Mechanical alloying method for preparing strengthened dispersion alloy of nickel-based oxide

A technology of mechanical alloying and dispersion strengthening, which is applied in the field of preparing new nickel-based oxide dispersion strengthening alloys, and achieves the effects of easy volume fraction, significant strengthening effect, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

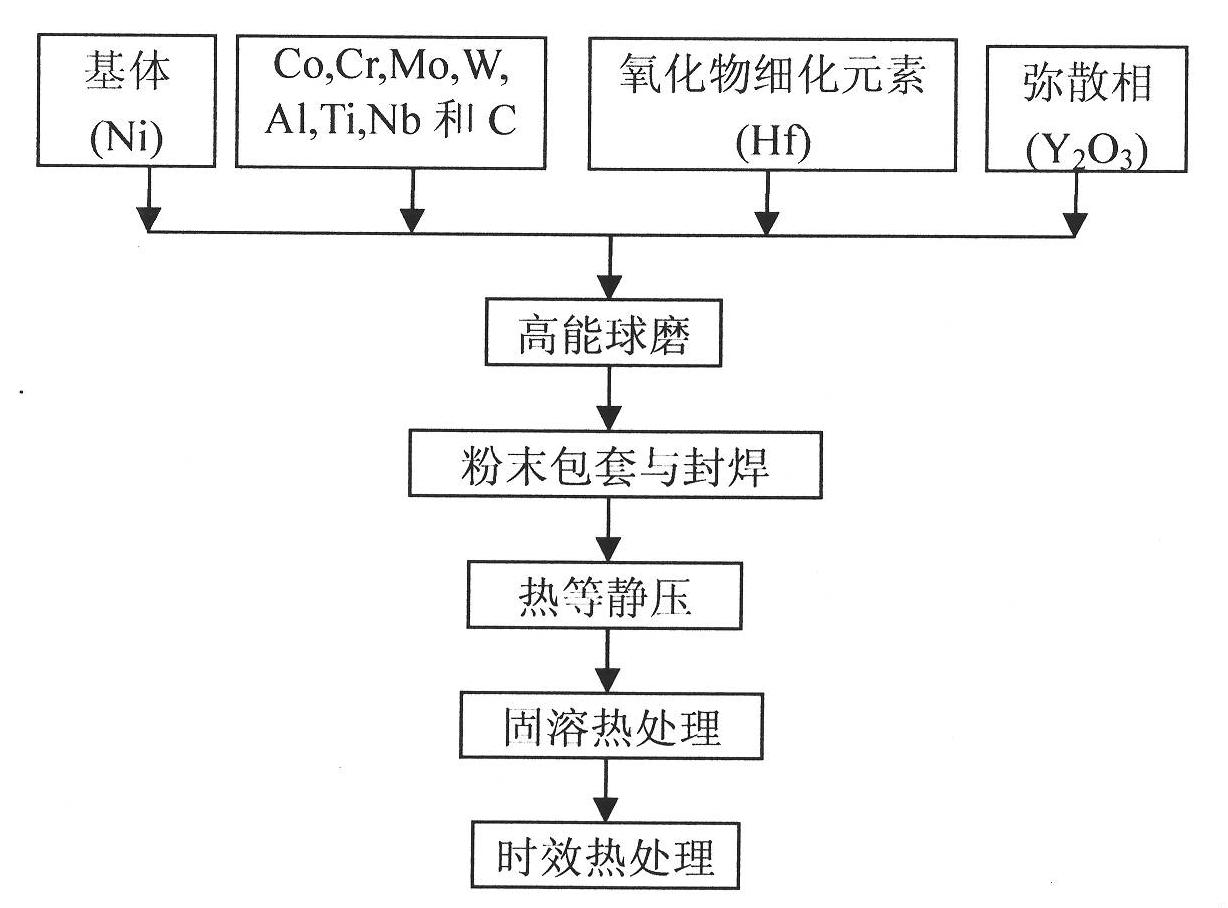

Method used

Image

Examples

Embodiment 1

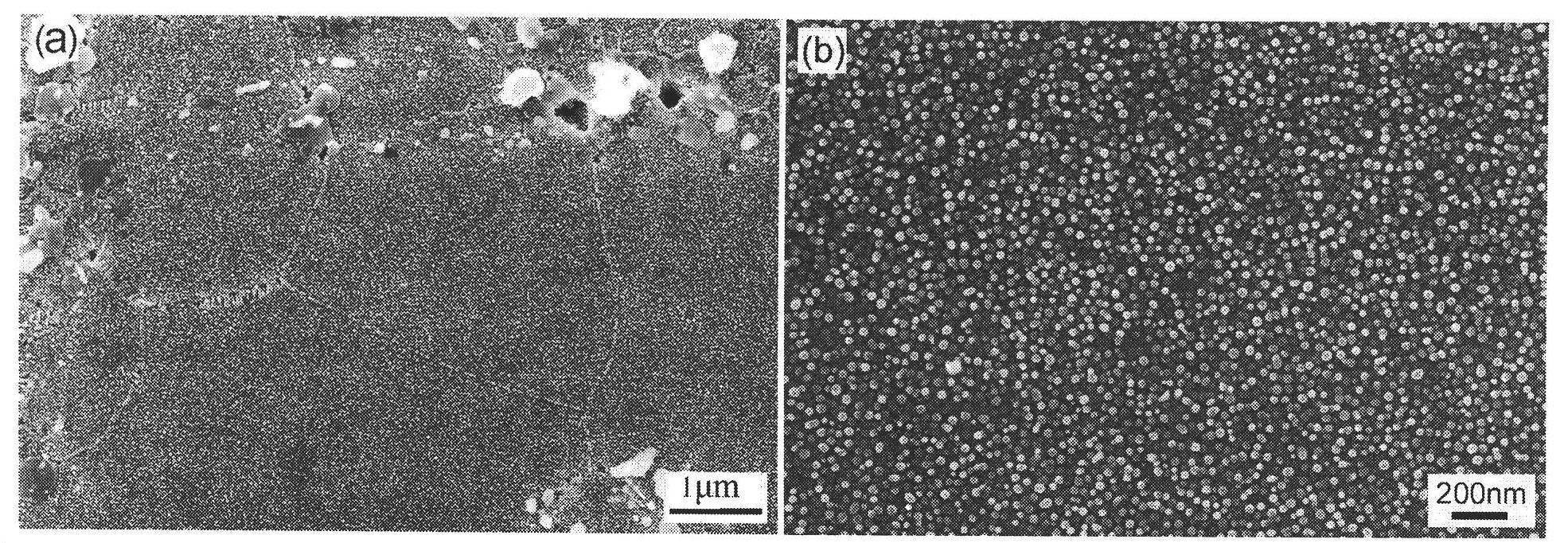

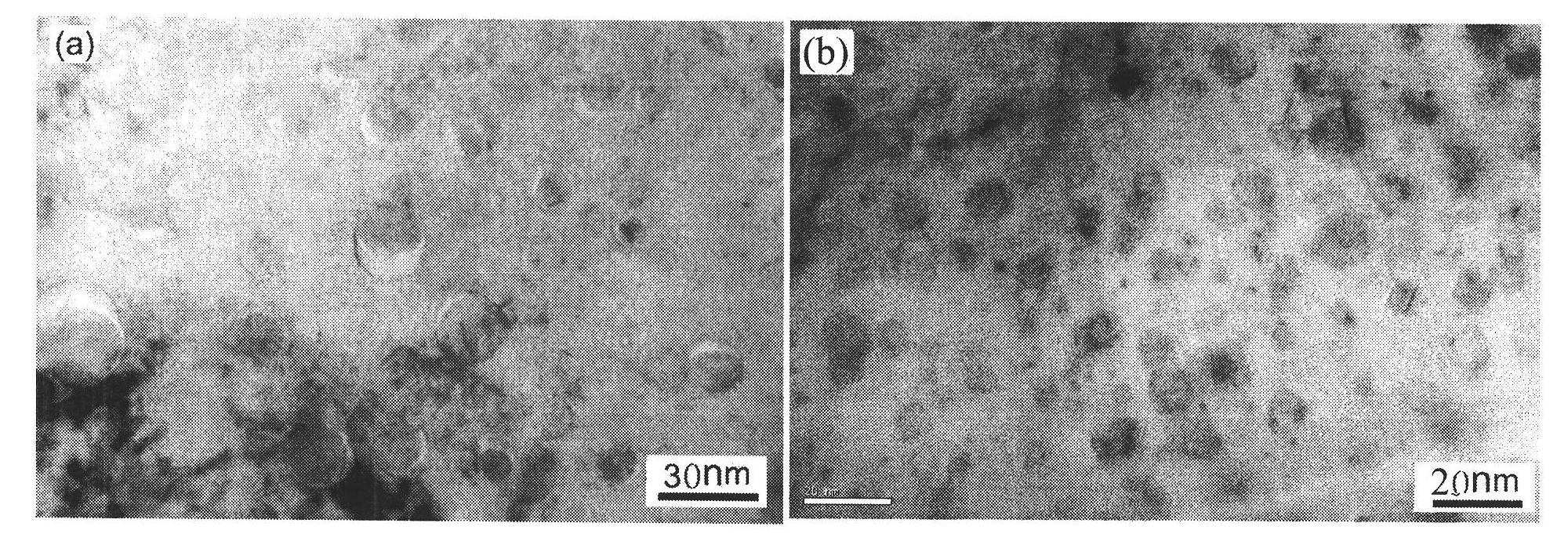

[0018] Example 1: A new nickel-based ODS alloy with 1.5% by weight of Hf added.

[0019] First, Ni-13wt%Co-15wt%Cr-4wt%Mo-4wt%W-2.2wt%Al-3.7wt%Ti-0.8wt%Nb-0.03wt%C were weighed according to the composition ratio , and then add 1% by weight of oxide particles (Y 2 o 3 ) and 1.5% by weight of oxide refining elements (Hf). Next, the element mixed powder is packaged in a glove box, using high-purity helium (99.999%) as a protective atmosphere. Y by mechanical alloying 2 o 3 The particles are evenly dispersed in the nickel matrix; at the same time, 2% by weight of stearic acid is added as a process control agent to prevent the powder from adhering to the inner wall of the ball mill during the high energy ball milling process. The rotating speed of the ball mill was 400 rpm, and the ball milling time was 48 hours. The alloy powder after high-energy ball milling is vacuum-coated with low-carbon steel, and then densified on a hot isostatic pressing device. The hot isostatic pres...

Embodiment 2

[0020] Example 2: A new nickel-based ODS alloy prepared by sub-solid solution + slow cooling and heat treatment (25° C. / min).

[0021] First, Ni-13wt%Co-15wt%Cr-4wt%Mo-4wt%W-2.2wt%Al-3.7wt%Ti-0.8wt%Nb-0.03wt%C were weighed according to the composition ratio , and then add 1% by weight of oxide particles (Y 2 o 3 ) and 1.5% by weight of oxide refining elements (Hf). Next, the element mixed powder was packaged in a glove box, using high-purity argon (99.999%) as a protective atmosphere. Y by mechanical alloying 2 o 3 The particles are uniformly dispersed in the nickel matrix; at the same time, 1% by weight of stearic acid is added as a process control agent to prevent the powder from adhering to the inner wall of the ball mill during the high-energy ball milling process. The rotating speed of the ball mill was 400 rpm, and the ball milling time was 60 hours. The alloy powder after high-energy ball milling is vacuum-coated with low-carbon steel, and then densified on a hot ...

Embodiment 3

[0022] Example 3: A new nickel-based ODS alloy prepared by solid solution + rapid cooling and heat treatment (800° C. / min).

[0023] First, Ni-13wt%Co-15wt%Cr-4wt%Mo-4wt%W-2.2wt%Al-3.7wt%Ti-0.8wt%Nb-0.03wt%C were weighed according to the composition ratio , and then add 1% by weight of oxide particles (Y 2 o 3 ) and 1.5% by weight of oxide refining elements (Hf). Next, the element mixed powder was packaged in a glove box, using high-purity argon (99.999%) as a protective atmosphere. Y by mechanical alloying 2 o 3 The particles are uniformly dispersed in the nickel matrix; meanwhile, 3% by weight of stearic acid is added as a process control agent to prevent the powder from adhering to the inner wall of the ball mill during the high energy ball milling process. The rotating speed of the ball mill was 400 rpm, and the ball milling time was 72 hours. The alloy powder after high-energy ball milling is vacuum-coated with low-carbon steel, and then densified on a hot isostatic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com