Rhamnolipid auxin

A technology of plant auxin and rhamnolipid, which is applied in the field of rhamnolipid plant auxin, can solve the problems of inability to regulate plant growth, uneven distribution of nutrient elements, and hindered plant growth, so as to achieve absorption and utilization, environmental protection and pollution-free , promote leaf absorption, prolong the effect of attachment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

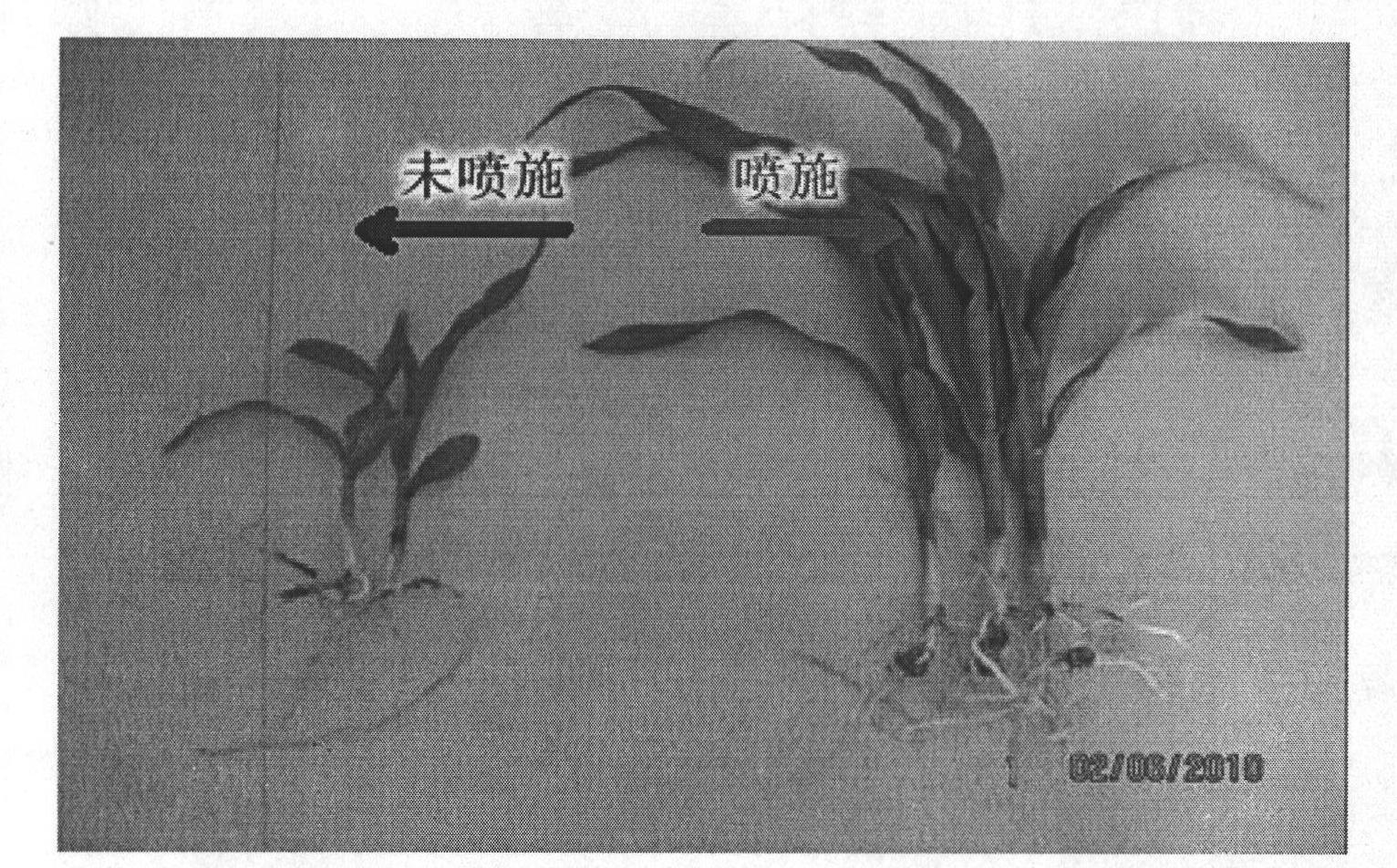

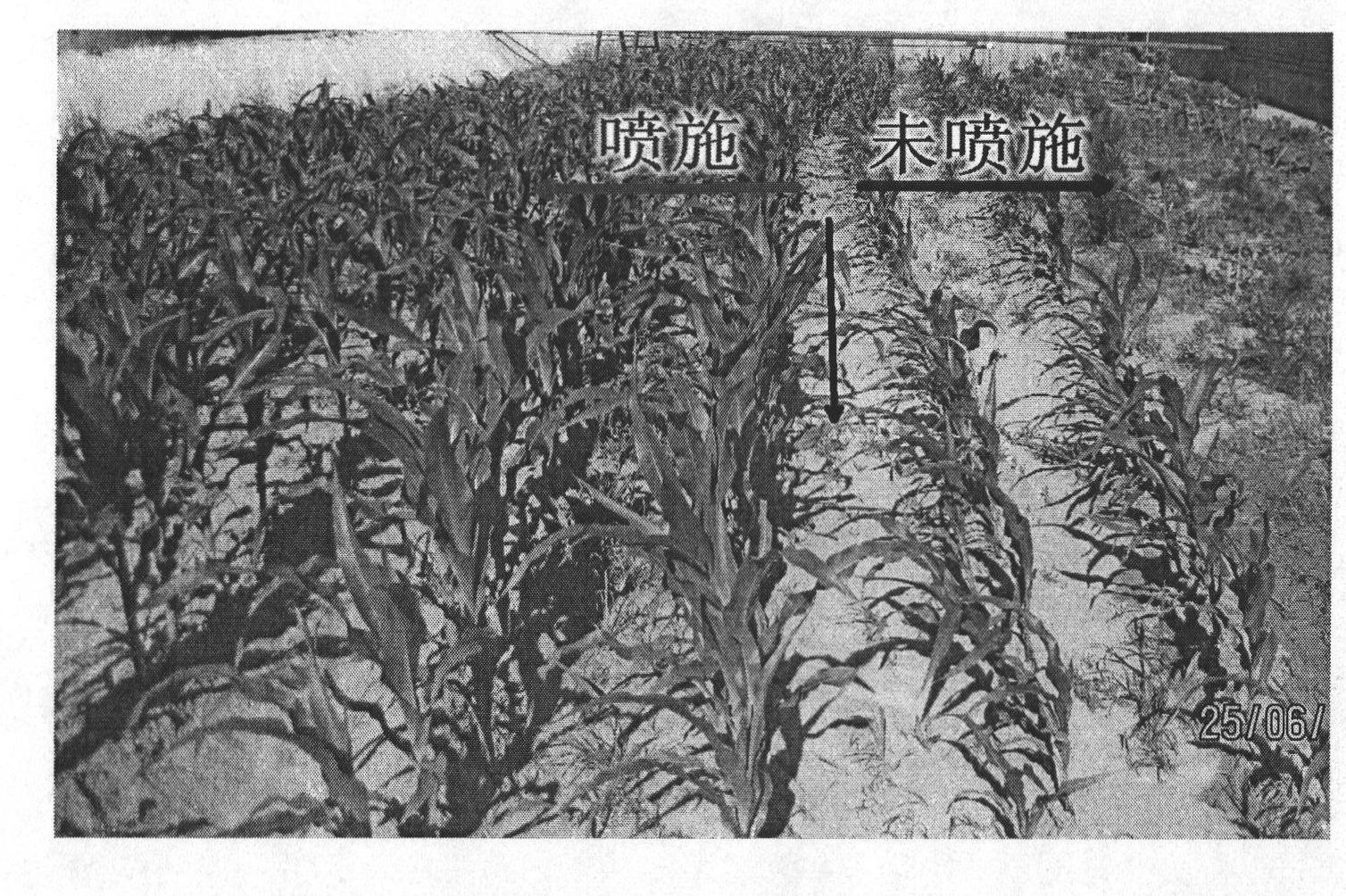

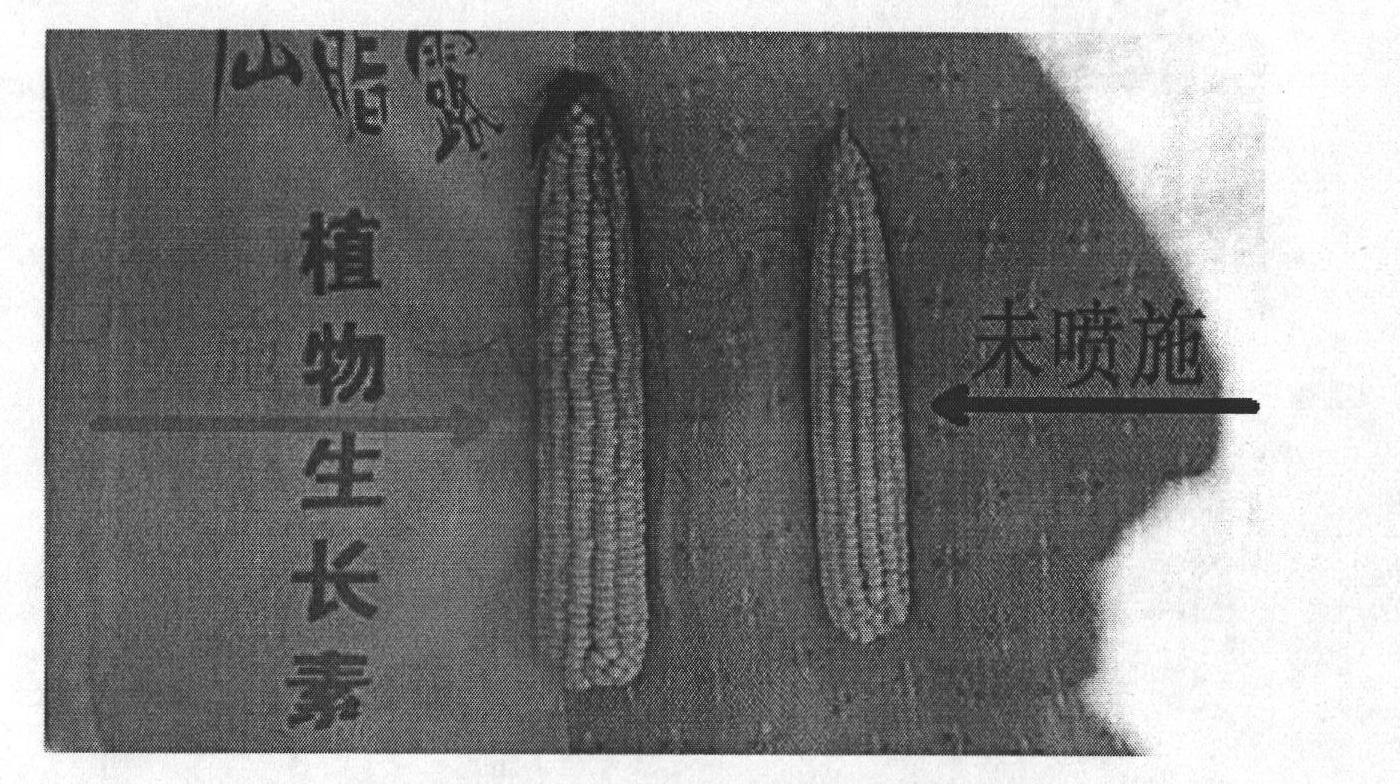

[0027] First, weigh 4% of rhamnolipid, 20% of urea, 25% of potassium dihydrogen phosphate, 1% of ammonium molybdate, 0.9% of borax, 2% of magnesium sulfate, 0.5% of manganese sulfate, 2% of zinc sulfate and the rest by weight percentage A certain amount of water is added to a uniform stirring tank, stirred at 60° C. for half an hour, and the prepared rhamnolipid auxin is used for corn crops after mixing evenly. Application of the corn of the present invention can promote the growth of corn root system. figure 1 ; for robust maize plants see figure 2 ; large ears of corn, plump, high yield image 3 .

example 2

[0029] First, weigh 3% of rhamnolipid, 12% of urea, 15% of potassium dihydrogen phosphate, 0.2% of ammonium molybdate, 0.5% of borax, 1% of magnesium sulfate, 1% of manganese sulfate, 2% of zinc sulfate and the rest by weight percentage. Add a certain amount of water into a uniform stirring tank, stir at 60° C. for half an hour, and after mixing evenly, let the prepared rhamnolipid auxin be used for potato crops. Rhamnolipid auxin can effectively inhibit potato blight and resist premature aging. Potatoes are well-proportioned. Figure 4 .

example 3

[0031] First weigh 2.5% rhamnolipid, 10% urea, 20% potassium dihydrogen phosphate, 0.8% ammonium molybdate, 0.4% borax, 1% magnesium sulfate, 1% manganese sulfate, 2% zinc sulfate and the rest by weight percentage The amount of water is added into a uniform stirring tank, stirred at 60° C. for half an hour, and the prepared rhamnolipid auxin is used for soybean crops after mixing evenly. Rhamnolipid auxin effectively promotes the development of plant roots, promotes the formation of root nodules, and improves nitrogen fixation ability. Figure 5 . Seeds are plump, pods are abundant, and yield is greatly improved. See Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com