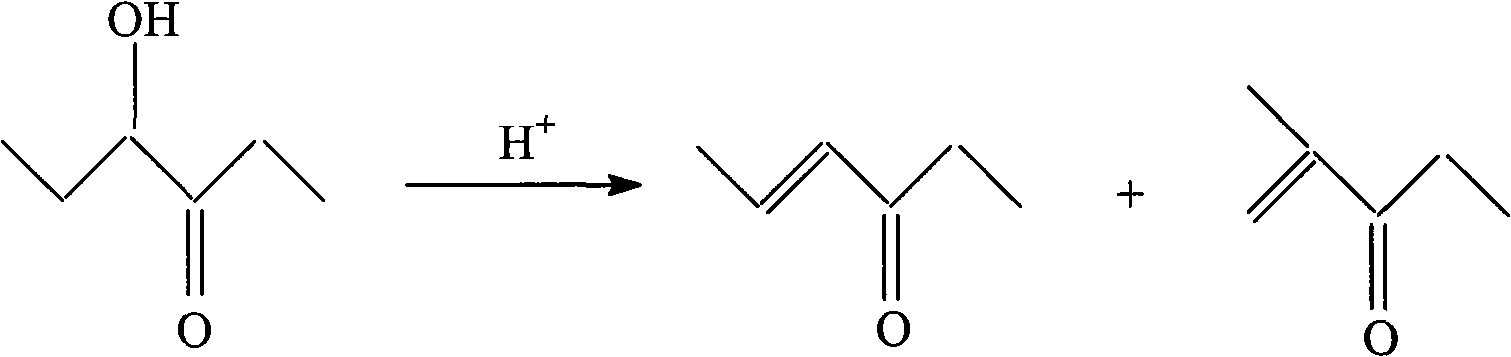

Method for catalyzing and dehydrating 4-hydroxy-3-hexanone

A technology for catalytic dehydration and hexanone, applied in chemical instruments and methods, molecular sieve catalysts, carbon-based compound preparation, etc., can solve the problems of low space velocity, poor catalyst activity, high reaction temperature, etc., and achieve reduced deep reaction and stable activity Sexual improvement, sodium content reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

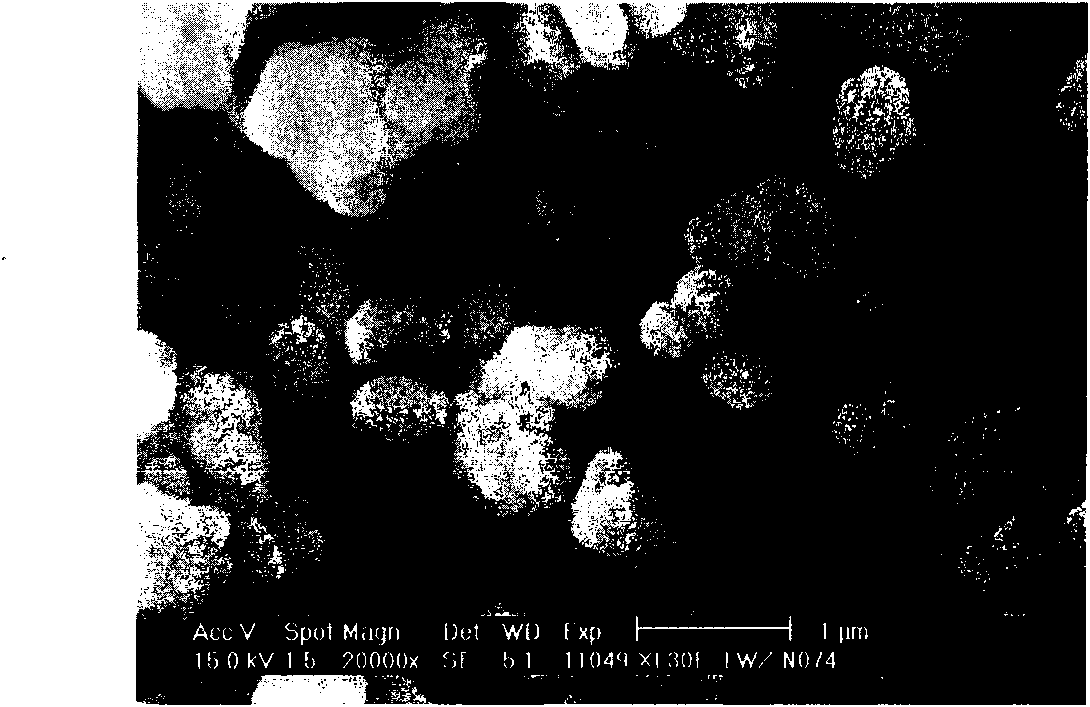

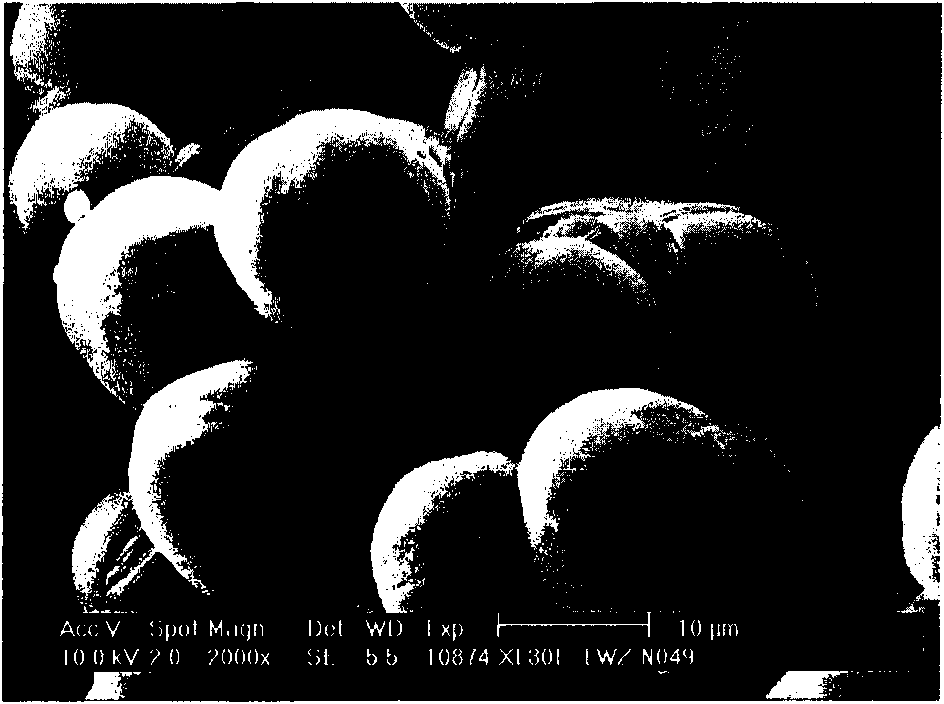

[0017] 40% silica sol, sodium metaaluminate, tetrapropylammonium bromide (TPABr), sodium chloride, sodium hydroxide and water, SiO in molar ratio 2 :Al 2 o 3 :Cl - :OH - :TPABr:H 2 O=1: 0.013: 0.68: 0.15: 0.4: 51, mixed, stirred for 20 minutes, put into a reaction kettle, and crystallized dynamically at 170° C. (200 rpm) for 3 days. The crystallized product was rapidly cooled, filtered, washed with water until the pH value was 8, and dried at 120°C for 12 hours to obtain NaZSM-5 zeolite raw powder with an average grain diameter of 0.5 microns.

Embodiment 2

[0019] The raw NaZSM-5 zeolite powder synthesized in [Example 1] was treated with 0.3 mol / L hydrochloric acid at 80°C for 4 hours for 3 consecutive times to obtain HZSM-5, which was dried at 120°C for 12 hours and calcined at 550°C for 5 hours.

Embodiment 3

[0021] According to the steps and conditions of [Example 1], only SiO in the synthetic formula 2 : Al 2 o 3 =0.025, the templating agent is 1,6-hexamethylenediamine, the crystallization temperature is 200°C for 5 days, and 1.0 mol / L citric acid is exchanged at 70°C for 5 hours for 4 consecutive times. The average crystal grain diameter of the synthesized HZSM-5 zeolite raw powder is 1 micron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com