Treatment method and treatment system of food wastes

The technology of a kitchen waste and a treatment method is applied in the field of a kitchen waste treatment method and a treatment system thereof, which can solve the problems of easy breeding of bacteria, mosquitoes, beetles, blockage of the urban sewer system, and failure to recycle and use them, and achieves suppression of The effect of re-breeding, preventing water loss, and enhancing plant resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

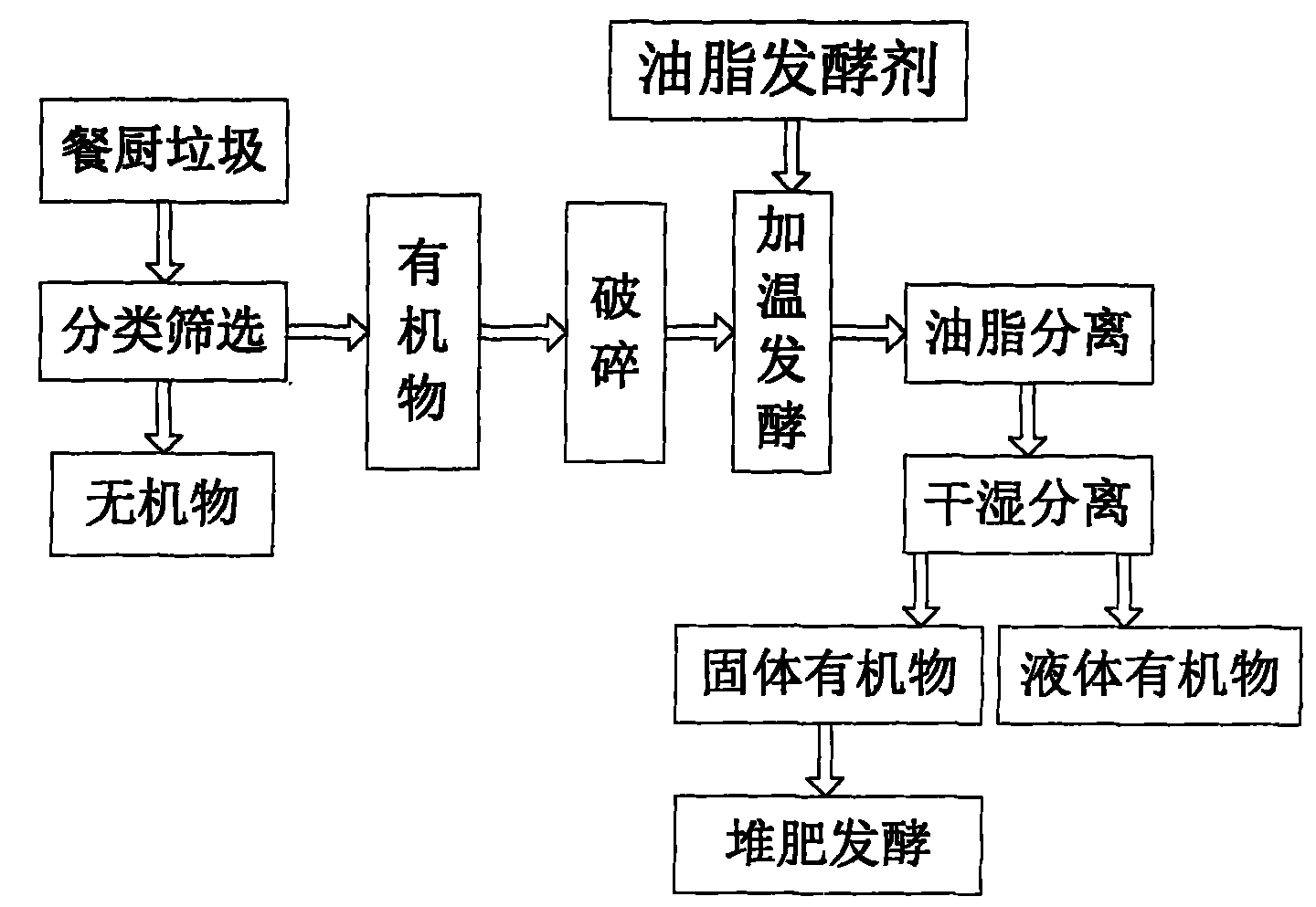

[0033] refer to figure 1 As shown, the present invention provides a kind of kitchen waste processing method, and it comprises the following steps:

[0034] Step 1) Sorting and screening: classify the collected kitchen waste according to organic matter and inorganic matter, recycle the inorganic matter, and wait for the organic matter to be processed;

[0035] Step 2) crushing: crushing the separated organic matter to obtain a mixture of organic waste particles with uniform particle size;

[0036] Step 3) Fermentation treatment: add a starter to the crushed garbage particle mixture, perform the first fermentation treatment, and obtain a fermented product;

[0037] Step 4) Grease Separation: Use a grease separator to separate the grease substances in the fermented product to obtain grease and deoiled fermented product. The separated grease can be reused for the production of biodiesel, cleaning soap, feed additives or hard Fatty acid and other uses;

[0038] Step 5) dry-wet s...

Embodiment 2

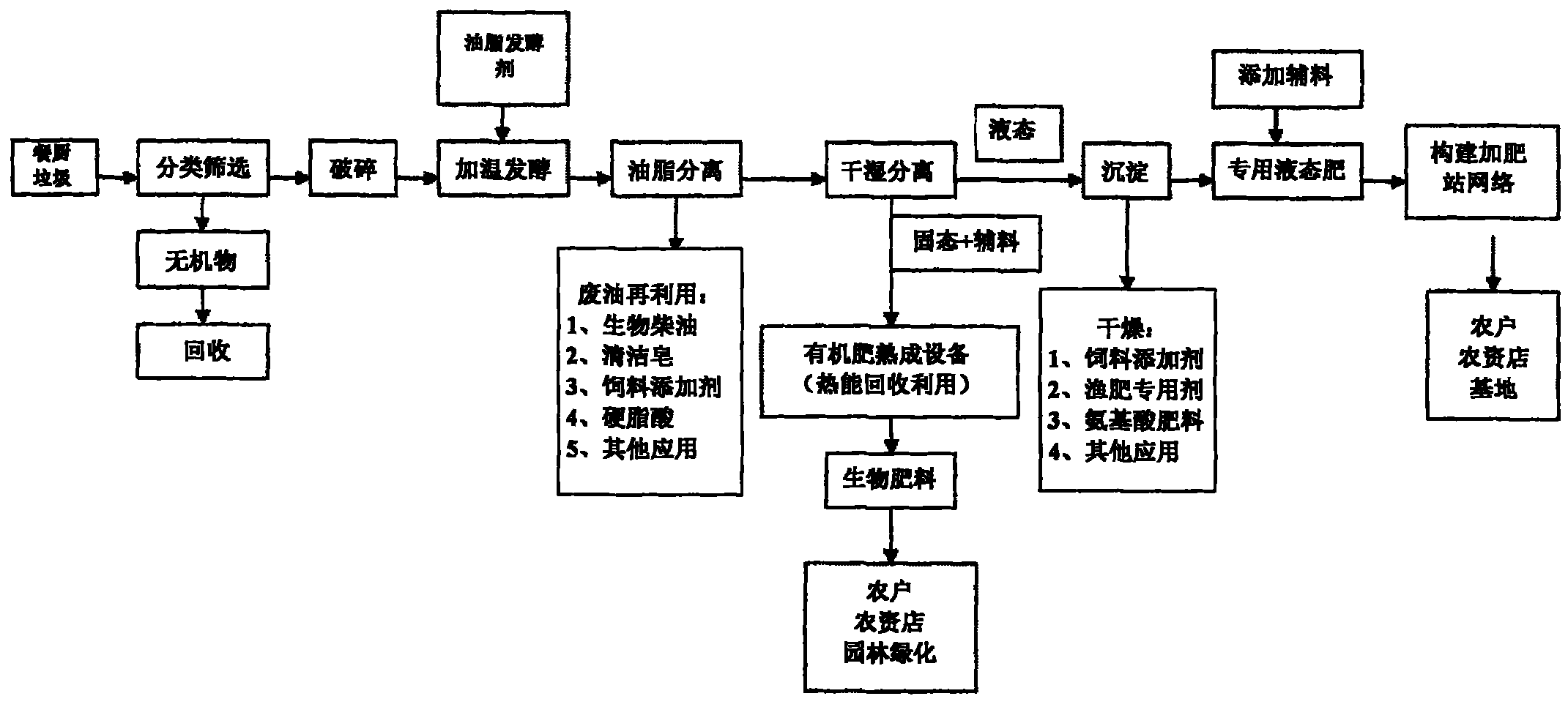

[0052] Such as figure 2 Shown is the flow chart of the kitchen waste treatment method of another preferred embodiment of the present invention:

[0053] (1) Use a special collection vehicle for food waste to send the food waste to the treatment plant;

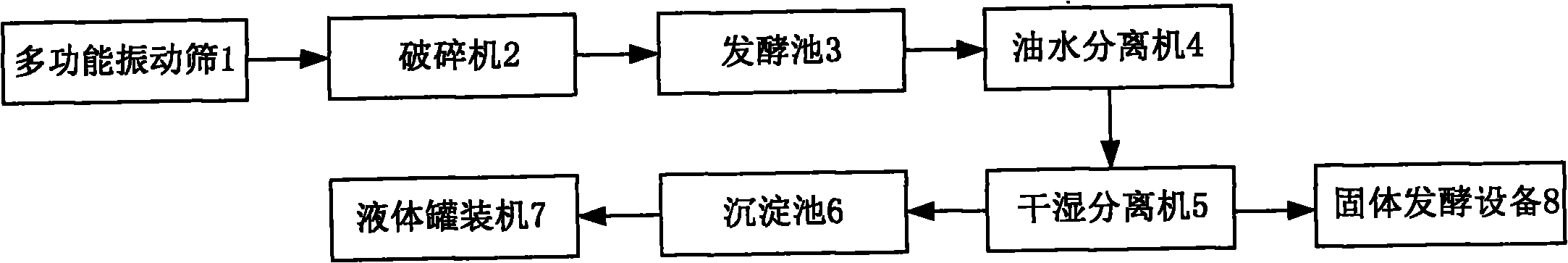

[0054] (2) Use a vibrating sieve to separate the organic matter and inorganic matter in the kitchen waste. The inorganic matter (such as mixed waste paper, waste plastic, etc.) will be screened out and enter the recycling stage; the separated organic matter will enter the next step;

[0055] (3) The organic matter is sent to the crusher on the conveyor belt, and the relatively large organic matter (such as animal bones, inedible parts of fruits, inedible parts of vegetables, etc.) is crushed to make the particle size of kitchen waste uniform , which is conducive to the carrying out of the first fermentation in the next step;

[0056] (4) After the organic matter is fully crushed, it enters the high-temperature fermentation s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com