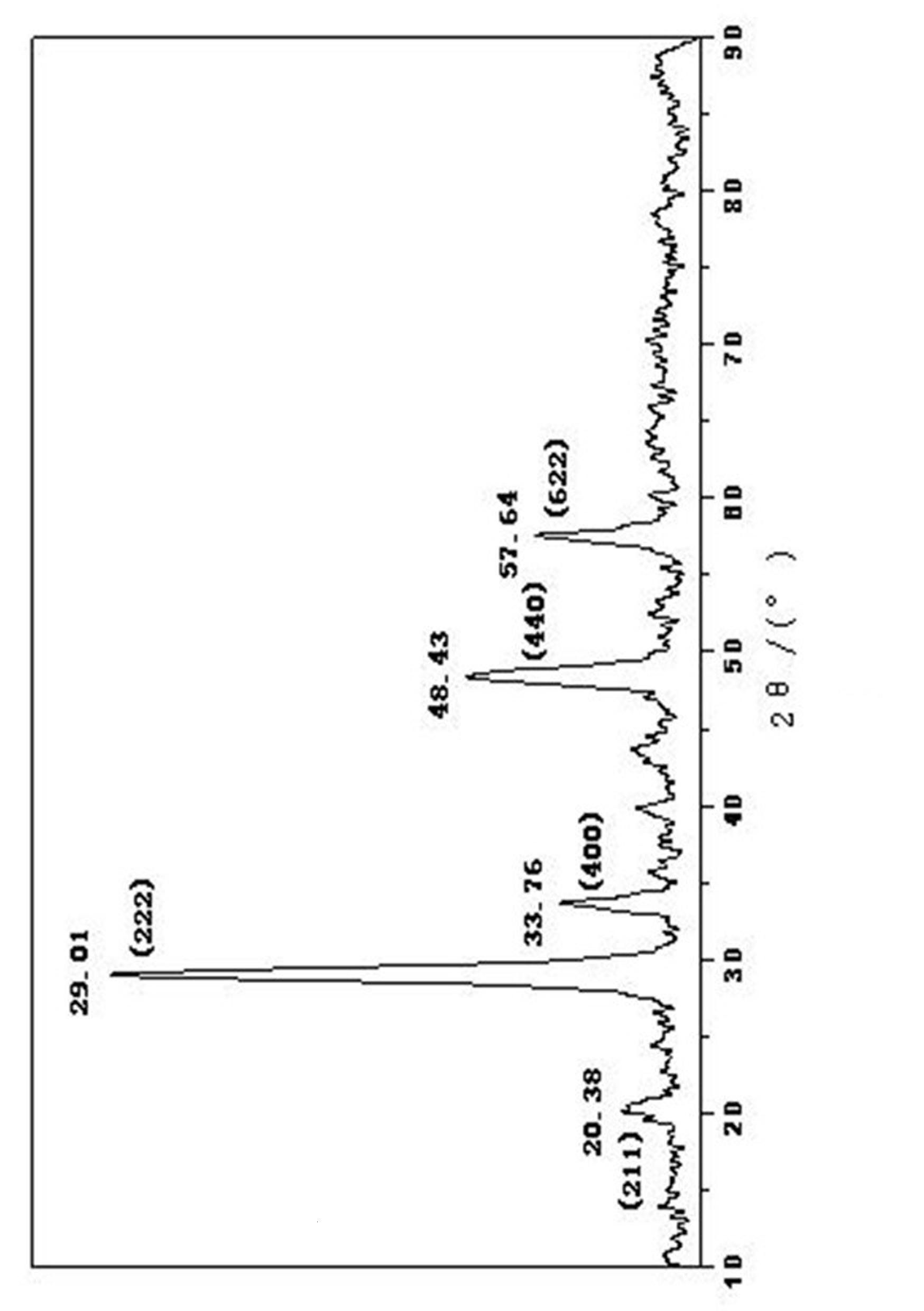

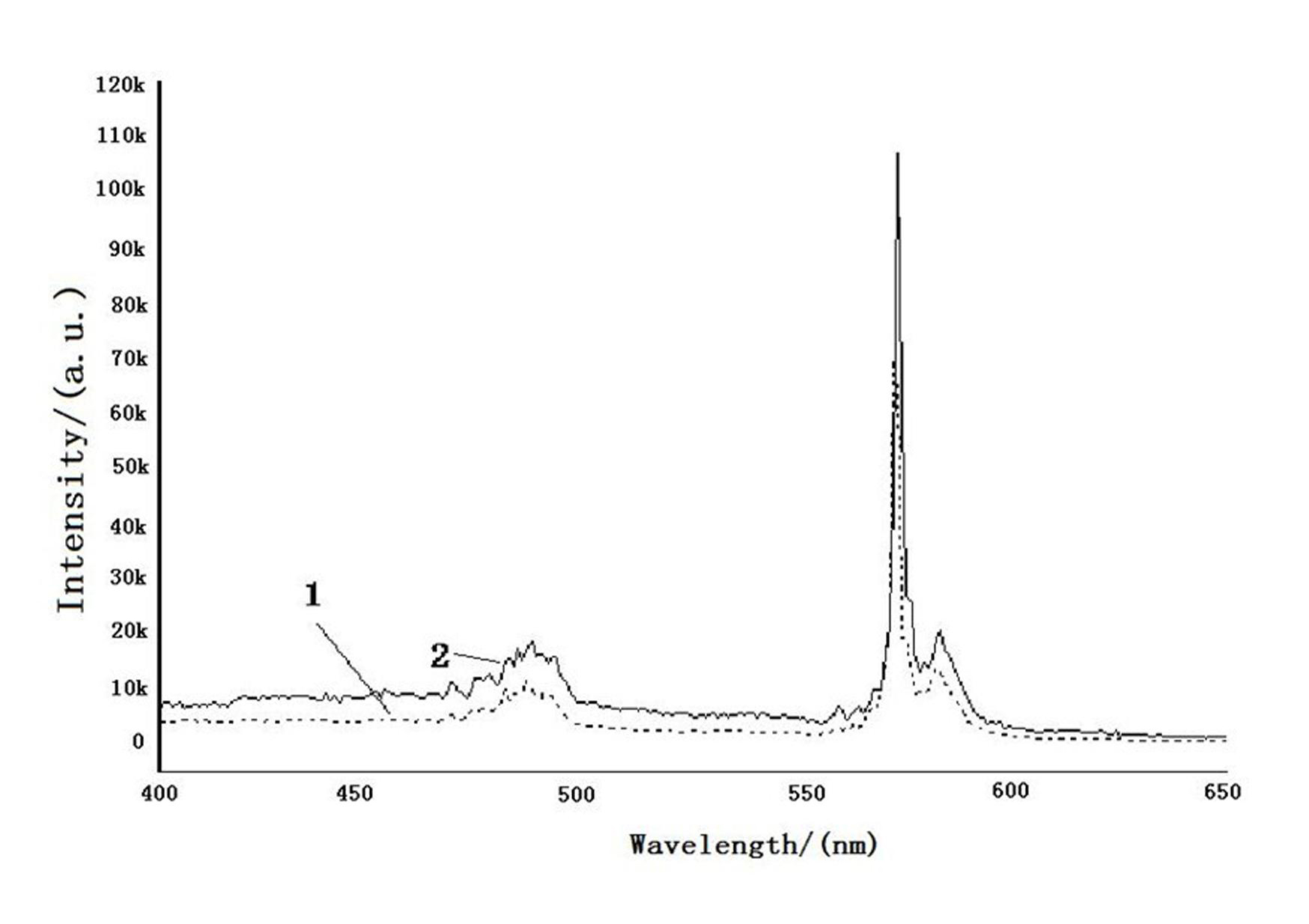

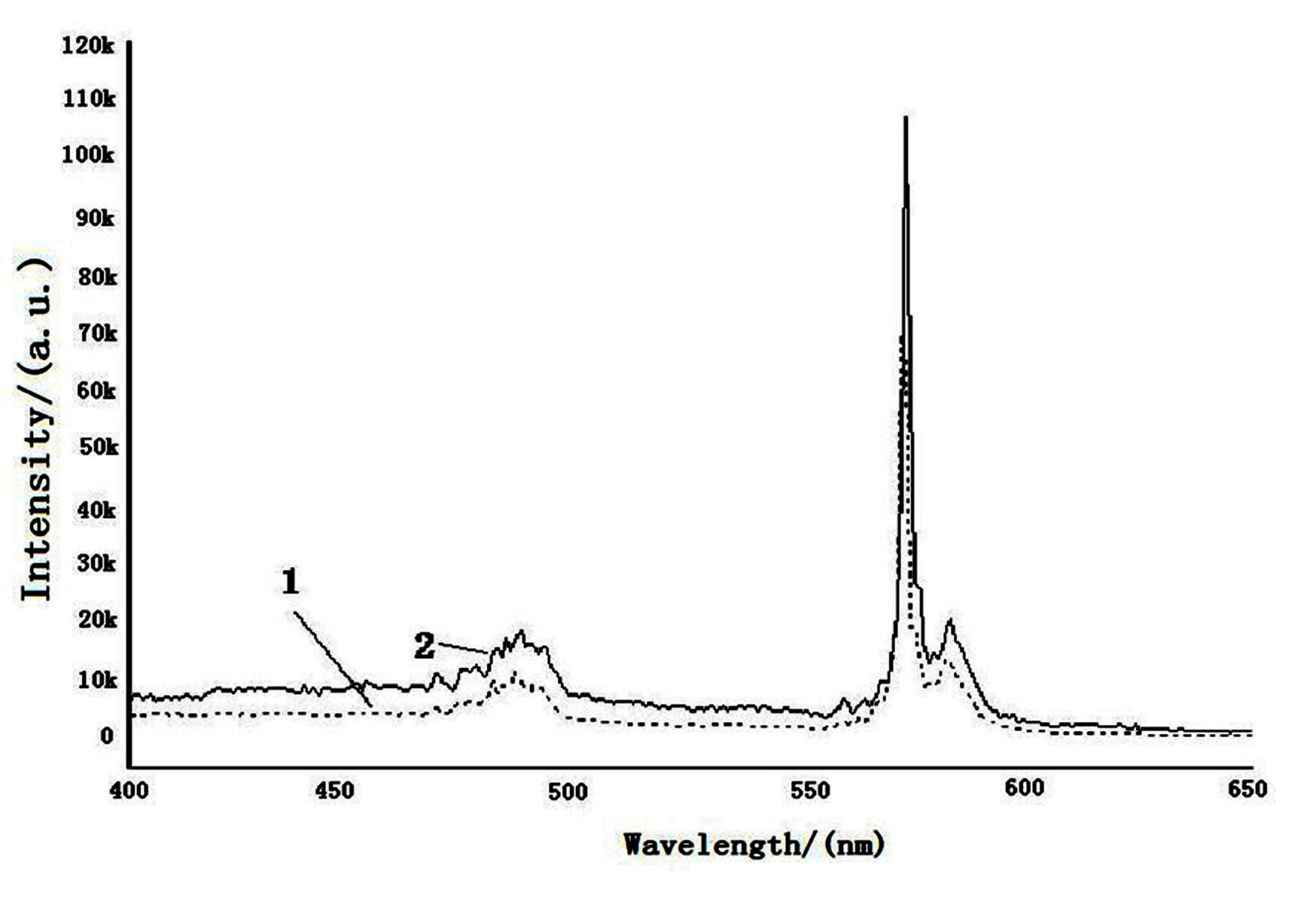

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 0.1915 g of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O), 0.0009g dysprosium oxide (Dy 2 o 3 ) into a 100ml beaker, add 0.126ml of 36% concentrated hydrochloric acid, heat to dissolve, and then add 10ml of deionized water to make a mixed solution of rare earth ions. At this time, the molar ratio of rare earth ions is Y 3+ : Dy 3+ =1:0.01;

[0028] (2) Weigh 0.3554g G5.0 PAMAM (fifth-generation polyamide-amine dendrimer) and dissolve it in deionized water to obtain a PAMAM aqueous solution. Use 0.01 mol·L -1 dilute hydrochloric acid to adjust the pH value of the aqueous solution to 5.0;

[0029] (3) Weigh 5.325g ammonium oxalate ((NH 4 ) 2 C 2 o 4 ·H 2 O) Dissolve in 250ml deionized water to make a concentration of 0.15 mol L -1 ammonium oxalate solution;

[0030] (4) Slowly add the rare earth ion mixed solution pre-prepared in step (1) into the G5.0 PAMAM aqueous solution under rapid stirring, and fully react for 24 hours;

[0031] (5) Add 10...

Embodiment 2

[0035] (1) Weigh 0.1915 g of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O), 0.0019g dysprosium oxide (Dy 2 o 3 ) into a 100ml beaker, add 0.126ml of 36% concentrated hydrochloric acid, heat to dissolve, and then add 10ml of deionized water to make a mixed solution of rare earth ions. At this time, the molar ratio of rare earth ions is Y 3+ : Dy 3+ =1:0.02;

[0036](2) Weigh 0.3554g G5.0 PAMAM (fifth-generation polyamide-amine dendrimer) and dissolve it in deionized water to obtain a PAMAM aqueous solution. Use 0.01 mol·L -1 dilute hydrochloric acid to adjust the pH to 5.0;

[0037] (3) Weigh 5.325g ammonium oxalate ((NH 4 ) 2 C 2 o 4 ·H 2 O) Dissolve in 250ml deionized water to make a solubility of 0.15 mol L -1 ammonium oxalate solution;

[0038] (4) Slowly add the rare earth ion mixed solution pre-prepared in step (1) into the PAMAM aqueous solution under rapid stirring, and fully react for 24 hours;

[0039] (5) Add ammonium oxalate solution dropwise to the...

Embodiment 3

[0043] (1) Weigh 0.1915 g of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O), 0.0028g of dysprosium oxide was placed in a 100ml beaker, 0.126ml of 36% concentrated hydrochloric acid was added to heat and dissolve, and then 10ml of deionized water was added to form a mixed solution of rare earth ions. The molar ratio of rare earth ions was Y 3+ : Dy 3+ =1︰0.03;

[0044] (2) Weigh 0.3554g G5.0 PAMAM (fifth-generation polyamide-amine dendrimer) and dissolve it in deionized water to obtain a PAMAM aqueous solution. Use 0.01 mol·L -1 dilute hydrochloric acid to adjust the pH to 5.0;

[0045] (3) Weigh 5.325g ammonium oxalate ((NH 4 ) 2 C 2 o 4 ·H 2 O) Dissolve in 250ml deionized water to make a solubility of 0.15 mol L -1 ammonium oxalate solution;

[0046] (4) Slowly add the rare earth ion mixed solution pre-prepared in step (1) into the G5.0 PAMAM aqueous solution under rapid stirring, and fully react for 24 hours;

[0047] (5) Add 10 ml of ammonium oxalate solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com