Technology and process for preparing biochemical humic acid by using kitchen waste

A biochemical humic acid and kitchen waste technology is applied in the field of resource treatment of kitchen waste, which achieves the effects of short time consumption, time saving, energy consumption and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Produce biochemical humic acid of the present invention as follows:

[0035] 1) Pretreatment and sieving: sieving the kitchen waste to remove inorganic substances;

[0036] 2) Cultivation: the BGB high-temperature complex bacteria are expanded and cultivated according to conventional culture methods to obtain their cultures;

[0037] 3) Blending and fermentation: the BGB high-temperature composite bacterial culture is mixed with kitchen waste and agricultural organic waste (regulator) according to the stated ratio, and fermented to obtain the finished biochemical humic acid; wherein:

[0038] Kitchen waste: 120kg;

[0039] Peanut shell (adjusting material): 80kg;

[0040] BGB compound bacteria fermentation agent (1.5×10 8 cfu / g): 30g;

[0041] Fermentation time: 8 hours;

[0042] Fermentation temperature: 80°C.

Embodiment 2

[0044] Production method is with embodiment 1, and raw material ratio is as follows:

[0045] Kitchen waste: 120kg;

[0046] Adjusting material: wheat straw 40kg, peanut shell 40kg, moisture content adjusted to 55%;

[0047] BGB compound bacteria fermentation agent (2.0×10 8 cfu / g): 30g;

[0048] Fermentation time: 10 hours;

[0049] Fermentation temperature: 60°C.

Embodiment 3

[0051] Production method is with embodiment 1, and raw material ratio is as follows:

[0052] Kitchen waste: 120kg;

[0053] Adjusting material: rice husk 40kg, peanut husk 40kg, moisture content adjusted to 60%;

[0054] BGB compound bacteria fermentation agent (2.0×10 8 cfu / g): 30g;

[0055] Fermentation time: 8 hours;

[0056] Fermentation temperature: 80°C.

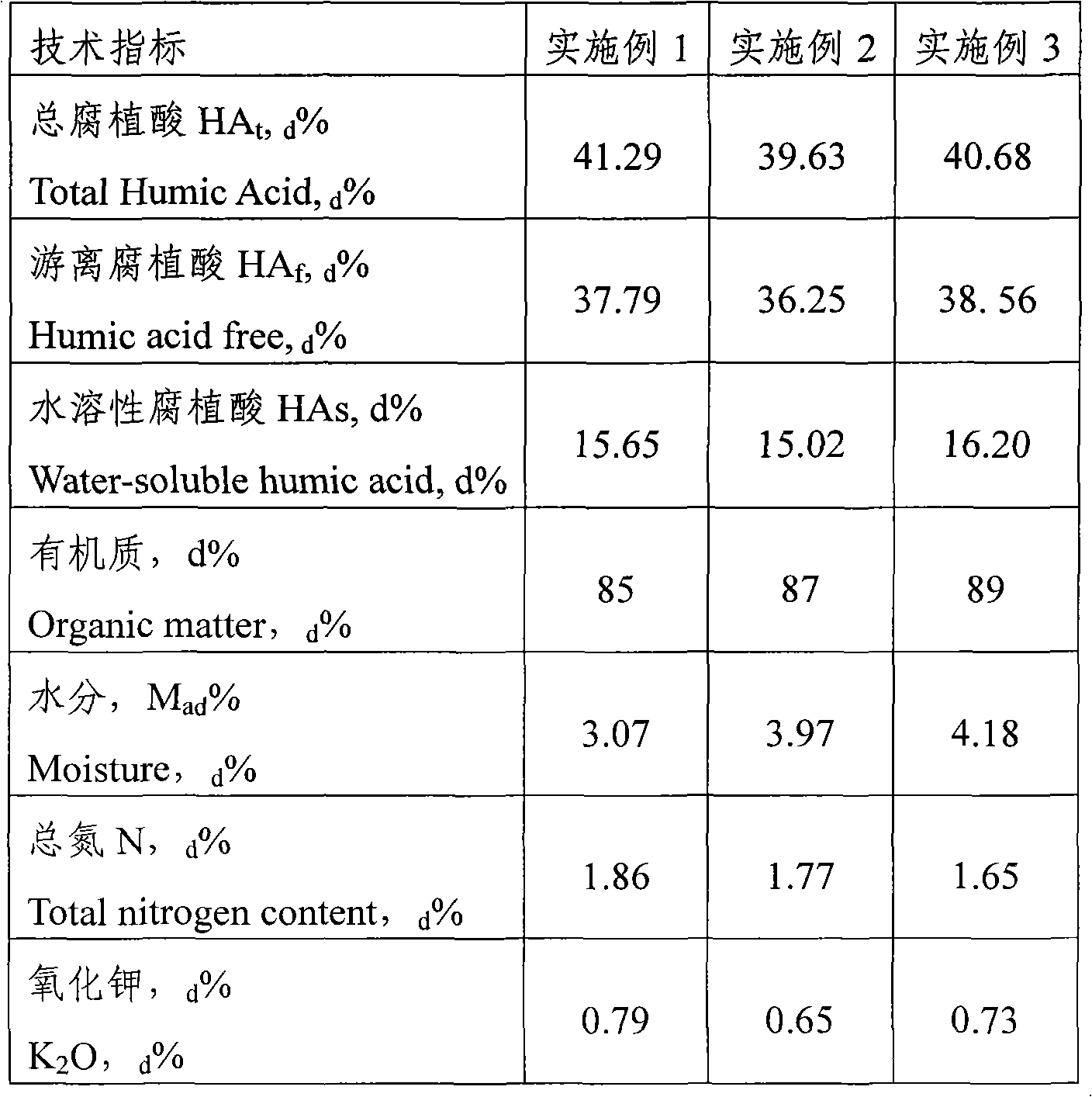

[0057] The technical index detection of the BHA that above-mentioned embodiment obtains is shown in the following table:

[0058] Table 2

[0059]

[0060] (The testing standard for total humic acid and free humic acid is GB / P11957-2001, and the testing standard for water-soluble humic acid is HG / P3278-87.)

[0061] It can be seen from the above examples that the conversion rate of organic matter after the kitchen waste is treated by the technical scheme of the present invention is high, which can reach more than 90%. At the same time, the prepared biochemical humic acid is rich in nutrients, not only contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com