Preparation method of blocky porous carbon with high specific surface area

A high specific surface area, porous carbon technology, applied in the field of preparing high specific surface bulk porous carbon materials, can solve the problems of high cost of supercritical drying, difficult industrialization, complicated process, etc., and achieves high mechanical strength, smooth surface, and preparation method. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

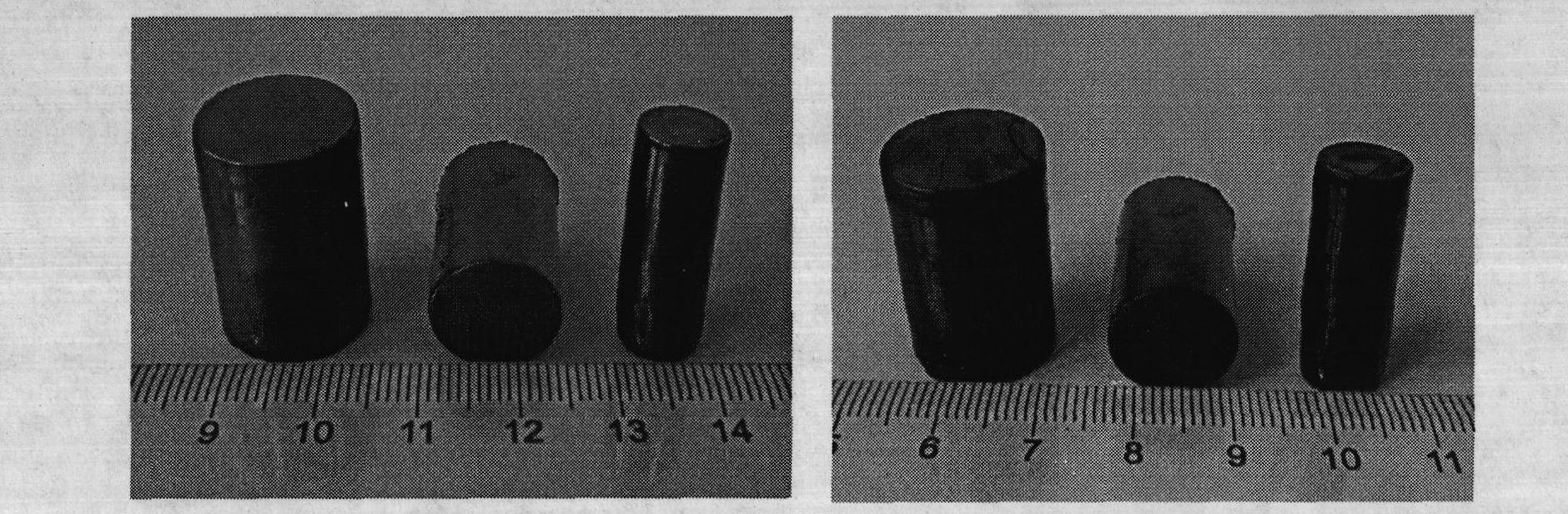

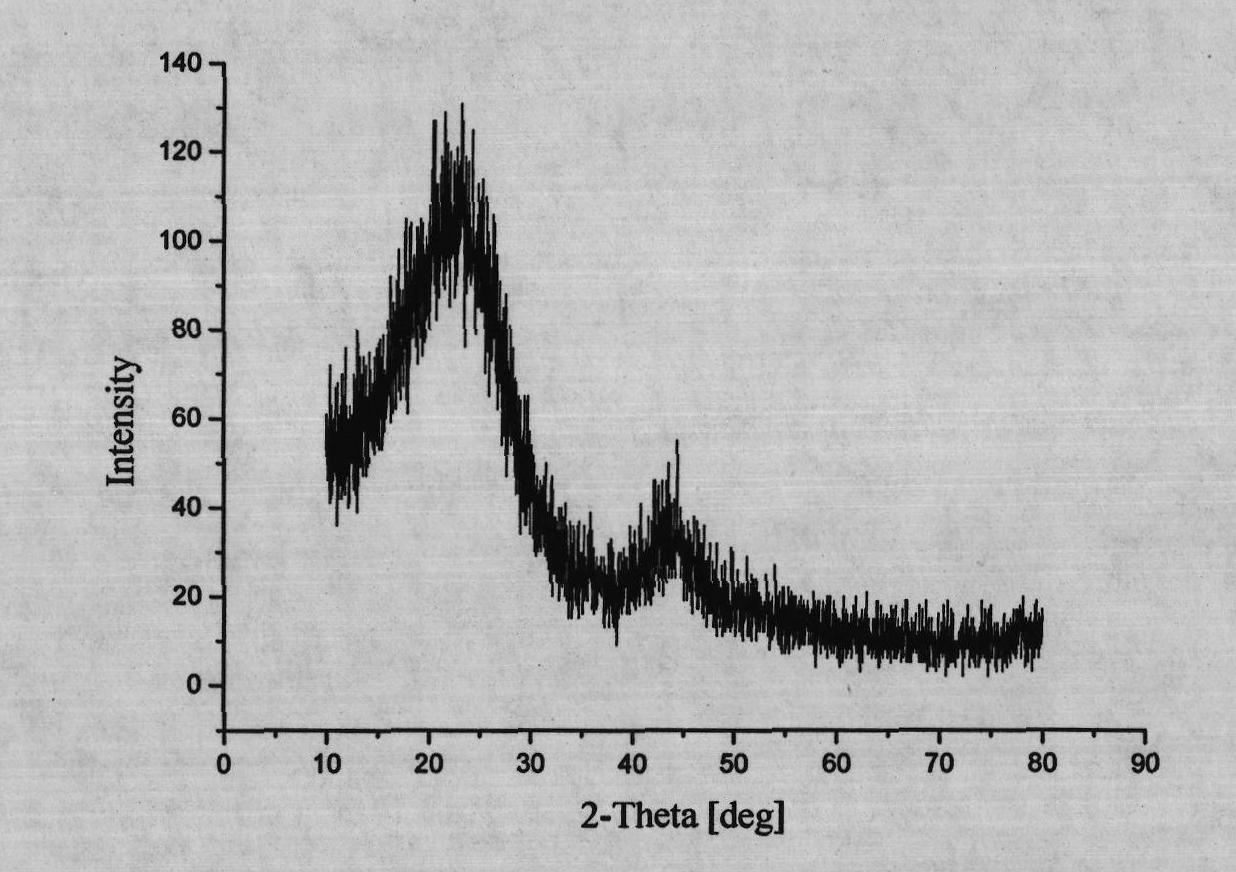

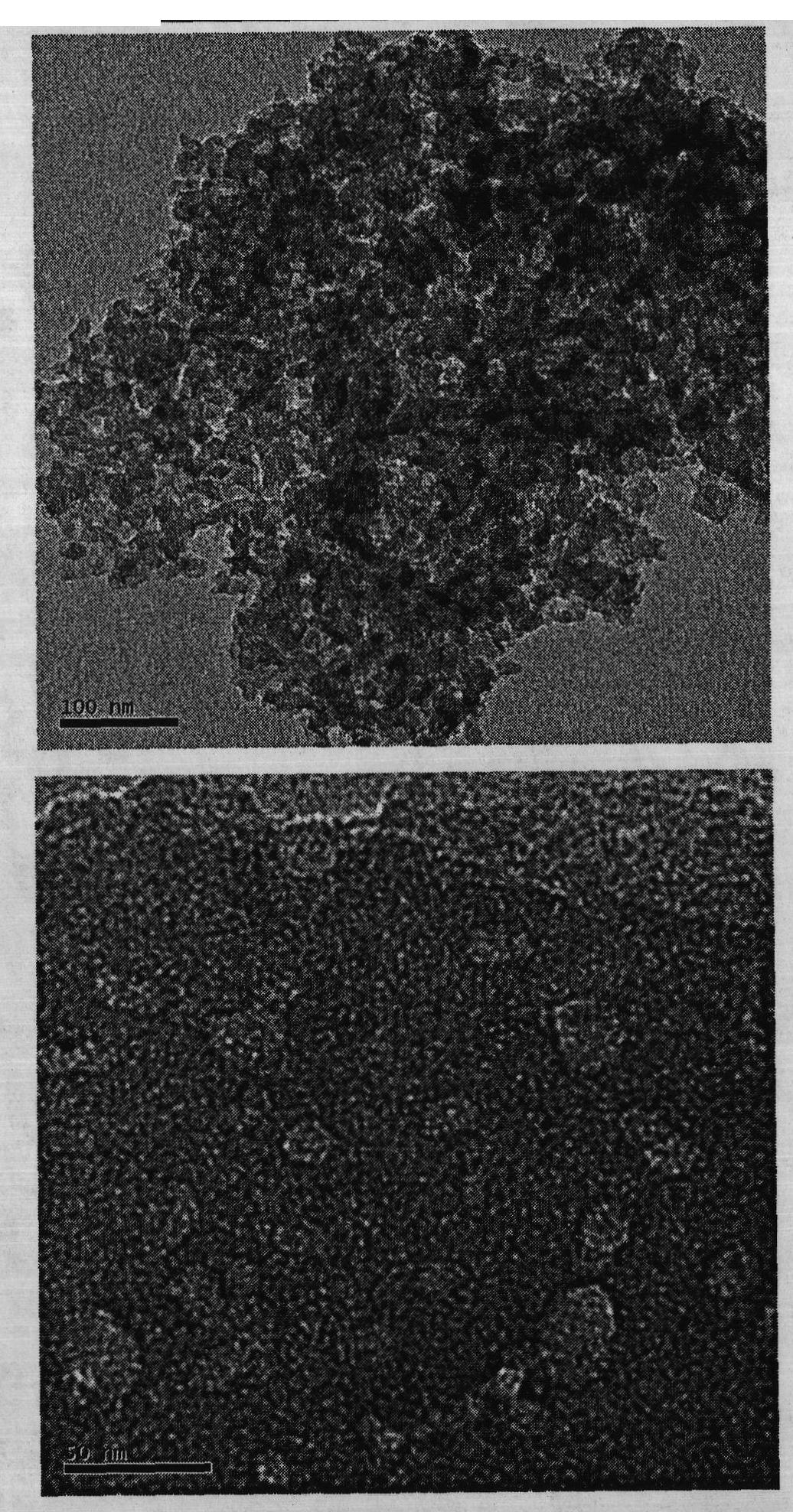

Embodiment 1

[0015] Mix phloroglucinol (R): sucrose (S): water (W): hydrochloric acid (HCl; 1M) = 2g: 4g: 10g: 1ml of phloroglucinol and glucose, add deionized water, at 50°C Stir to fully dissolve, then add hydrochloric acid, stir and mix evenly at 50°C, place in a stainless steel pressure-resistant reactor lined with polytetrafluoroethylene, put it in an oven for hydrothermal reaction, and form block hydrothermal charcoal. The obtained material is rinsed with water and ethanol, dried, and then carbonized at 700° C. under the protection of an inert atmosphere to obtain a porous carbon material with a high specific surface area. Nitrogen adsorption test results show that its specific surface area is 400m 2 / g, the pore volume is 0.17cm 3 / g.

Embodiment 2

[0017] Mix resorcinol and glucose according to resorcinol (R): sucrose (S): water (W): citric acid (CA) = 2g: 4g: 10g: 1g, add deionized water, at 50°C Stir to fully dissolve, then add citric acid, stir and mix evenly at 50°C, place in a stainless steel pressure-resistant reactor lined with polytetrafluoroethylene, put it in an oven for hydrothermal reaction, and form block hydrothermal charcoal. The obtained material is rinsed with water and ethanol, dried, and then carbonized at 700° C. under the protection of an inert atmosphere to obtain a porous carbon material with a high specific surface area. Nitrogen adsorption test results show that its specific surface area is 410m 2 / g, the pore volume is 0.2cm 3 / g.

Embodiment 3

[0019] According to phenol (R): glucose (G): water (W): sodium sulfate = 6g: 4g: 10g: 1g, mix phenol and glucose, add deionized water, stir at 50°C to fully dissolve, then add sodium sulfate, Stir and mix evenly at 50°C, place in a stainless steel pressure-resistant reaction kettle lined with polytetrafluoroethylene, put it in an oven for hydrothermal reaction, and form block hydrothermal charcoal. The obtained material is rinsed with water and ethanol, dried, and then carbonized at 900° C. under the protection of an inert atmosphere to obtain a porous carbon material with a high specific surface area. Nitrogen adsorption test results show that its specific surface area is 700m 2 / g, the pore volume is 0.83cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com