Self-assembly nano-particles of sulfhydrylation chitosan quaternary ammonium salt and preparation method and application thereof

A technology of chitosan quaternary ammonium salt and chitosan quaternary amine, which is applied in the field of nanoparticles, can solve problems such as poor solubility, achieve simple process, promote intestinal absorption, and prevent drug inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

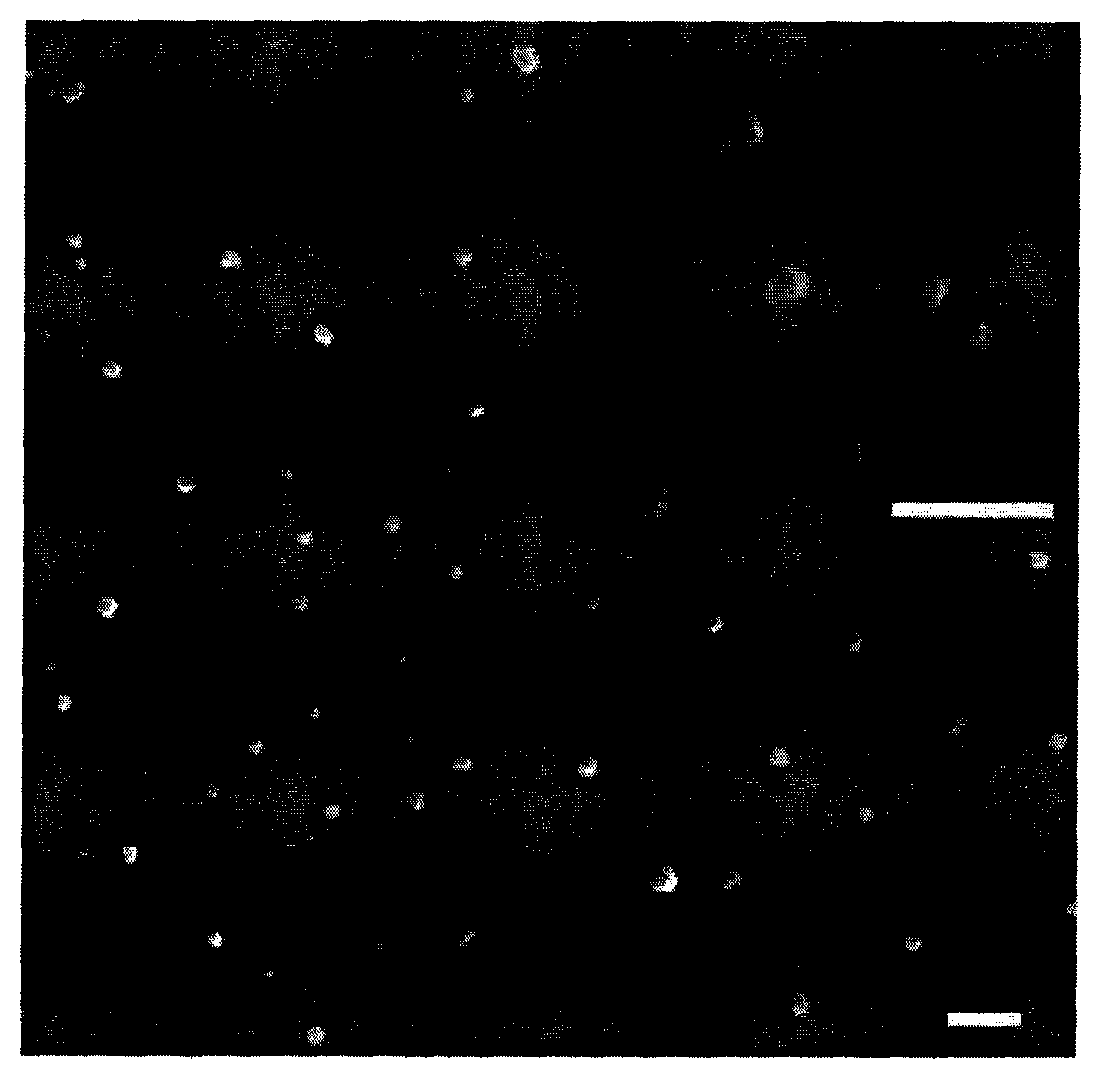

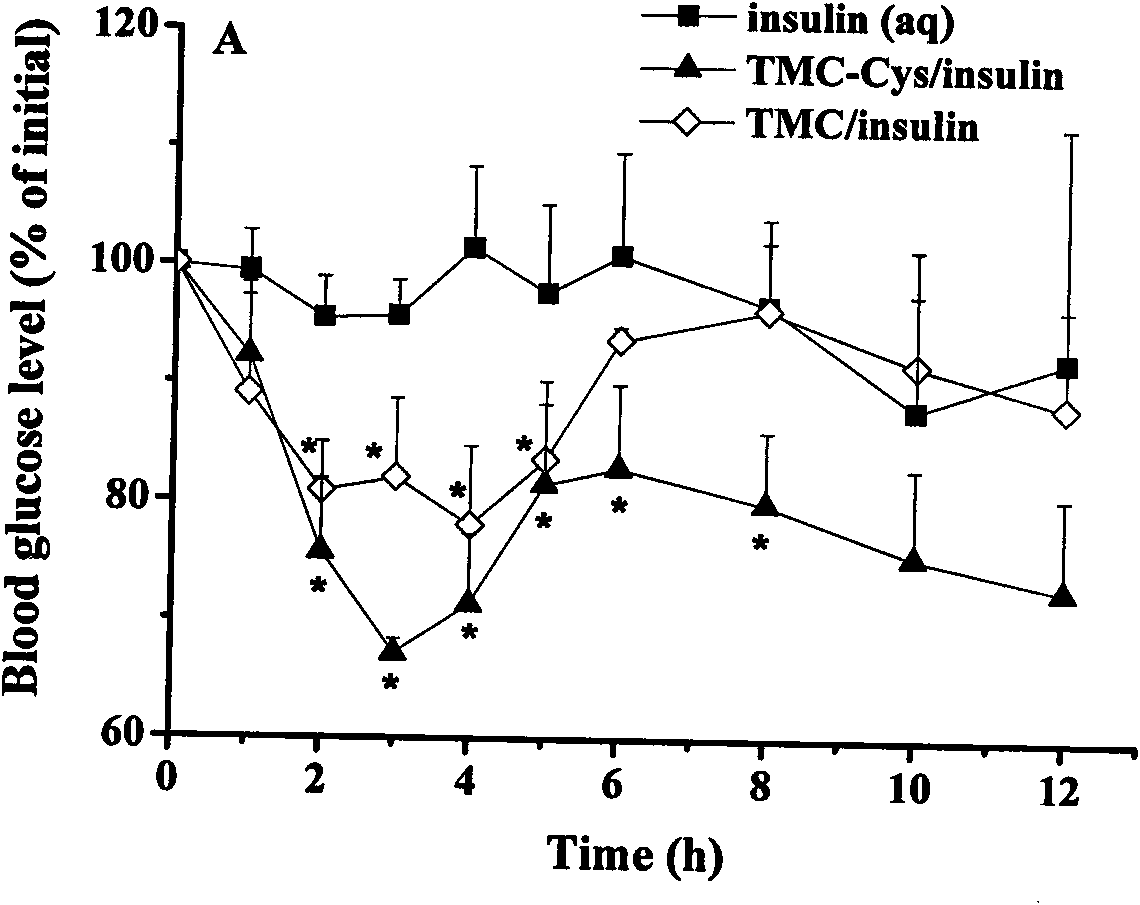

Image

Examples

Embodiment 1

[0063] Embodiment 1 The preparation of chitosan quaternary ammonium salt-cysteine copolymer

[0064] According to the literature report method (Eur J Pharm Biopharm 2004,57:77-83) synthetic TMC, chitosan weight-average molecular weight is 30kDa, and reaction time is respectively 45min, 120min, 180min and 240min, and the degree of quaternization of gained TMC is respectively 15%, 30%, 60%, and 80%. Cl - Purify with anion exchange resin, freeze-dry; weigh 500mg TMC and dissolve in 50mL water, 2g cysteine dissolve in 20mL water, mix, add EDAC and NHS with a final concentration of 300mM respectively, adjust the pH to 5.0, and react at room temperature for 5h. The reaction product was dialyzed against pH 5.0 HCl solution (MWCO 3500Da) at 4°C for 5 days, and freeze-dried. The reaction conditions of the blank control were the same except that EDAC / NHS was not added.

Embodiment 2

[0065] Embodiment 2 The preparation of chitosan quaternary ammonium salt-cysteine copolymer

[0066] Synthesize TMC according to literature report method (Eur J Pharm Biopharm 2004,57:77-83), chitosan molecular weight is weight average 100kDa, reaction time is respectively 45min, 120min, 180min and 240min, the quaternization degree of gained TMC is respectively 15%, 30%, 60%, and 80%. Cl - Purify TMC with anion-exchange resin, freeze-dry; weigh 500mg TMC, dissolve in 50mL water, and dissolve 2g cysteine in 20mL water, mix, add EDAC and NHS with a final concentration of 300mM respectively, adjust the pH to 3.0, and react at room temperature for 5h , the reaction product was dialyzed against pH 5.0 HCl solution (MWCO3500Da) at 4°C for 5 days, and freeze-dried. The reaction conditions of the blank control were the same except that EDAC / NHS was not added.

Embodiment 3

[0067] Embodiment 3 The preparation of chitosan quaternary ammonium salt-cysteine copolymer

[0068] According to the literature report method (Eur J Pharm Biopharm 2004,57:77-83) synthetic TMC, chitosan weight average molecular weight is 200kDa, and reaction time is respectively 45min, 120min, 180min and 240min, and the degree of quaternization of gained TMC is respectively 15%, 30%, 60%, and 80%. Purify TMC with Cl-type anion exchange resin, dialyze, and freeze-dry; weigh 500mg TMC and dissolve it in 50mL water, and dissolve 2g cysteine in 20mL water, mix, add EDAC and NHS with a final concentration of 300mM respectively, and adjust the pH to 4.0 , reacted at room temperature for 5 h, and the reaction product was dialyzed against pH 5.0 HCl solution (MWCO 3500 Da) at 4°C for 5 days, and freeze-dried. The reaction conditions of the blank control were the same except that EDAC / NHS was not added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com