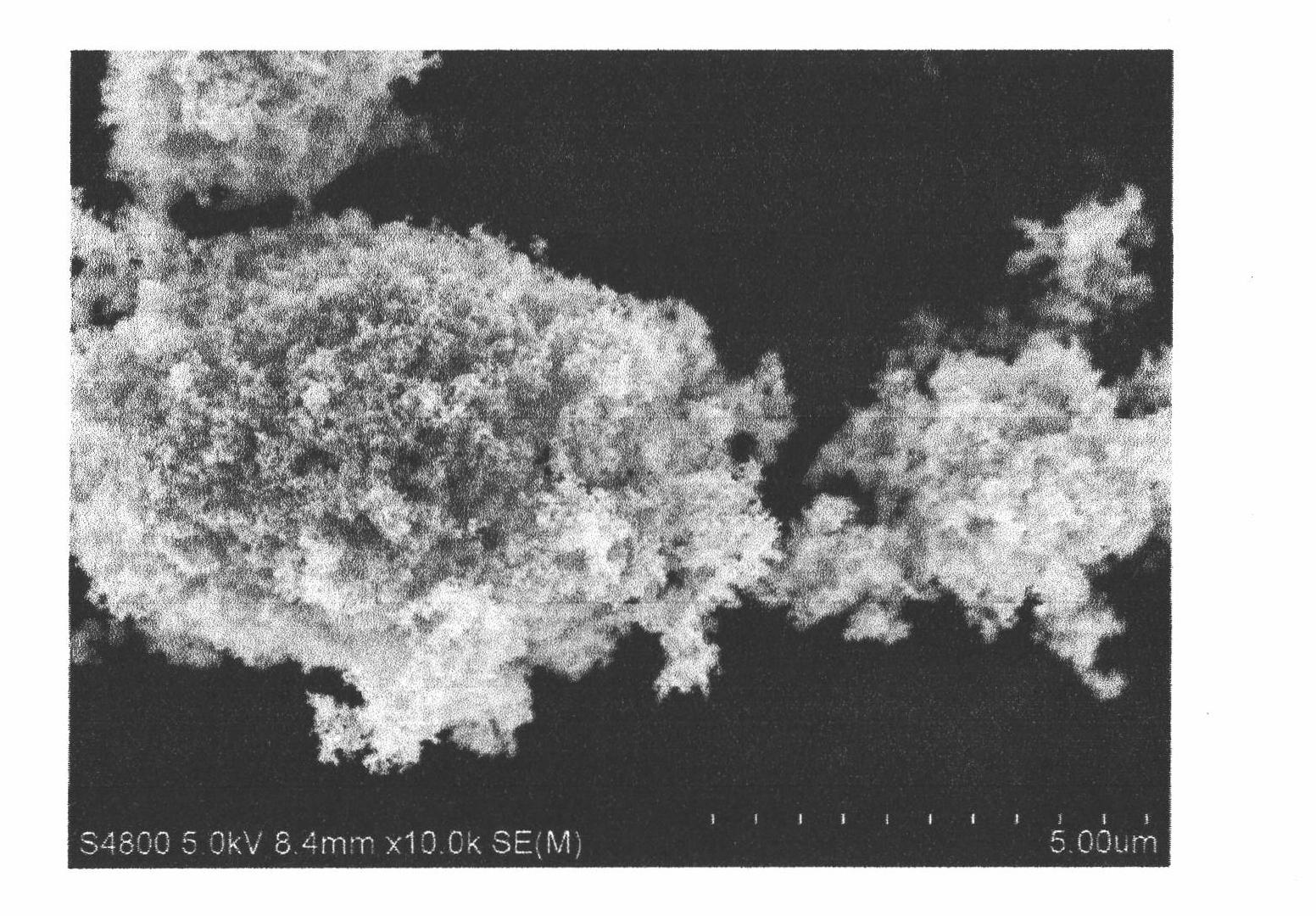

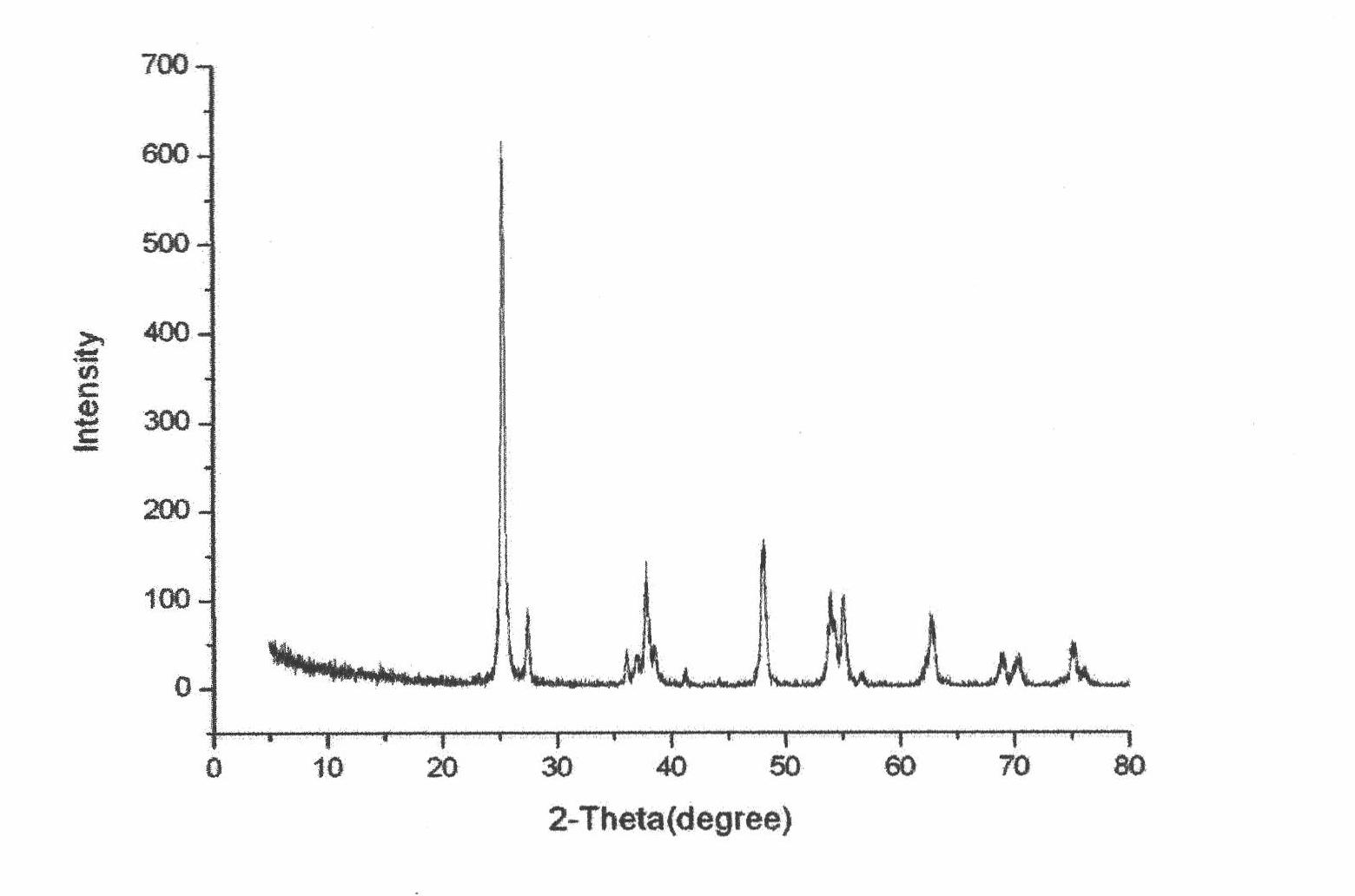

Method for preparing nano-titanium dioxide powder

A nano-titanium dioxide and powder technology, which is applied in the direction of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve the problems of difficult dispersion, difficulty in completeness, and large particle size of the powder, so as to achieve good preparation repeatability and improve production Efficiency and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1: preparing titanium dioxide hydrothermal reaction precursor. Measure a certain amount of n-butyl titanate and absolute ethanol, the volume ratio of n-butyl titanate and absolute ethanol is 4:1, stir magnetically for 0.5h to make it evenly mixed, and then continue to drop 0.5ml of distilled water to control The dropping rate was 0.5ml / min, and the stirring was continued after the dropping was completed to obtain a light yellow sol, which was then fully stirred for 1 hour to obtain a hydrothermal reaction precursor.

[0022] Step 2: microwave-hydrothermal synthesis reaction. Put the precursor obtained in step 1 into a polytetrafluoroethylene-lined reactor with a fixed filling degree of 70%, and tightly seal the reactor. The reaction kettle was placed in a microwave-assisted hydrothermal synthesizer, the reaction temperature was controlled at 180°C, the pressure was 1.0 MPa, and the reaction time was 90 minutes. After the required time was reached, the temperature ...

Embodiment 2

[0027] Step 1: preparing titanium dioxide hydrothermal reaction precursor. Measure a certain amount of n-butyl titanate and absolute ethanol, the volume ratio of n-butyl titanate and absolute ethanol is 5:1, and magnetically stir for 1 hour to make them evenly mixed. Then continue to add 1ml of distilled water dropwise, and control the dropping rate to 0.5ml / min. After the dropwise addition, continue to stir to obtain a light yellow sol, and then fully stir for 0.5h to obtain a hydrothermal reaction precursor.

[0028] Step 2: microwave-hydrothermal synthesis reaction. Put the precursor obtained in step 1 into a polytetrafluoroethylene-lined reactor with a fixed filling degree of 80%, and tightly seal the reactor. The reaction kettle was placed in a microwave-assisted hydrothermal synthesizer, the reaction temperature was controlled at 200°C, the pressure was 1.5 MPa, and the reaction time was 60 minutes. After the required time was reached, the temperature was cooled to room...

Embodiment 3

[0031] Step 1: preparing titanium dioxide hydrothermal reaction precursor. Measure a certain amount of n-butyl titanate and absolute ethanol, the volume ratio of n-butyl titanate and absolute ethanol is 6:1, then continue to drop 2ml of distilled water, control the dropping rate to 1ml / min, drop Stirring was then continued to obtain a pale yellow sol. Then fully stir for 1 h to obtain the hydrothermal reaction precursor.

[0032] Step 2: microwave-hydrothermal synthesis reaction. Put the precursor obtained in step 1 into a polytetrafluoroethylene-lined reactor with a fixed filling degree of 60%, and seal the reactor tightly. The reaction kettle was placed in a microwave-assisted hydrothermal synthesizer, the reaction temperature was controlled at 170°C, the pressure was 2.0 MPa, and the reaction time was 40 minutes. After the required time was reached, the temperature was cooled to room temperature by natural cooling.

[0033] Step 3: Wash and dry. The product obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com