Trace metal element Chelation fertilizer in lignin and application thereof

A technology of trace metal elements and metal elements, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of limited chelation ability, and achieve the effect of strong chelation ability, good fertilizer efficiency and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Chelation Stability of Lignin Salts and Fe Elements

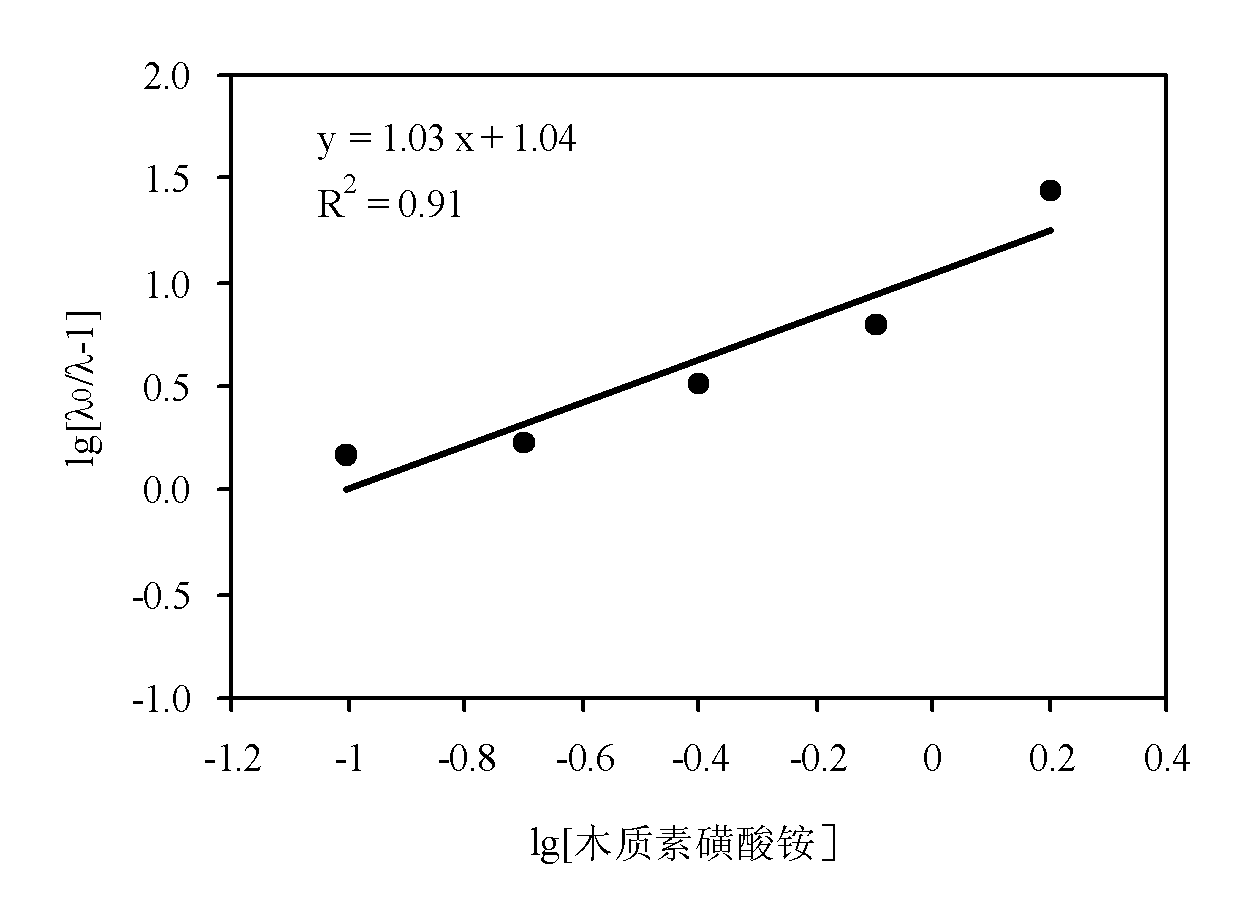

[0094] In this study, the chelation average coordination number x and the chelation equilibrium constant lgK of the lignin salt-Fe chelate were measured respectively by the ion exchange equilibrium method, and the results are listed in Table 1. The lg(λ 0 / λ-1) and lg [lignin salt] relation diagram such as figure 1 shown.

[0095] Chelation stability determination of table 1 lignin salt and FeSO

[0096]

[0097] Note: α is [M], β is [M]+[MAx], γ is [Mf]-[M], δ is [Mf]-([M]+[MAx])

[0098] Depend on figure 1 It can be seen that lignin salt and FeSO 4 The coordination number x of Fe is 1.03, and its stability constant lgK is equal to 1.04.

[0099] h 2 o 2 Chelation Stability of Oxidized Lignin Salts with Fe Elements

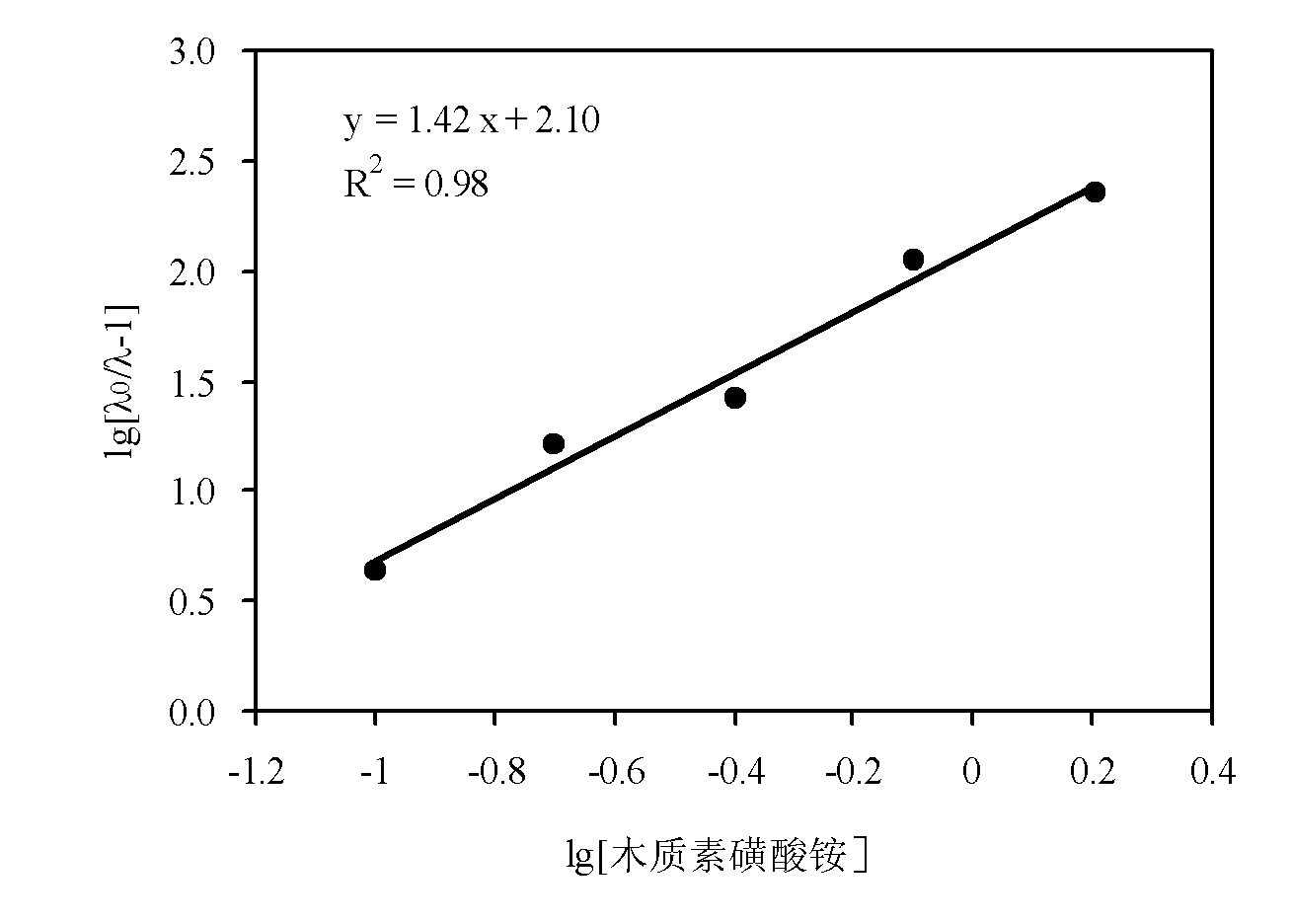

[0100] The preparation reaction condition of oxidized lignin salt is H 2 o 2 Adding amount 2.5%; FeSO 4 :H 2 o 2 =1:20 (mol ratio), reaction temperature 40°C, reaction time 30min. Deter...

Embodiment 2

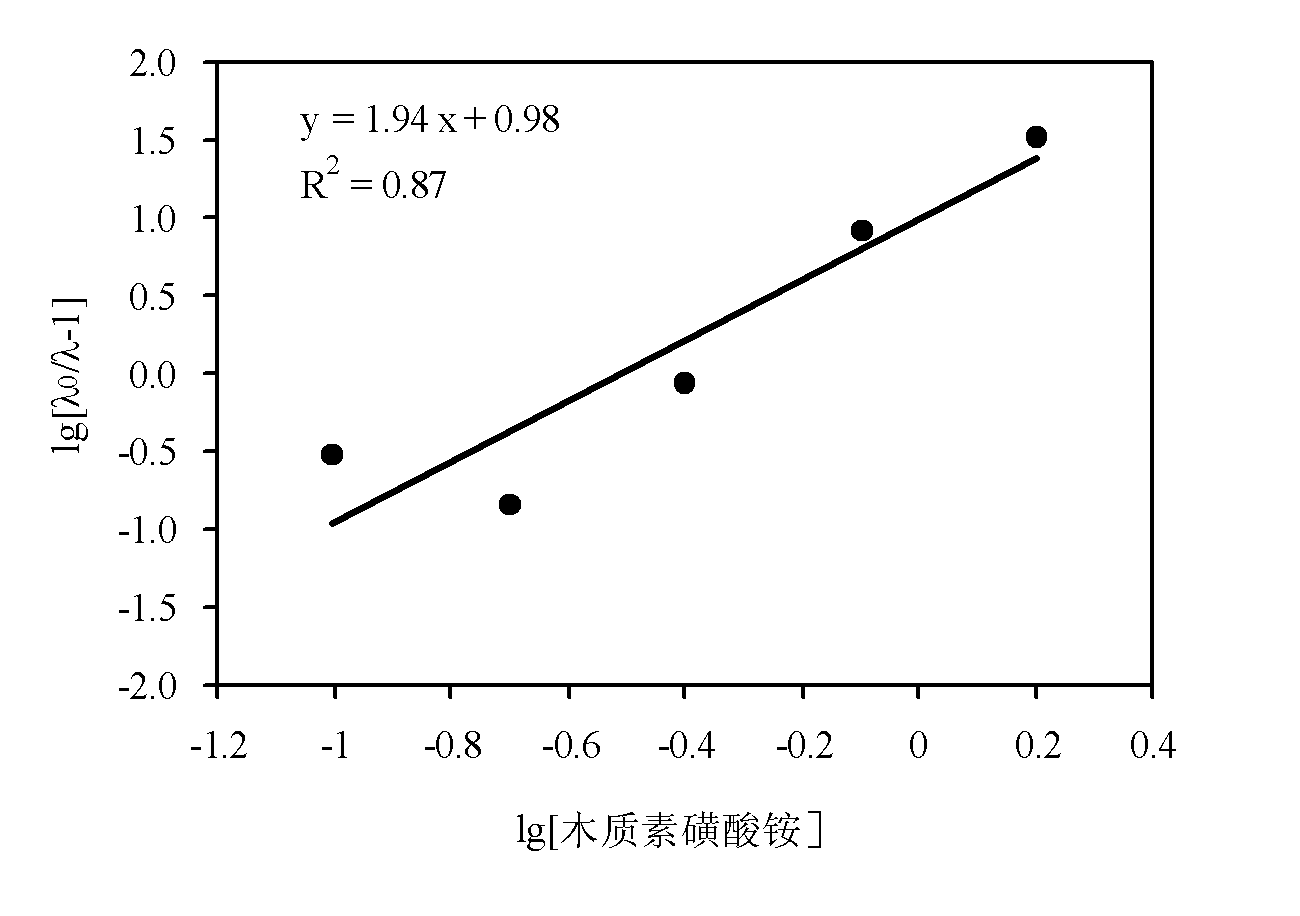

[0111] Chelation Stability of Lignin Salt and Zn

[0112] Also measure the chelation average coordination number x and the chelation equilibrium constant lgk of lignin salt-Zn chelate with ion exchange equilibrium method respectively, the results are listed in table 3, lignin salt-Zn 2+ Chelate lg(λ 0 / λ-1) and lg [lignin salt] relation diagram such as image 3 Shown:

[0113] Depend on image 3 It can be seen that the average coordination number of the lignin salt-Zn chelate is 1.94, and the chelation stability constant is 0.98. Its coordination number is higher than lignin salt-Fe chelate, but its stability constant is lower.

[0114] Chelation Stability of H2O2 Oxidized Lignin Salt and Zn

[0115] h 2 o 2 The preparation reaction condition of oxidized lignin salt is: H 2 o 2 Adding amount 2.5%, FeSO 4 The amount added is based on FeSO 4 :H 2 o 2 =1:20 (mol ratio) is determined, the reaction temperature is 40° C., and the reaction time is 30 minutes. Determinatio...

Embodiment 3

[0121] This study mainly investigates the excess FeSO 4 In the presence of conditions, H 2 o 2 Effects of dosage, reaction temperature and reaction time on the chelation of lignin ammonium salt and Fe element. FeSO in the reaction system 4 The mass ratio to lignin ammonium salt is 2:3, H 2 o 2 The dosages (based on lignin ammonium salt) are 0%, 2.5%, 5% and 10% respectively; the reaction times are 10min, 30min and 120min respectively; the reaction temperatures are 20°C, 40°C and 60°C respectively. By comparing the chelation rate of Fe element in the product under different reaction conditions, it is determined that lignin ammonium salt and FeSO 4 Process conditions for chelation reactions. in different H 2 o 2 The chelation rate of iron in the chelated product is shown in Table 5 under the dosage, different reaction temperatures and different reaction times.

[0122] Table 5 Fe under different process conditions 2+ Chelation rate, %

[0123]

[0124] h 2 o 2 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chelation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com