Granular lithium ion sieve

A lithium ion, granular technology, applied in the field of granular lithium ion sieves, can solve the problems of poor adsorption performance of granular lithium ion sieves, difficult solid-liquid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Equipped with reflux condenser, stirring device, N 2 Add 200ml cyclohexane (oil phase) and 0.50g starch (dispersant) in the four-necked flask of conduit, 35 ℃, N 2 Pre-mixed evenly under the atmosphere;

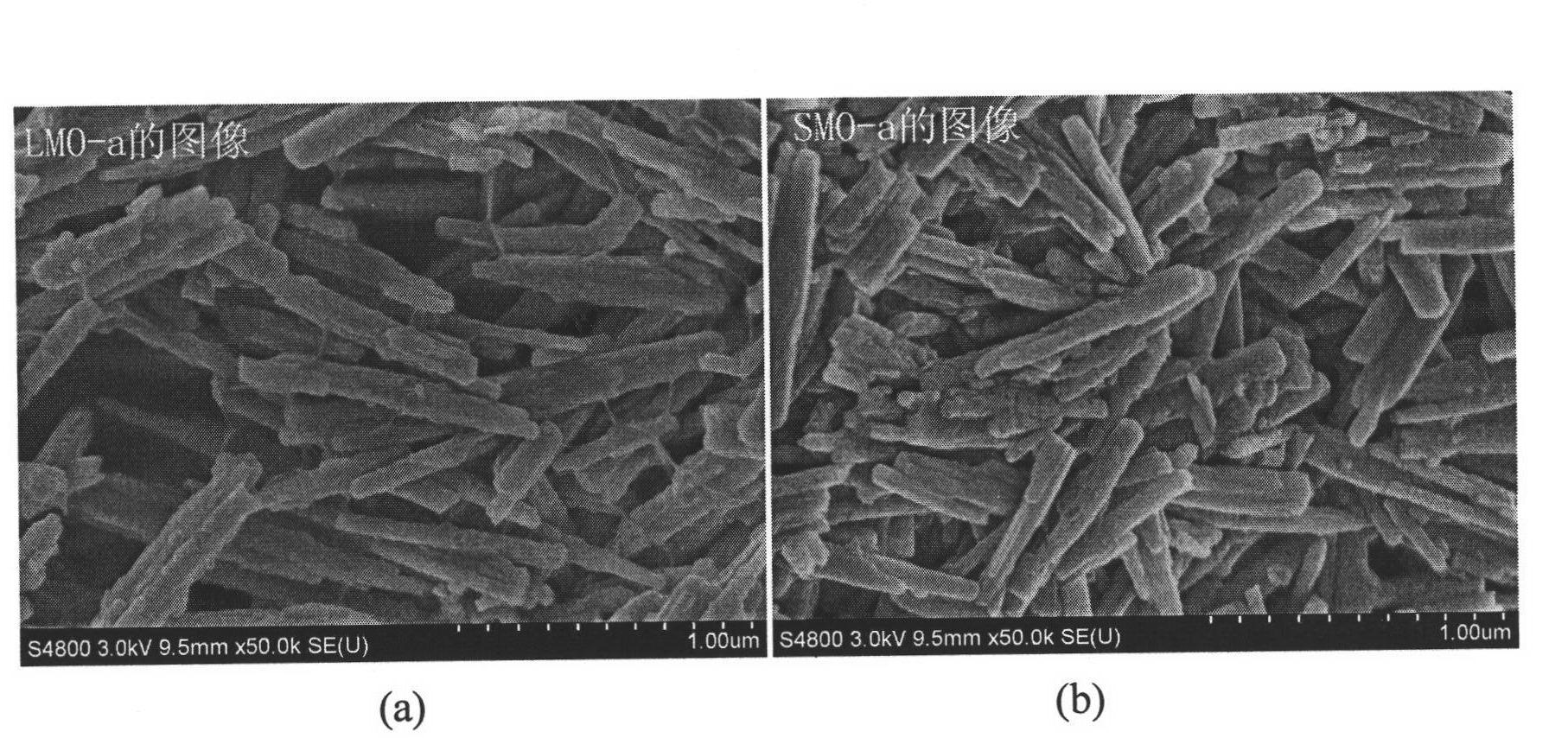

[0041] Dissolve 7.00g of acrylamide (monomer) and 0.14g of N,N-methylenebisacrylamide (crosslinker) in 20ml of deionized water, and add 7.00g of Li 4 mn 5 o 12 Powder, after stirring evenly, add 0.27g initiator ammonium persulfate, and quickly transfer it to the above-mentioned four-necked flask, stir vigorously, heat up to 65°C, N 2 Polymerize under atmosphere for 4 hours, cool to room temperature, wash the obtained particles with deionized water, and dry to obtain a granular ion sieve precursor (abbreviated as LMO-a). Use 1.0mol·l -1 HCl (H / Li=2, molar ratio) solution delithiates LMO-a, washes, and dries to obtain the target object (modified lithium ion sieve, abbreviated as SMO-a), with an average particle size of 1 mm to 2 mm. SEM image see figure 1 .

Embodiment 2

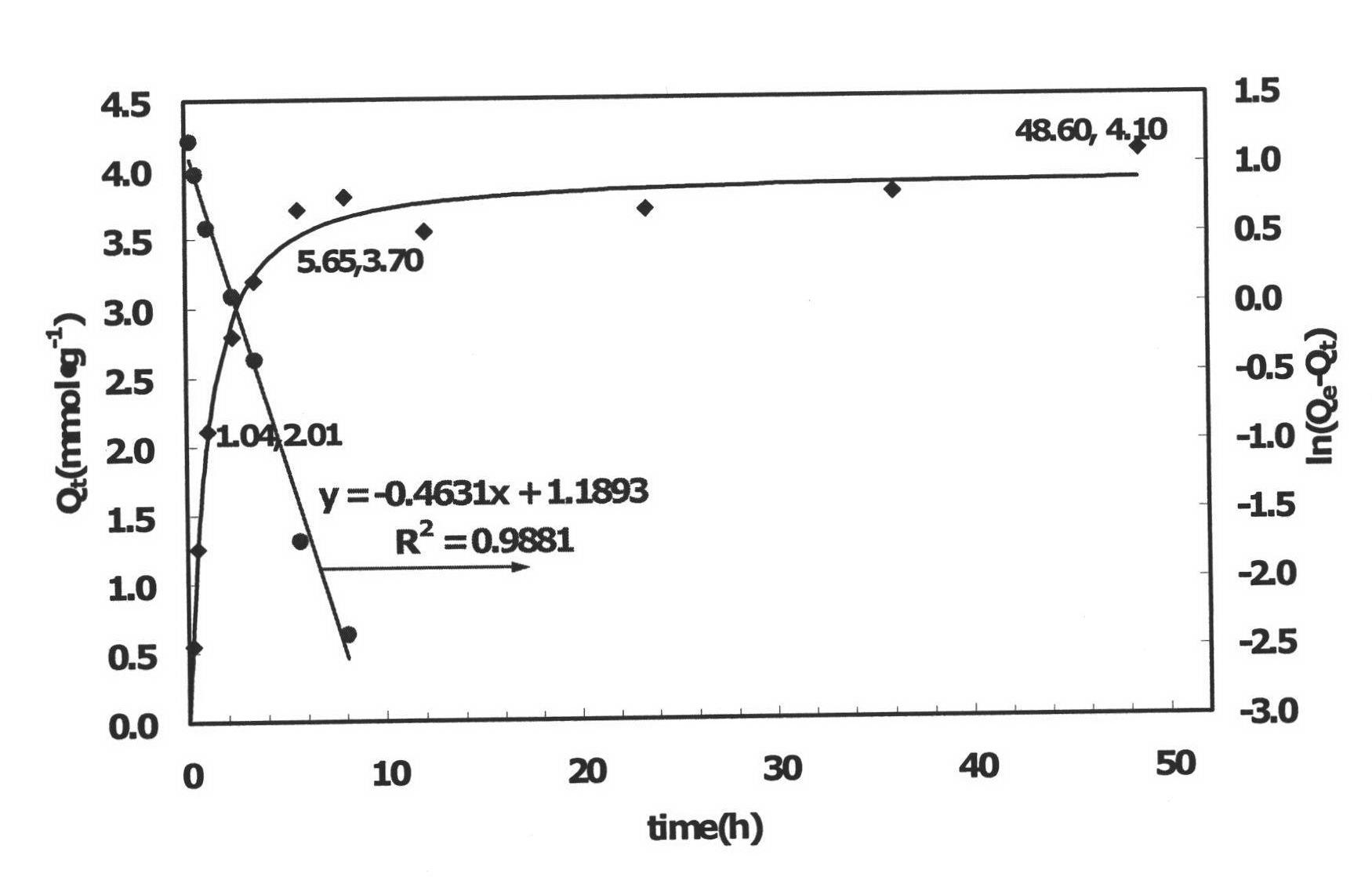

[0043] Weigh 0.2g of SMO-a respectively, and measure 0.010mol·1 -1 LiCl NH 3 ·H 2 O-NH 4 Cl buffer solution (pH value 9-11), mix the two and put them into a constant temperature oscillator for adsorption experiments. The adsorption temperature is 30°C and the rotation speed is 150r min -1 , respectively measure the concentration of lithium ions in the solution at different times, the results are shown in figure 2 .

[0044] Depend on figure 2 It can be seen that after SMO-a is adsorbed for 15 minutes, the adsorption amount is 0.54mmol g -1 , after 1.04 hours, the adsorption capacity exceeded 2mmol·g -1 , the saturated adsorption capacity is about 4.10mmol·g -1 . The adsorption rate constant k of the formed granular ion sieve SMO-a ads is 1.286×10 -4 the s -1 , in the same order of magnitude as the powdered ion sieve (the adsorption rate k of the powdered ion sieve ads 3.290×10 -4 the s -1 ). And the saturated adsorption capacity is equivalent to that of powder...

Embodiment 3

[0046] Equipped with reflux condenser, stirring device, N 2 Add 200ml hexanaphthene (oil phase) and 0.50gspan-80 (dispersant) in the four-neck flask of conduit, 20 ℃, N 2 Pre-mixed evenly under the atmosphere;

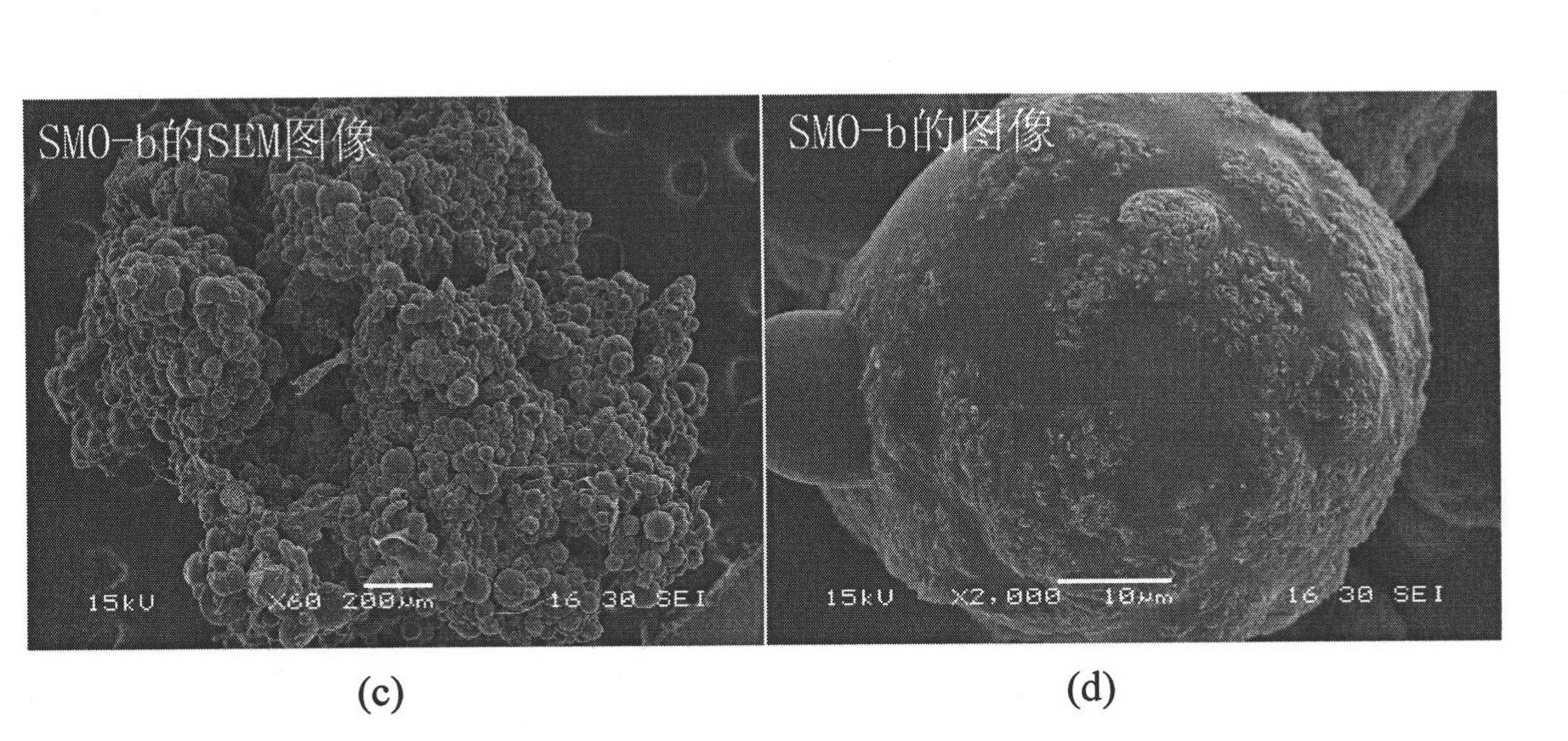

[0047] Dissolve 7.00g of acrylamide (monomer) and 0.14g of N,N-methylenebisacrylamide (crosslinker) in 10ml of deionized water, and add 14.00g of Li 4 mn 5 o 12 Powder, after stirring evenly, add 0.27g initiator potassium persulfate, and quickly transfer it to the above-mentioned four-necked flask, stir vigorously, and heat up to 70°C, N 2 Under the atmosphere, polymerize for 10 hours, cool to room temperature, and wash the obtained particles with deionized water completely, and dry to obtain a granular ion sieve precursor (abbreviated as LMO-b). -1 HCl solution delithiates LMO-b, washes, and dries to obtain the target object (abbreviated as SMO-b), whose average particle size is 1mm-2mm, and its SEM image is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com