Method for preparing fluorescence detection membrane containing dual-bandgap photonic crystals for fluorescence detection of explosives

A photonic crystal and fluorescence detection technology, applied in the field of fluorescence chemical sensors, to achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

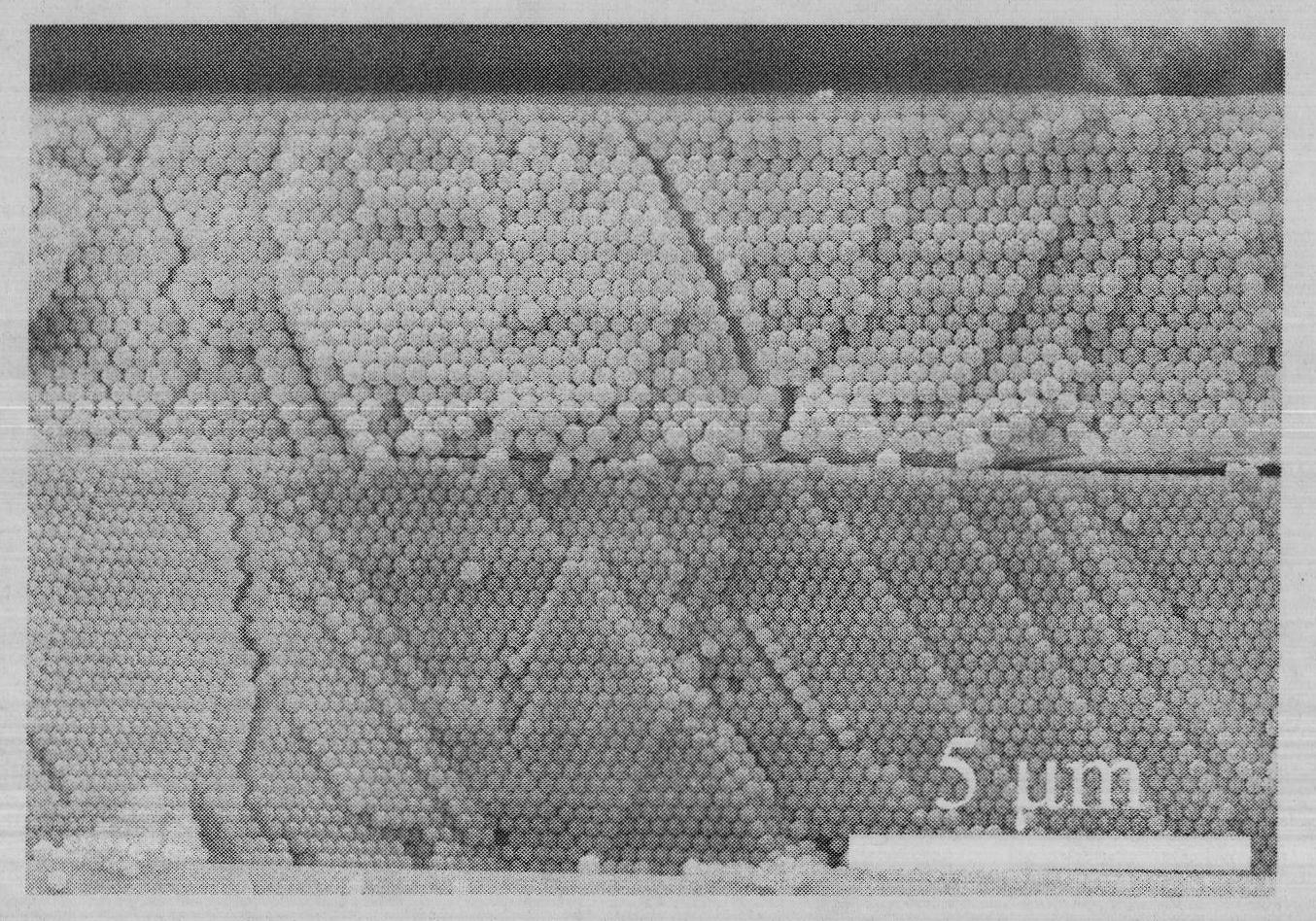

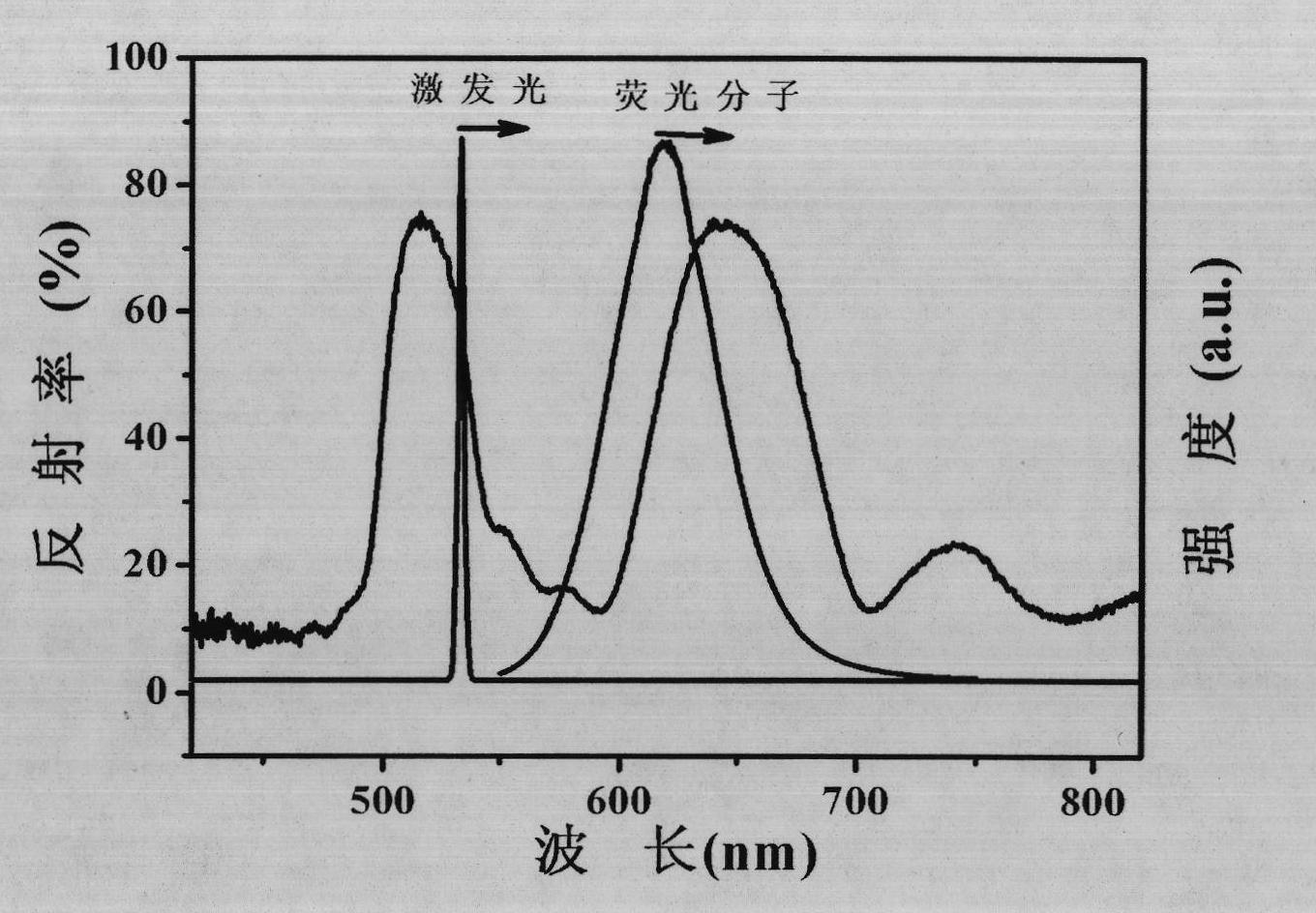

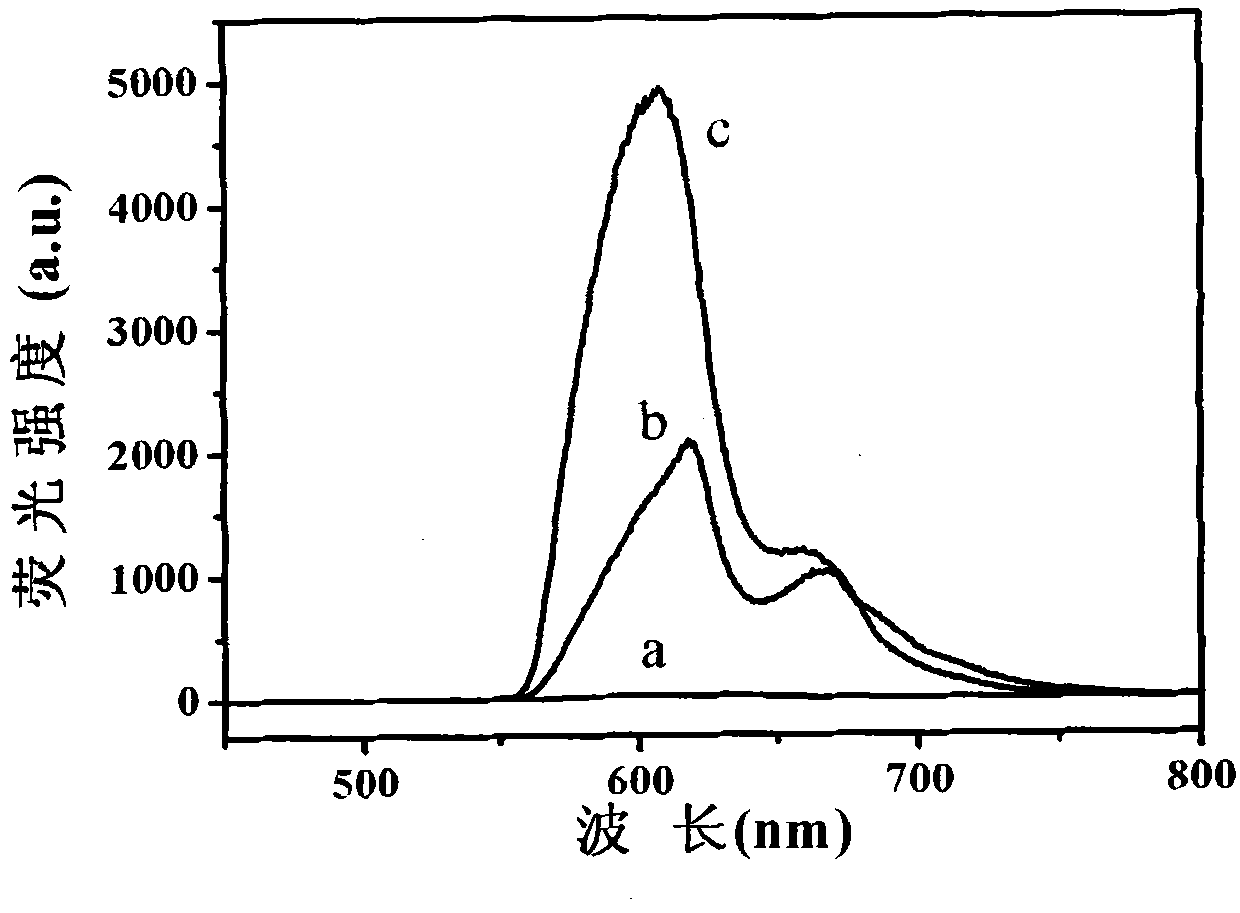

[0041] Referring to the method proposed in Patent Application No. 200710179880.3, at room temperature (25° C.), disperse monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles with a particle size of 210 nm in water to obtain an emulsion, and in the emulsion The concentration of the monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particle is 30wt%, then the emulsion of the obtained monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particle is used as spray Ink printing ink is packed in the ink box that conventional inkjet printer is used, then prints glass substrate through printer by usual method, after printing film is dried, then the monodisperse poly(styrene-methacrylic acid) that particle diameter is 270nm The emulsion (the concentration of monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particle in the emulsion is 30wt%) of the latex particle of methyl ester-acrylic acid) is packed in the ink cartrid...

Embodiment 2

[0044] At room temperature (25°C), the fluorescent molecule N,N'-bis(a-naphthyl)-N,N'-diphenyl-4,4'-binaphthylamine was dispersed into a single particle with a particle size of 180nm Disperse the emulsion of poly(styrene-methyl methacrylate-acrylic acid) latex particles to obtain a mixed solution, and the fluorescent molecule N,N'-bis(a-naphthyl)-N,N'-diphenyl in the mixed solution - The concentration of 4,4'-binaphthylamine is 10 -4 mol / L, the concentration of monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particle is 30wt%; Reference patent application number: the method proposed in 200710179880.3, the mixed solution is packed in the conventional jet printing ink as ink-jet printing ink Ink cartridges used in ink printers, and then print the paper base material by the printer according to the usual method, after the printing film is dried; The base-4,4'-binaphthylamine is dispersed in the emulsion containing the monodisperse poly(styrene-methyl methacryla...

Embodiment 3

[0046] At room temperature (25°C), the fluorescent molecule 4-amino-N-phenyl-1,8-naphthalimide was dispersed together with two kinds of monodisperse polystyrene latex particles with different particle sizes of 210nm and 230nm In water, mixed solutions were obtained respectively, and the concentration of the fluorescent molecule 4-amino-N-phenyl-1,8-naphthalimide in the two mixed solutions was 10 -4 mol / L, the concentration of monodisperse polystyrene latex particle is all 15wt%, with reference to the method that the patent application number: 200710064245.0 proposes, wherein a mixed solution is packed in the container with conventional air spray gun, the spray gun is aimed at The selected glass substrate is sprayed, and the coating film is dried; then another mixed solution is placed in a container with a conventional air spray gun, and then the spray gun is aimed at the above-mentioned monodisperse latex particle polystyrene surface that has been sprayed. The glass substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com