Method for decomposing semi-hydrated phosphogypsum

A technology of hemihydrate phosphogypsum and phosphogypsum, applied in chemical instruments and methods, solid waste removal, inorganic chemistry and other directions, can solve the problems of low lime quality, low decomposition rate, low thermal efficiency, etc. Decomposition rate, the effect of improving desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Use the waste residue phosphogypsum produced by a phosphate fertilizer factory (the so-called phosphogypsum only refers to the gypsum discharged in the process of phosphating chemical industry, and its main component is still CaSO 4), the chemical composition is shown in Table 1, the fuel composition and industrial analysis are shown in Table 2, and pulverized coal is used as the reducing agent and fuel at the same time.

[0054] Table 1 Main chemical composition of phosphogypsum raw materials

[0055]

[0056] Table 2 Fuel composition and industrial analysis

[0057]

[0058] CaSO in raw material 4 0.5H 2 The O content is about 90% (dry basis), and the free water content is 70% can be discharged. The air flow rate required for normal temperature air is about 1.1-2t, and SO can be obtained. 2 Flue gas with mass percent concentration > 10% 2300Nm 3 .

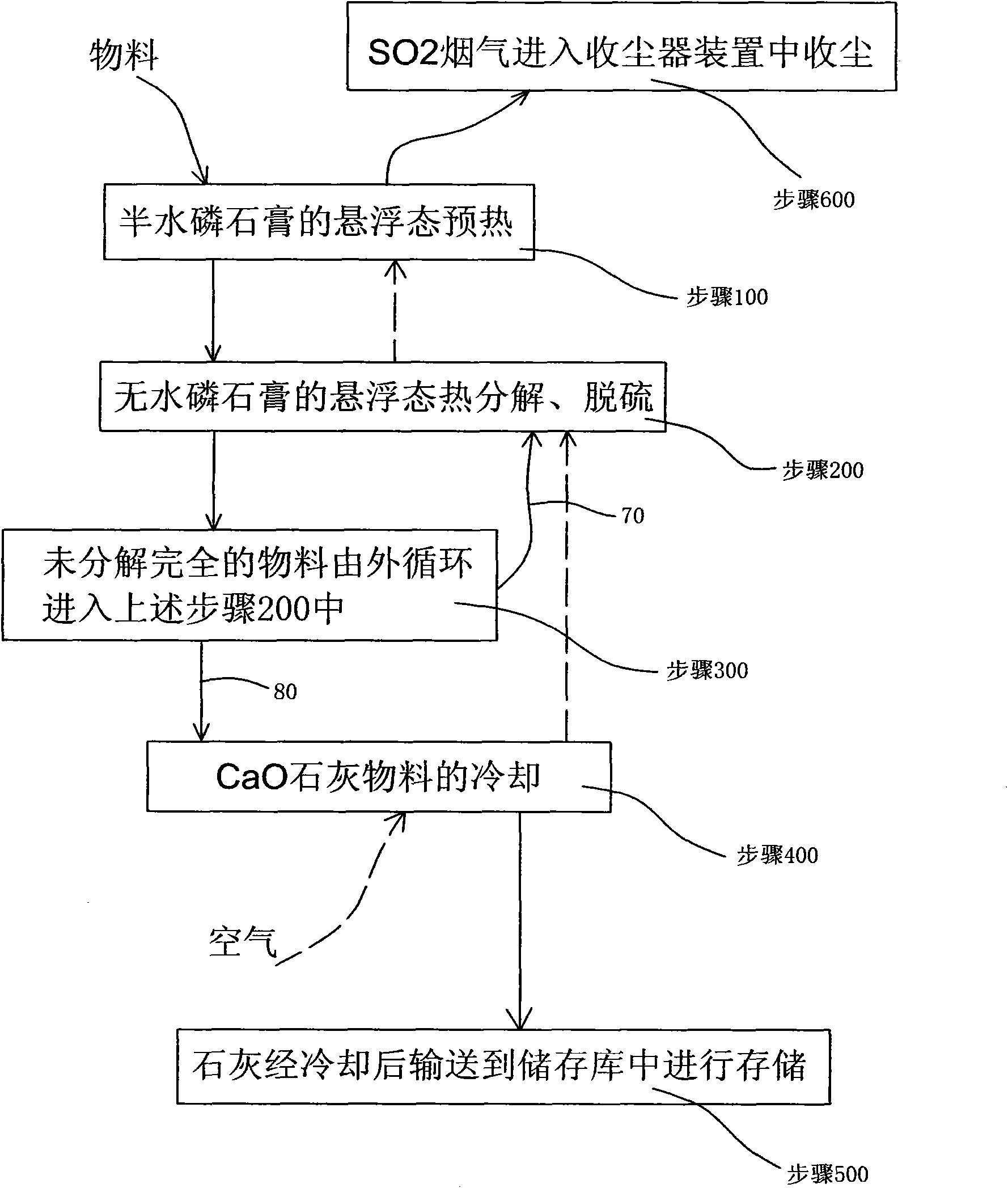

[0059] like figure 1 As shown, the present invention is concerned with feeding the dried and dehydrated hem...

Embodiment 2

[0072] Use the waste residue phosphogypsum produced by a phosphate fertilizer factory (the so-called phosphogypsum only refers to the gypsum discharged in the process of phosphating chemical industry, and its main component is still CaSO 4 ), its chemical composition, fuel composition and industrial analysis are shown in the above-mentioned Table 1 and Table 2, and coke is used as a reducing agent and a fuel at the same time. For every ton of phosphogypsum residue processed in this process, the amount of coke used is about 10kg. Other process conditions, including process control parameters, are the same as above.

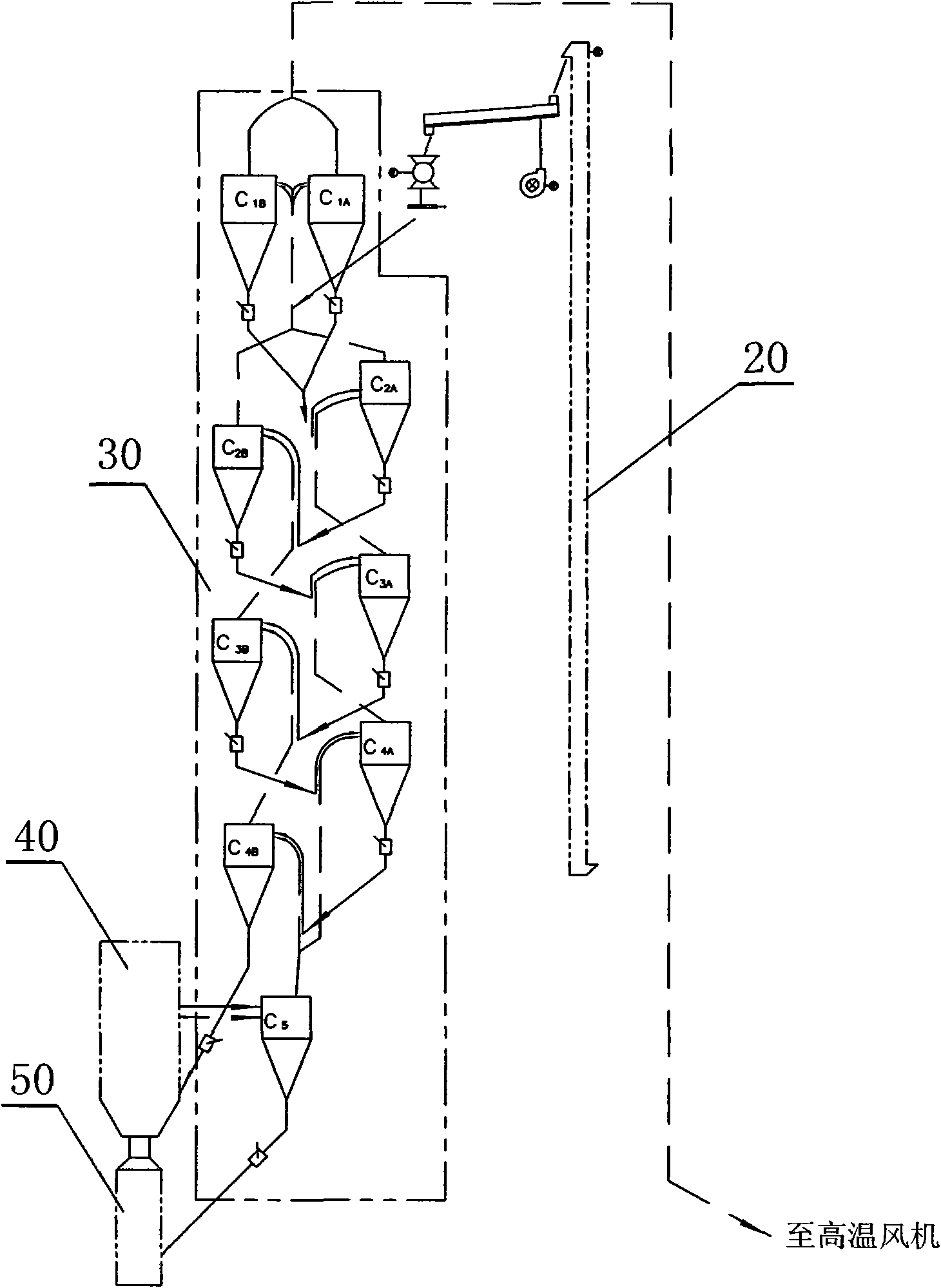

[0073] This is another embodiment of the present invention. In the process of material preheating and dehydration, the five-stage double-series preheater system in Embodiment 1 can be changed to a single-series preheater system.

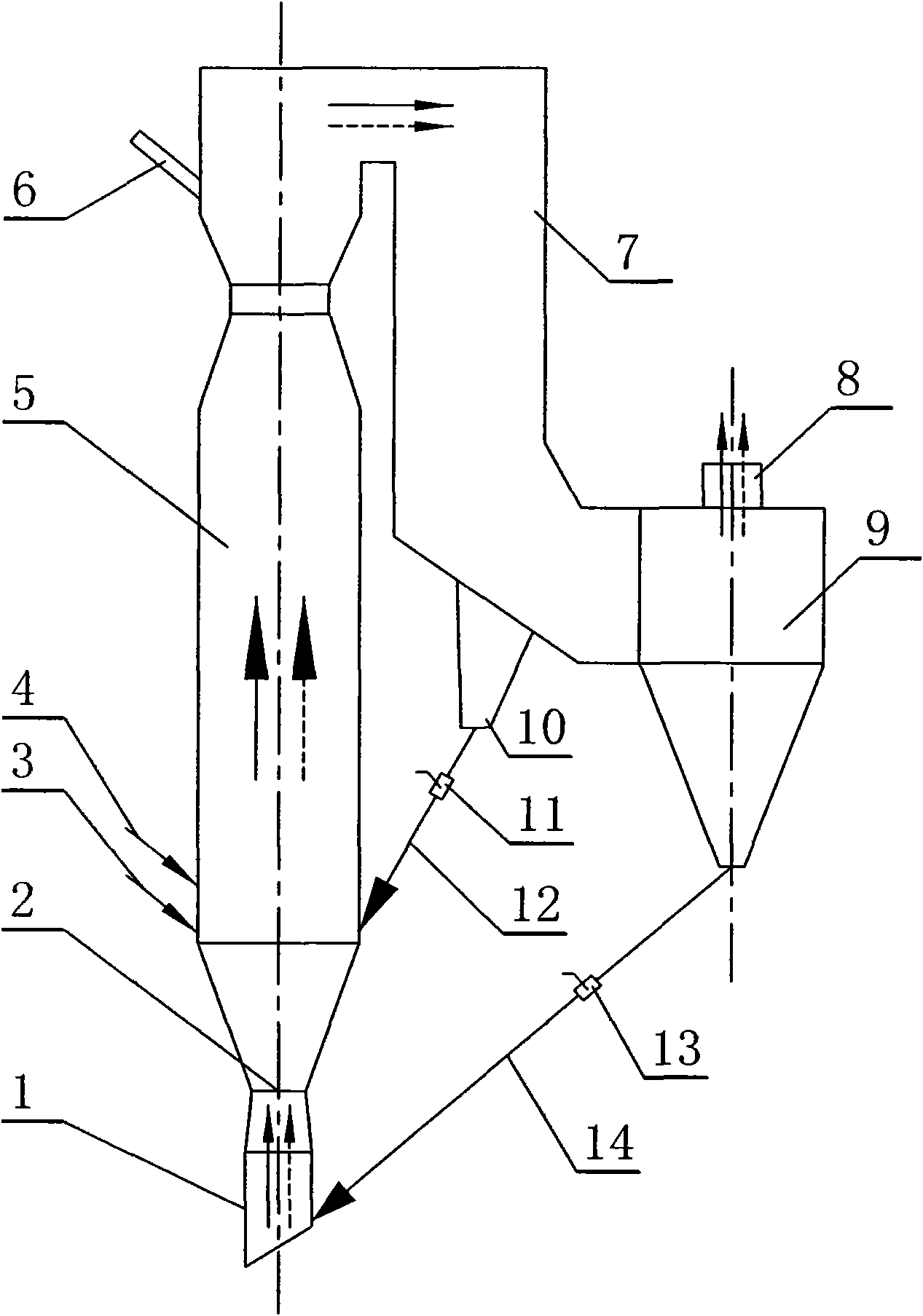

[0074] see again figure 2 and Figure 4 Shown is a structural schematic diagram of the main reaction system adopted in the decomposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com