Papermaking sludge paperboard and preparation thereof

A papermaking sludge and cardboard technology, applied in the field of papermaking, can solve problems such as increased operating costs of enterprises, no market application, land salinization, etc., to solve the problem of sludge copying, realize recycling and reuse, and increase production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation of embodiment 1 sludge cardboard

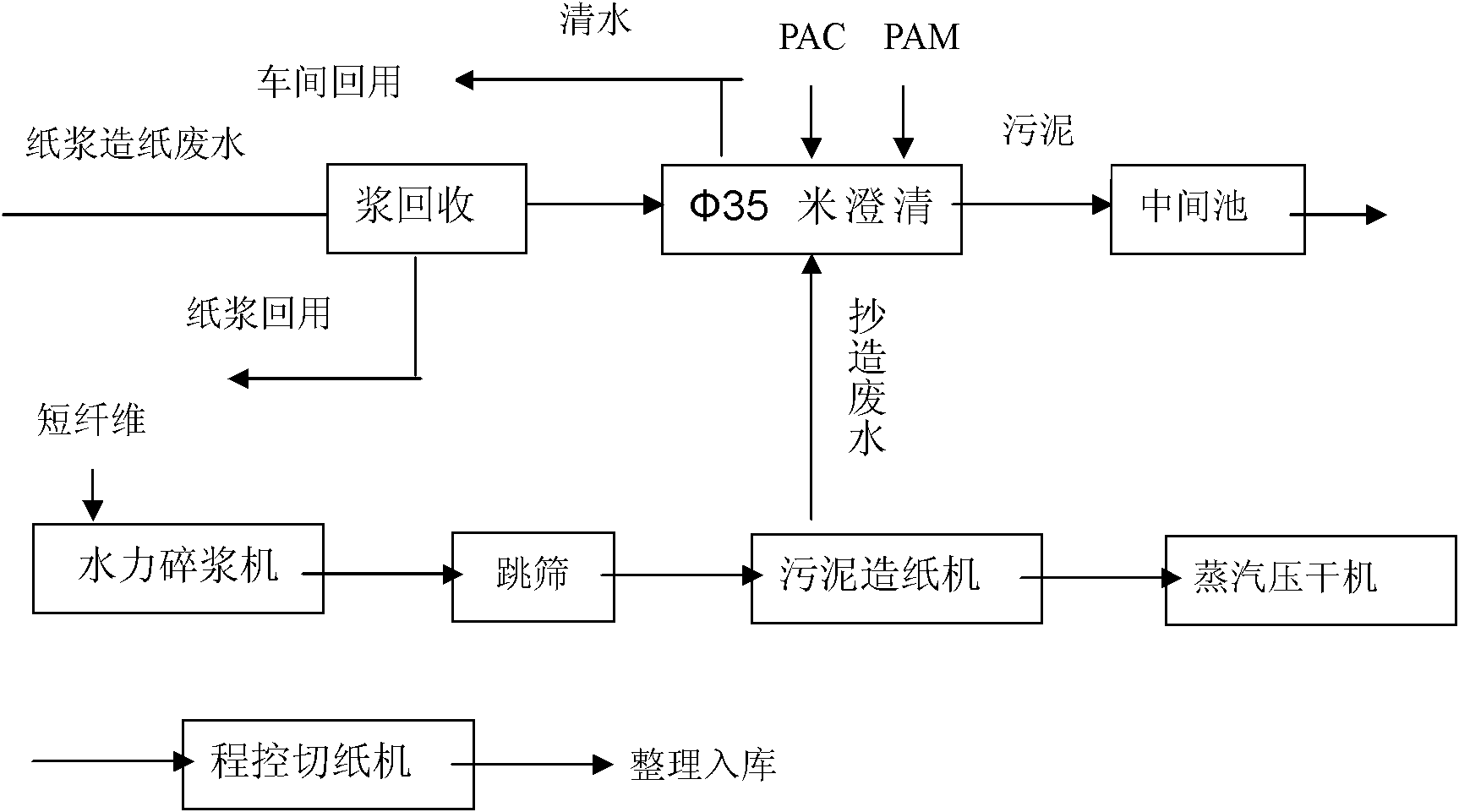

[0054] process such as figure 1 shown, including the following steps:

[0055] ①Recover the pulp fibers in the pulp and papermaking wastewater, and the remaining wastewater enters the clarification tank;

[0056] ② The SS (suspended solids) in the wastewater from the clarifier are quickly settled by PAC and PAM, and the supernatant is reused.

[0057] ③The sludge settled in the clarifier tank is pumped into the intermediate tank for storage.

[0058] ④ Fully mix the sludge in the intermediate tank with textile waste-short fiber in a hydropulper to obtain a mixture. In the mixture, the weight percentage of short fibers is 10%.

[0059] ⑤Use jumping sieve to sieve the sundries in the mixture.

[0060] ⑥ Copy the mixed material after removing sundries into wet paper.

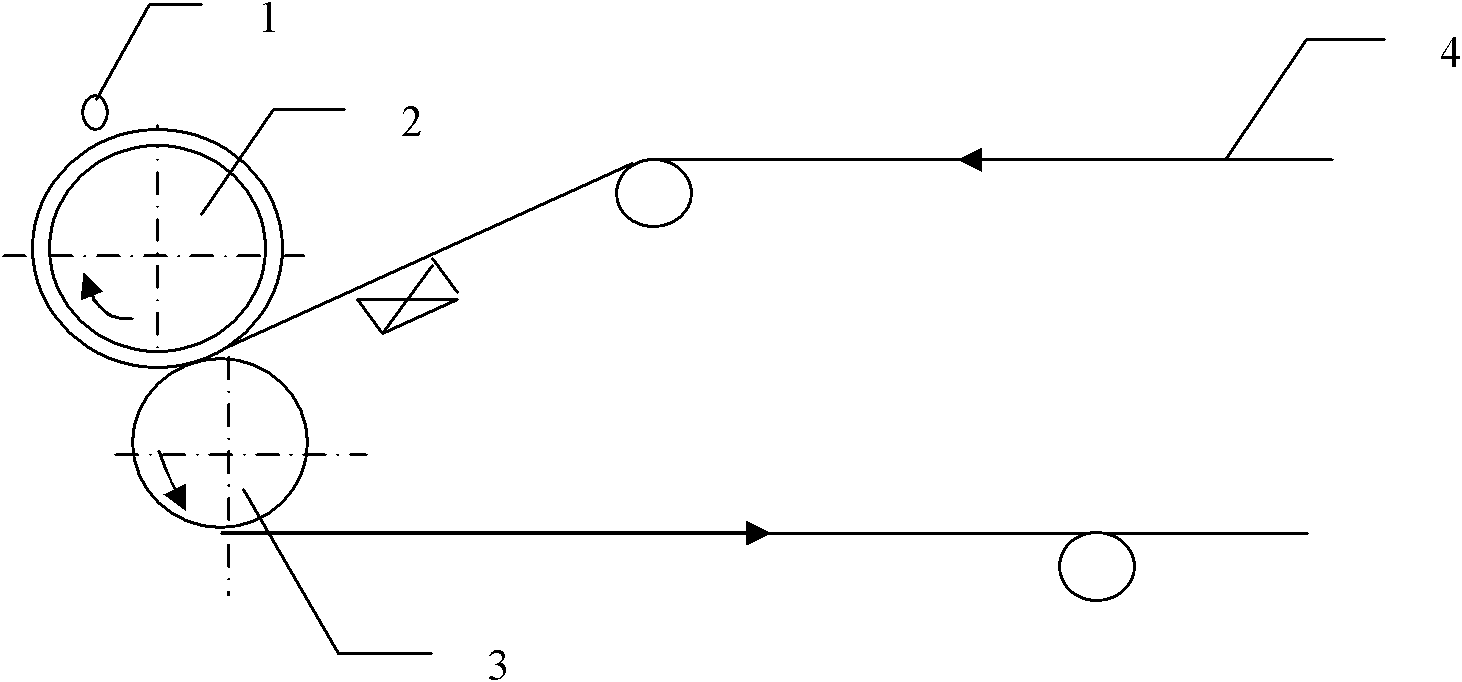

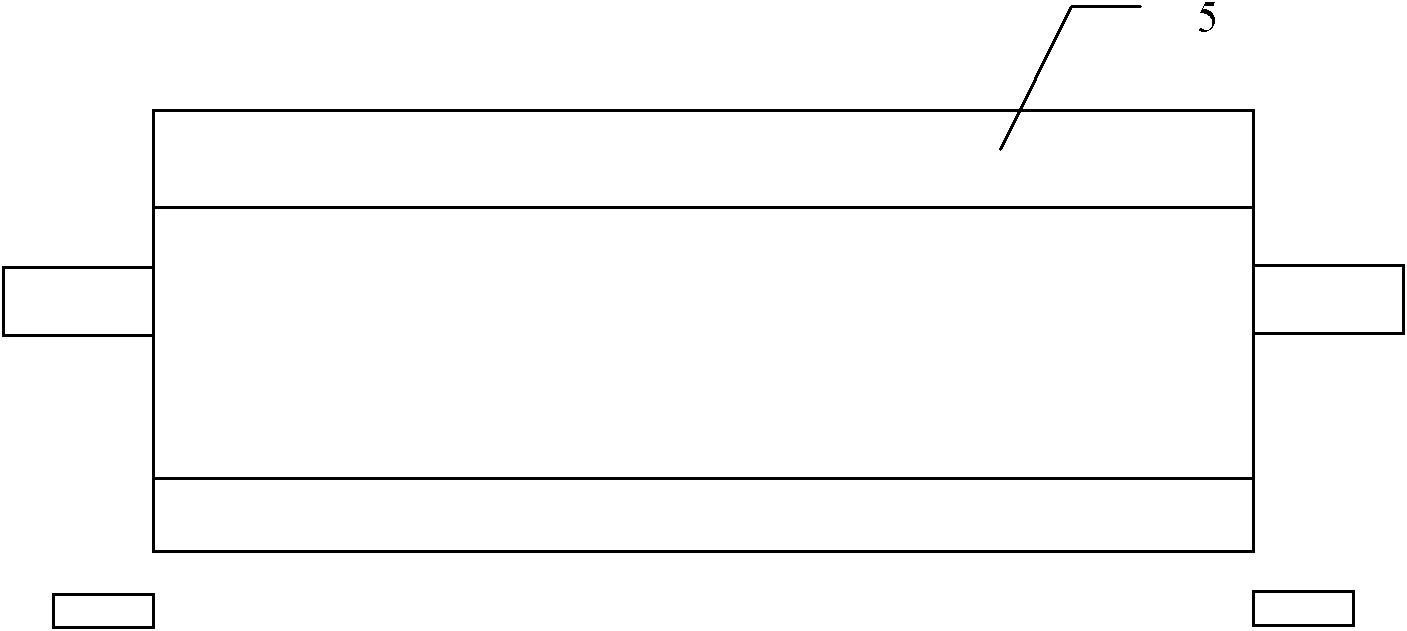

[0061] Copying process such as figure 2 with 3 As shown, the unformed sludge cardboard after papermaking is sent to the upper and lower press rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com