Method for producing low-salt fish sauce

A production method and technology of fish soy sauce, which is applied in the field of low-salt fish soy sauce production, can solve problems such as environmental pollution and waste of resources, and achieve the effects of increasing added value, reducing fishy smell, and expanding consumption areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of sauce grains: Add 2kg of distilled water, 4kg of crushed blue squid into a 10L plastic bucket, add 22.5% of fish weight salt and 10% of fish weight of crushed shrimp heads, stir well to prepare sauce grains .

[0028] In the traditional fish soy sauce preparation process, in order to prevent the raw materials from spoiling during the fermentation process, saturated salt is usually used to inhibit the reproduction of spoilage microorganisms, so the salt content of the produced fish soy sauce is more than 25%. With the improvement of people's living standards and the emphasis on dietary health, low-salt fish soy sauce as a condiment for daily life has gradually attracted the attention of consumers. Japan has carried out a large number of experiments on salt-reduced soy sauce, showing that 9% of the salt in soy sauce is the most suitable for patients whose salt intake is restricted. However, when the salt content in the soy sauce is less than 10%, the sh...

Embodiment 2

[0033] 1, the preparation of sauce unstrained spirits: preparation method is identical with example 1.

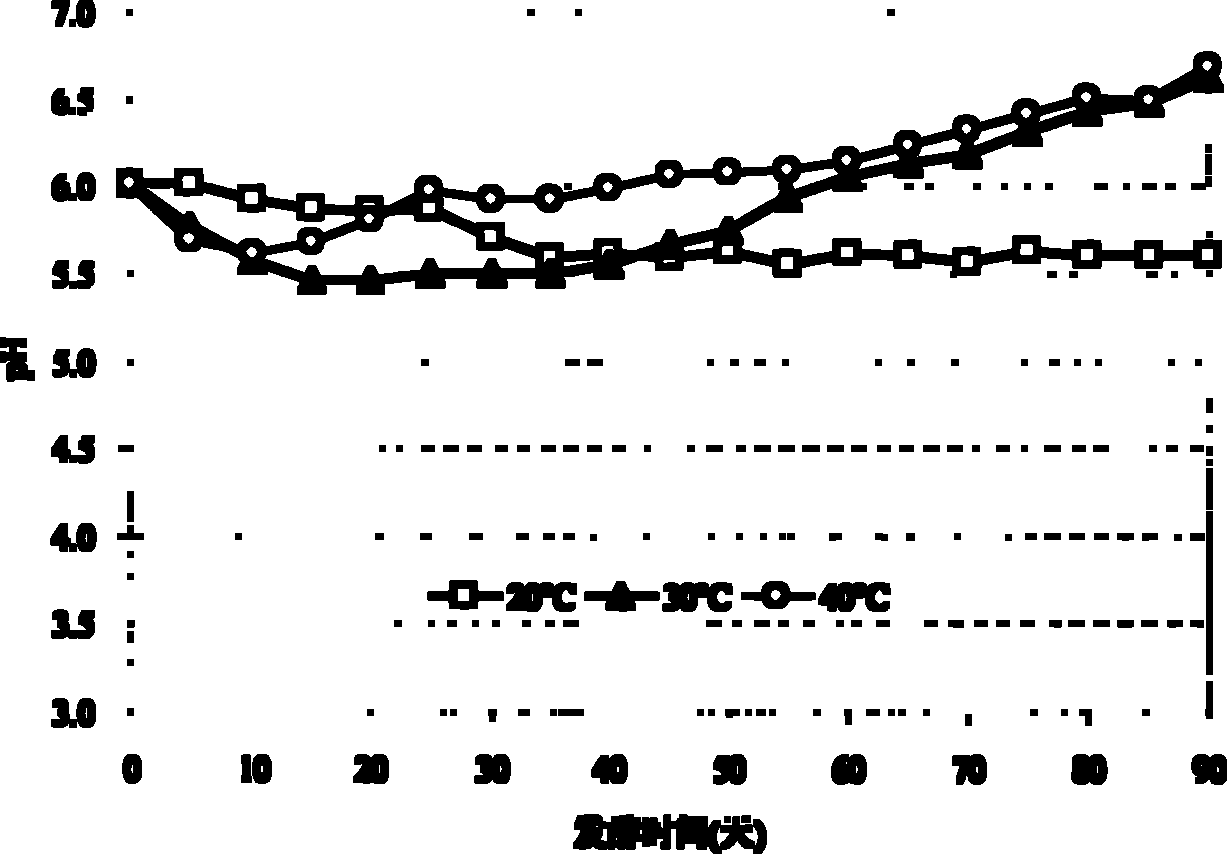

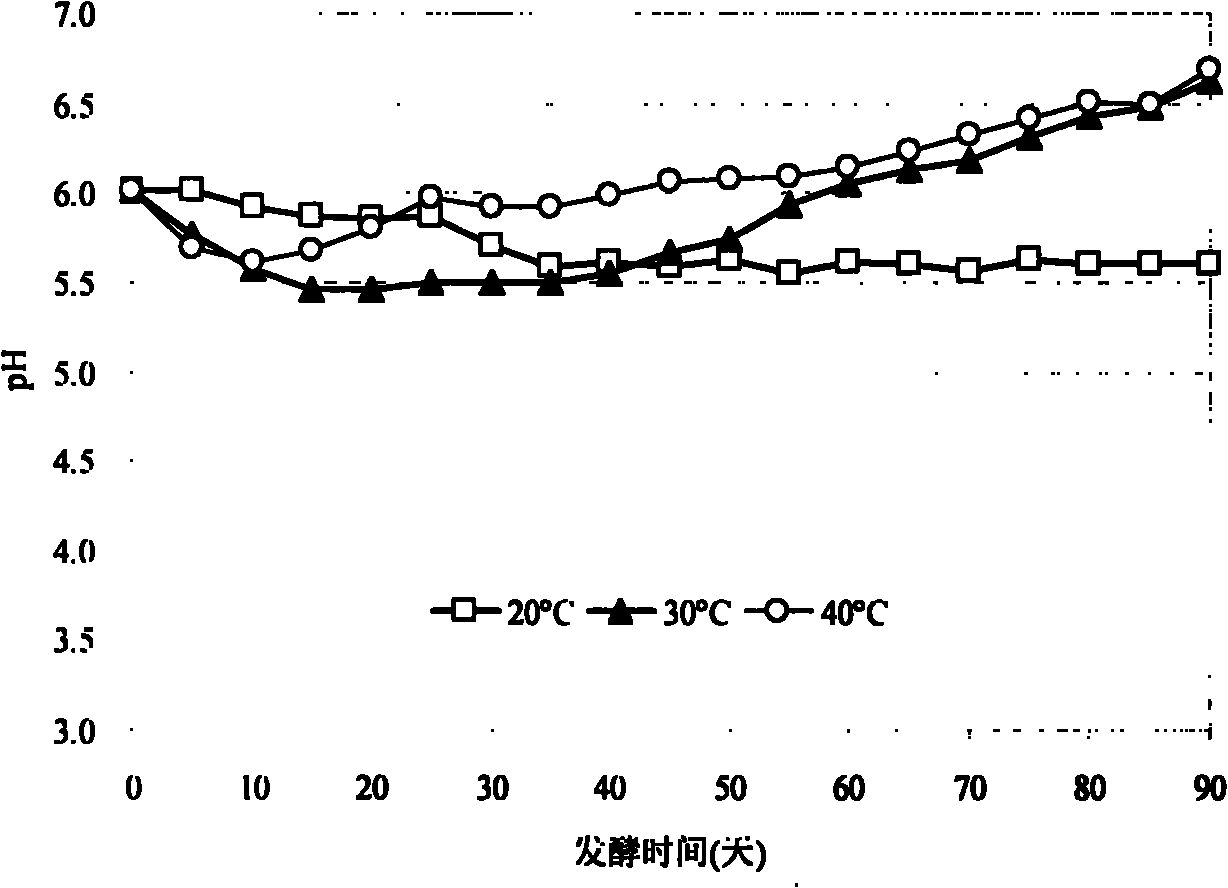

[0034] 2. Fermentation: Place the prepared sauce grains at 30°C for enzymatic fermentation and fermentation for 90 days. During the fermentation period, stir once a day to make the fermentation even and rapid. Trend, after 90 days of fermentation, the pH of the fermentation broth reached 6.6.

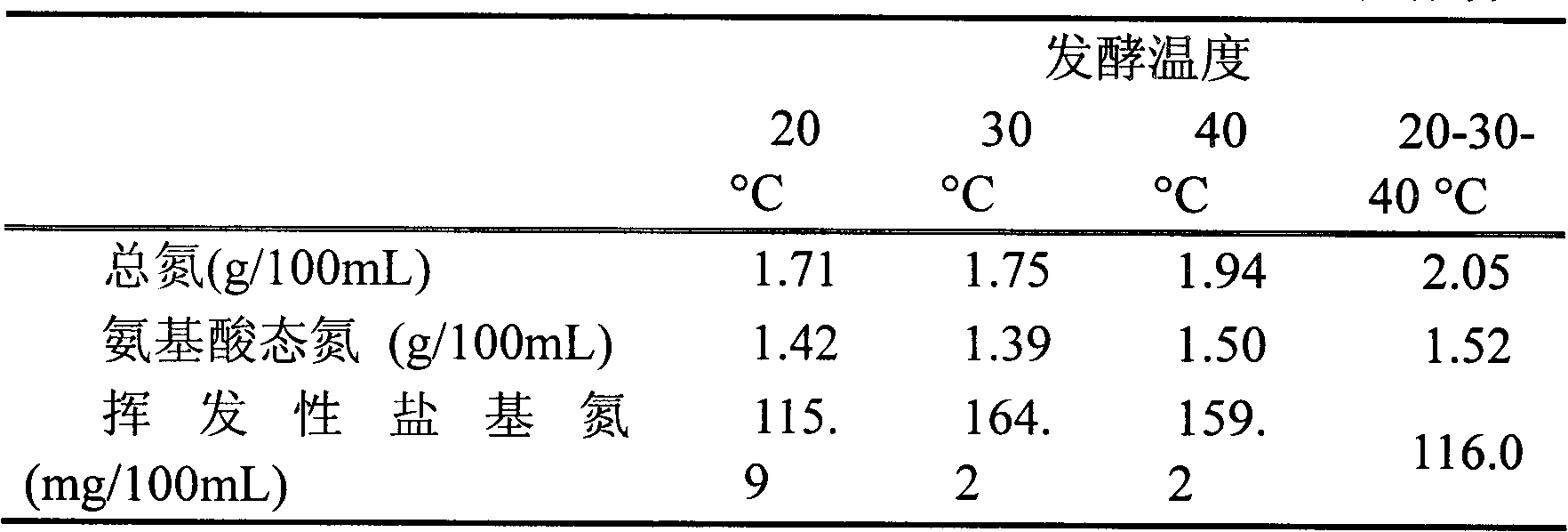

[0035]3. Extraction of fish soy sauce: after 3 months of fermentation, extract the fish soy sauce with a salt content of 15% according to the extraction method of Example 1, the total nitrogen, amino acid nitrogen, volatile base nitrogen and free amino acids, etc. of the fish soy sauce The measurement results of physical and chemical indicators are shown in Table 1 and Table 2.

Embodiment 3

[0037] 1, the preparation of sauce unstrained spirits: preparation method is identical with example 1.

[0038] 2. Fermentation: place the prepared fermented soy sauce grains at 40°C for enzymolysis and fermentation, ferment for 90 days, and stir once a day during the fermentation period to make the fermentation even and rapid. Similarly, after 90 days of fermentation, the pH of the broth reached 6.7.

[0039] 3. Extraction of fish soy sauce: after 3 months of fermentation, extract the fish soy sauce with a salt content of 15% according to the extraction method of Example 1, the total nitrogen, amino acid nitrogen, volatile base nitrogen and free amino acids, etc. of the fish soy sauce The measurement results of physical and chemical indicators are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com