Plasma power supply chopper

A chopper and plasma technology, applied in the field of choppers, can solve the problems of physical structure design, circuit design and maintenance troubles of tube volume choppers, the working frequency is limited to 50Hz, and the ability to control current is low, so as to achieve anti-corrosion Good secondary breakdown performance, low driving power, strong current control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically described through embodiments below in conjunction with the accompanying drawings.

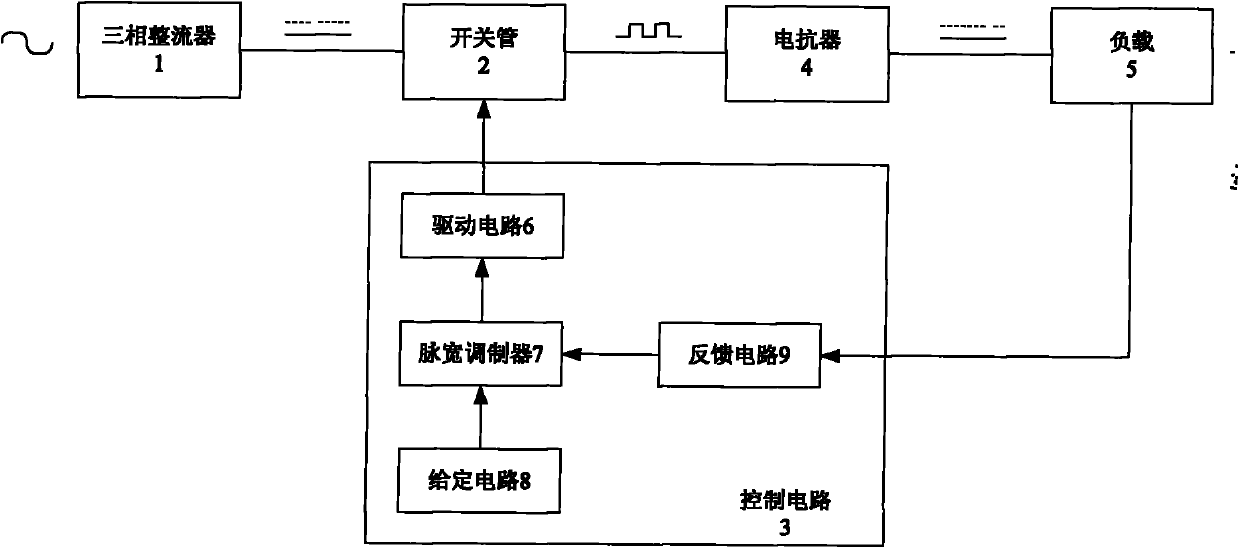

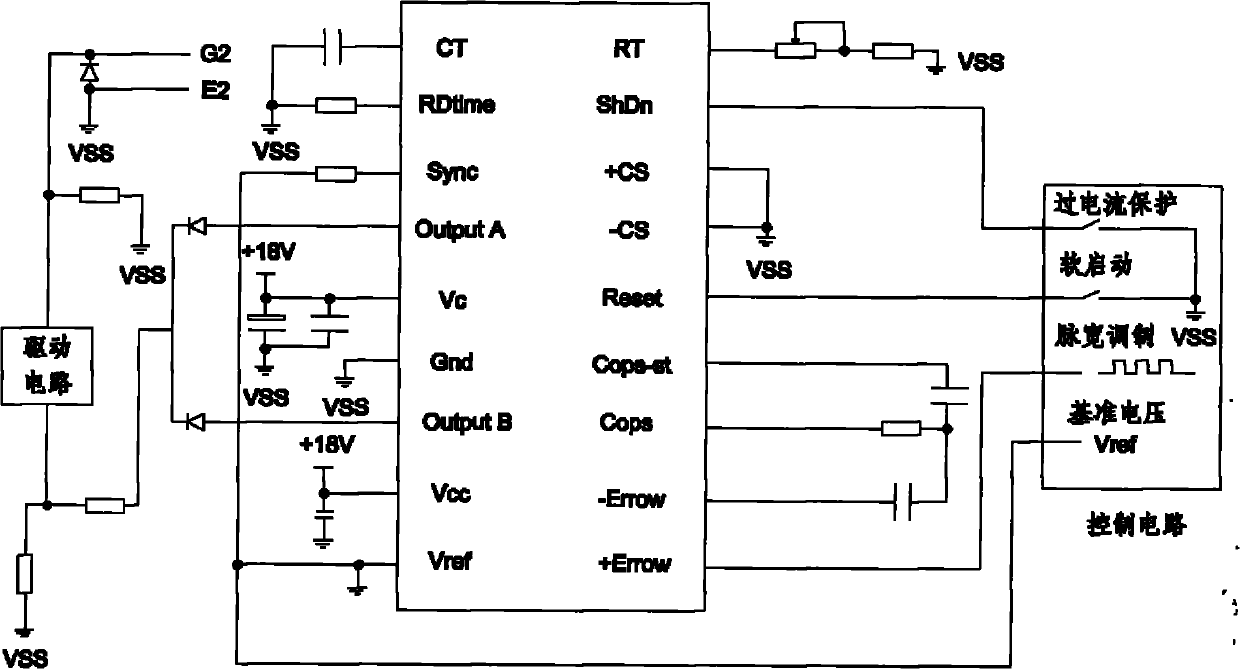

[0014] like figure 1 As shown, the present invention is connected between the power supply and the load 5, and is composed of a three-phase rectifier 1, a switching tube 2, a control circuit 3 and a reactor 4. The three-phase rectifier 1 , the switching tube 2 and the reactor 4 are sequentially connected, the reactor 4 is connected to the load 5 , and the control circuit 3 is connected between the switching tube 2 and the load 5 . Wherein the switch tube 2 is an insulated gate bipolar transistor. The control circuit 3 is composed of a drive circuit 6 , a pulse width modulator 7 , a given circuit 8 and a feedback circuit 9 . The switch tube 2 is connected to the driving circuit 6 and driven by the driving circuit 6 . The driving circuit 6 , the pulse width modulator 7 , and the given circuit 8 are sequentially connected, and the input of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com