Hyperfine polyester drawn yarn and production technique thereof

A technology of ultra-fine polyester and fully drawn yarn, which is used in melt spinning, textiles and papermaking, etc., can solve the problems of poor evenness, dyeing performance and other physical properties, can not improve product grade and added value, ultra-fine fiber Difficulty in product development and other problems, to achieve excellent physical properties, improve product quality and added value, and achieve good fabric styles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further illustrate technical scheme of the present invention by specific embodiment:

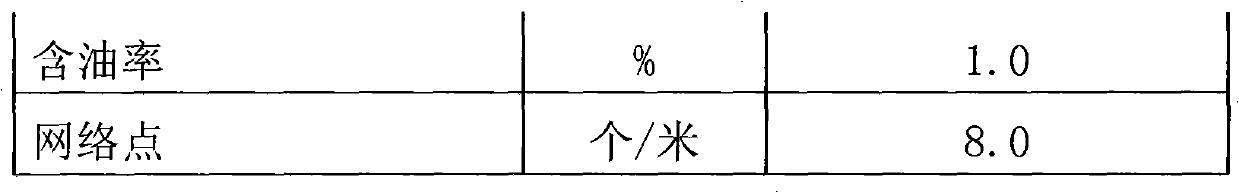

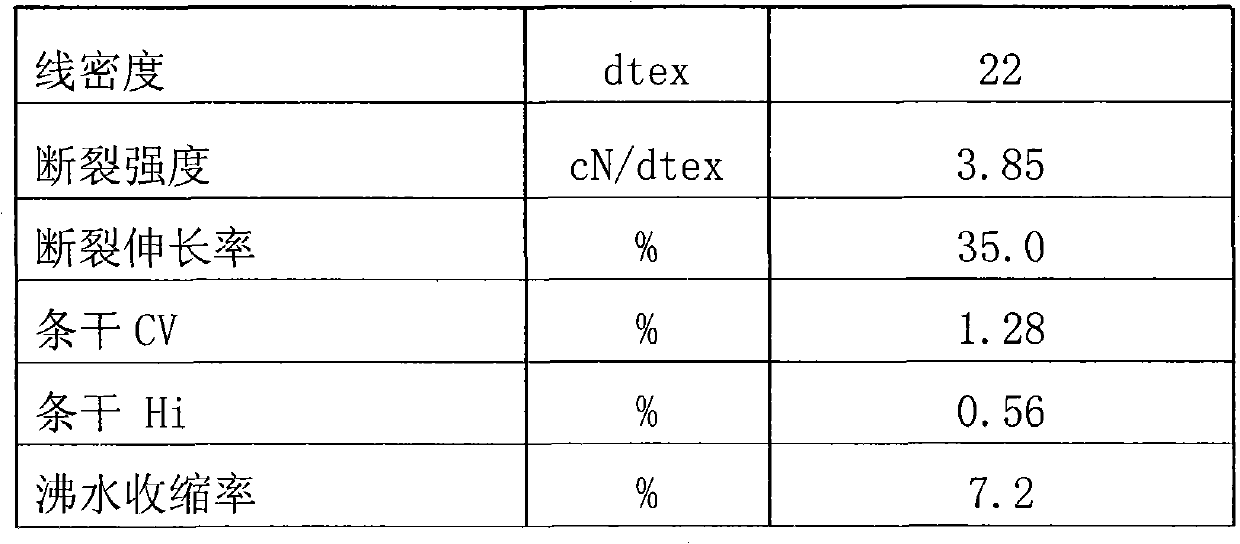

[0019] Using Barmag side blowing equipment and a modified 18-spinning position winding machine to produce 22dtex / 12F ultra-fine polyester full-drawn yarn, first through the esterification reaction of purified terephthalic acid and ethylene glycol, and then After pre-condensation and final polycondensation, the polyester melt with a viscosity of 0.650 is prepared for direct spinning, and the one-step process technology of side-blown cooling, spinning and stretching is adopted. The ccm metering pump ensures the fineness of the products produced. Each spinneret with 18 spinneret holes is selected. The 18 holes of the 12 spinneret plates are divided into 12 holes and 6 holes, 6 holes and 12 holes, and 12 holes. And 6 holes, 6 holes and 12 holes, 12 holes and 6 holes, 6 holes and 12 holes, 12 holes and 6 holes, 6 holes and 12 holes, 12 holes and 6 holes, 6 holes and 12 holes, 12 holes and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com