Starch/polylactic acid antibacterial activity packaging material as well as preparation method and application thereof

An antibacterial activity, packaging material technology, applied in packaging, wrapping paper, transportation and packaging, etc., to achieve both antibacterial timeliness and long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

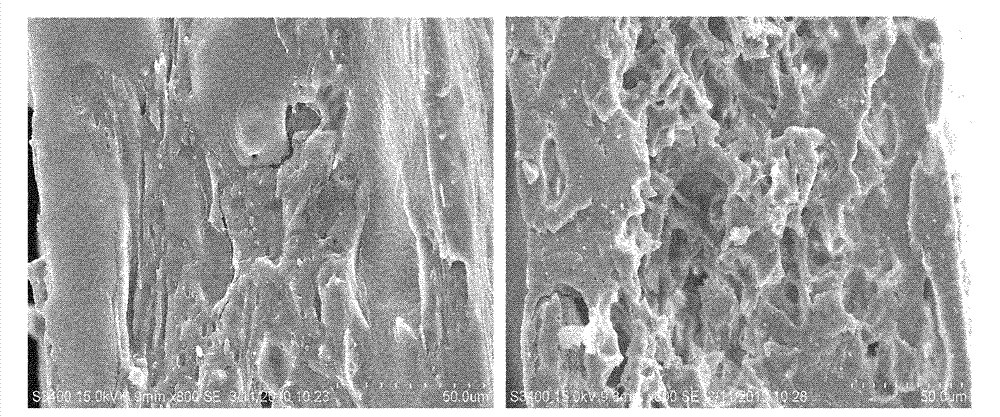

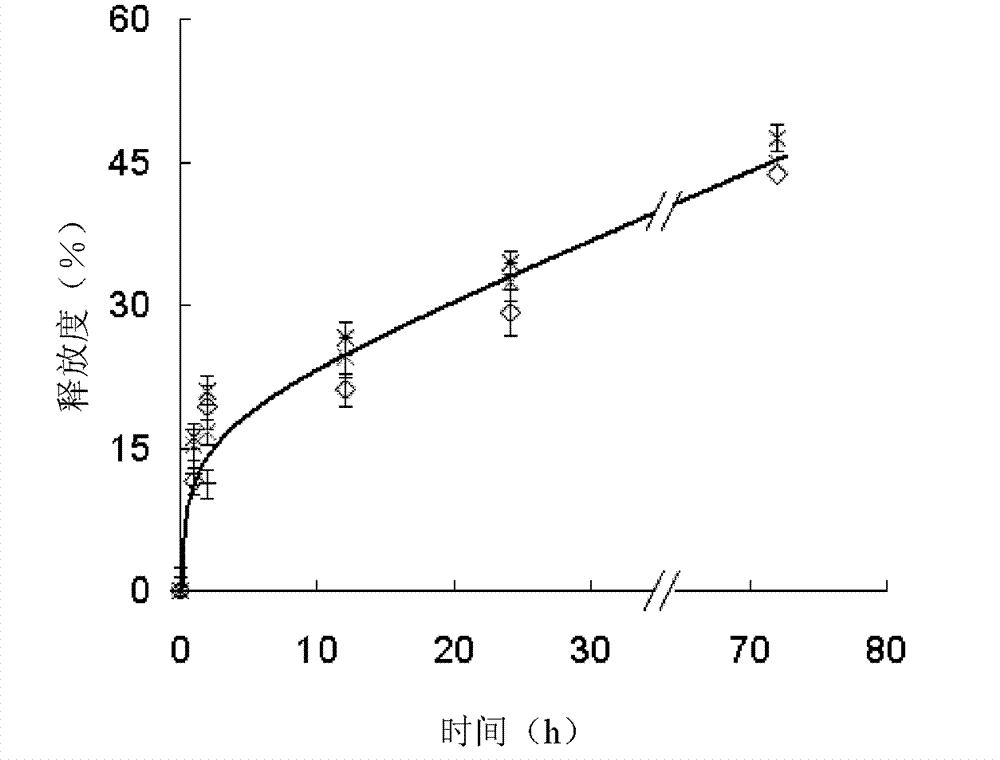

Method used

Image

Examples

Embodiment 1

[0038] Polylactic acid (REVODE101, Zhejiang Hisun Biomaterials Co., Ltd.): 60kg

[0039] Corn starch (food grade, Huanglong Food Industry Co., Ltd.): 30kg, dried to a moisture content of 0.5%

[0040] Diphenylmethane-4,4-diisoate (chemically pure, Xiamen Lufa Trade Development Co., Ltd.): 0.01kg

[0041] Chitosan (food grade, deacetylation degree 90%, Jinan Haidebei Marine Biological Engineering Co., Ltd.): 9.99kg.

[0042] The preparation method is as follows:

[0043] (1) starch plasticization

[0044] Dry the starch until the moisture content is 0.5%, add 1-2% glycerin (glycerin / starch, w / w), mix evenly, feed from the first feeding port of the twin-screw extruder, and convey through the screw conveying section, Pre-plasticized under the condition of external heating of the screw, the pre-plasticized temperature is 140°C, the pre-plasticized starch is further plasticized under the action of the kneading screw block, the plasticized temperature is 170°C, the outer diameter...

Embodiment 2

[0057] Each component in the blended material is adjusted to:

[0058] Polylactic acid (REVODE101, Zhejiang Hisun Biomaterials Co., Ltd.): 45kg

[0059] Potato starch (food grade, Qinghai Sanjiang Group Co., Ltd.): 44kg, dried to a moisture content of 1.0%

[0060] Diphenylmethane-4,4-diisoate (chemically pure, Xiamen Lufa Trade Development Co., Ltd.): 1kg Nisin (food grade, Xiamen Abio Biotechnology Co., Ltd.): 10kg.

[0061] The preparation method is the same as in Example 1.

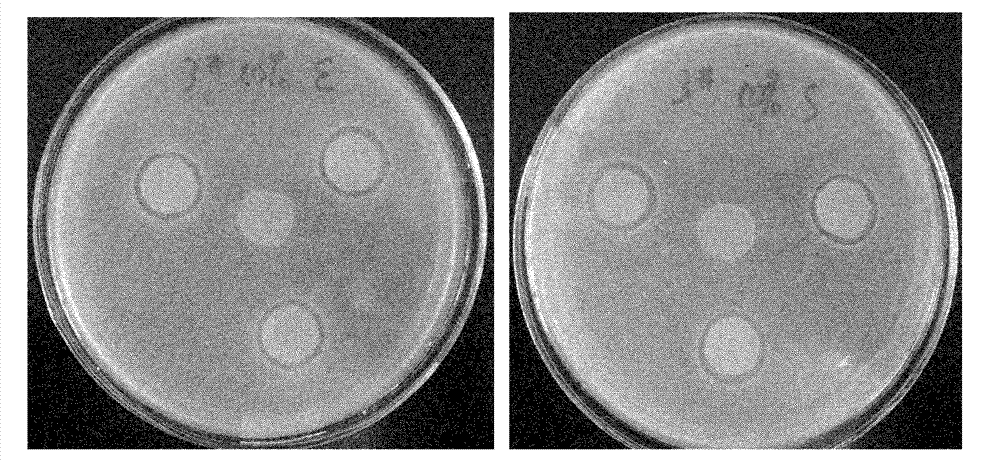

[0062] (1) The prepared antibacterial material was used for the packaging of fresh pork (Guangzhou China Resources Wanjia Supermarket, the same below), stored at 4°C for one week, according to the national standard GB / T4789.17-2003 "Food Hygiene Microbiology The method specified in "Inspection of Meat and Meat Products Inspection" tests the number of Escherichia coli and Staphylococcus aureus, and the results are shown in Table 2.

[0063] (2) The prepared antibacterial material was used for the pa...

Embodiment 3

[0067] Each component in the blended material is adjusted to:

[0068] Polylactic acid (REVODE101, Zhejiang Hisun Biomaterials Co., Ltd.): 60kg

[0069] High-chain starch (Hylon V, food grade, American National Starch Company): 35kg, dried to a moisture content of 0.5%

[0070] Diphenylmethane-4,4-diisoate (chemically pure, Xiamen Lufa Trade Development Co., Ltd.): 0.05kg

[0071] Lysozyme (lysozyme, food grade, Jinan Xuyunchuang Biotechnology Co., Ltd.): 4.95kg.

[0072] The preparation method is the same as in Example 1.

[0073] The mechanical properties, thermal properties and barrier properties of the prepared antibacterial active packaging materials were tested, and the results are shown in Table 2. The material is used for the packaging of fresh pork, fresh chicken and homemade ham sausage (without preservatives), the total number of colonies and the number of Escherichia coli and Staphylococcus aureus in the food are tested before packaging, and they are stored at 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com