Catalyst, method for producing the same, and use of the same

A manufacturing method and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as carbon and nitrogen oxides that have not been discussed, and achieve the effect of low-cost performance and high oxygen reduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] 1. Preparation of Catalyst

[0136] Titanium carbide (TiC) 5.10g (85mmol), titanium oxide (TiO 2 ) 0.80 g (10 mmol) and 0.31 g (5 mmol) of titanium nitride (TiN) were well mixed, and heated at 1800° C. in a nitrogen atmosphere for 3 hours to obtain 5.73 g of titanium carbonitride. Since it is a sintered body, the obtained titanium carbonitride was pulverized with an automatic mortar.

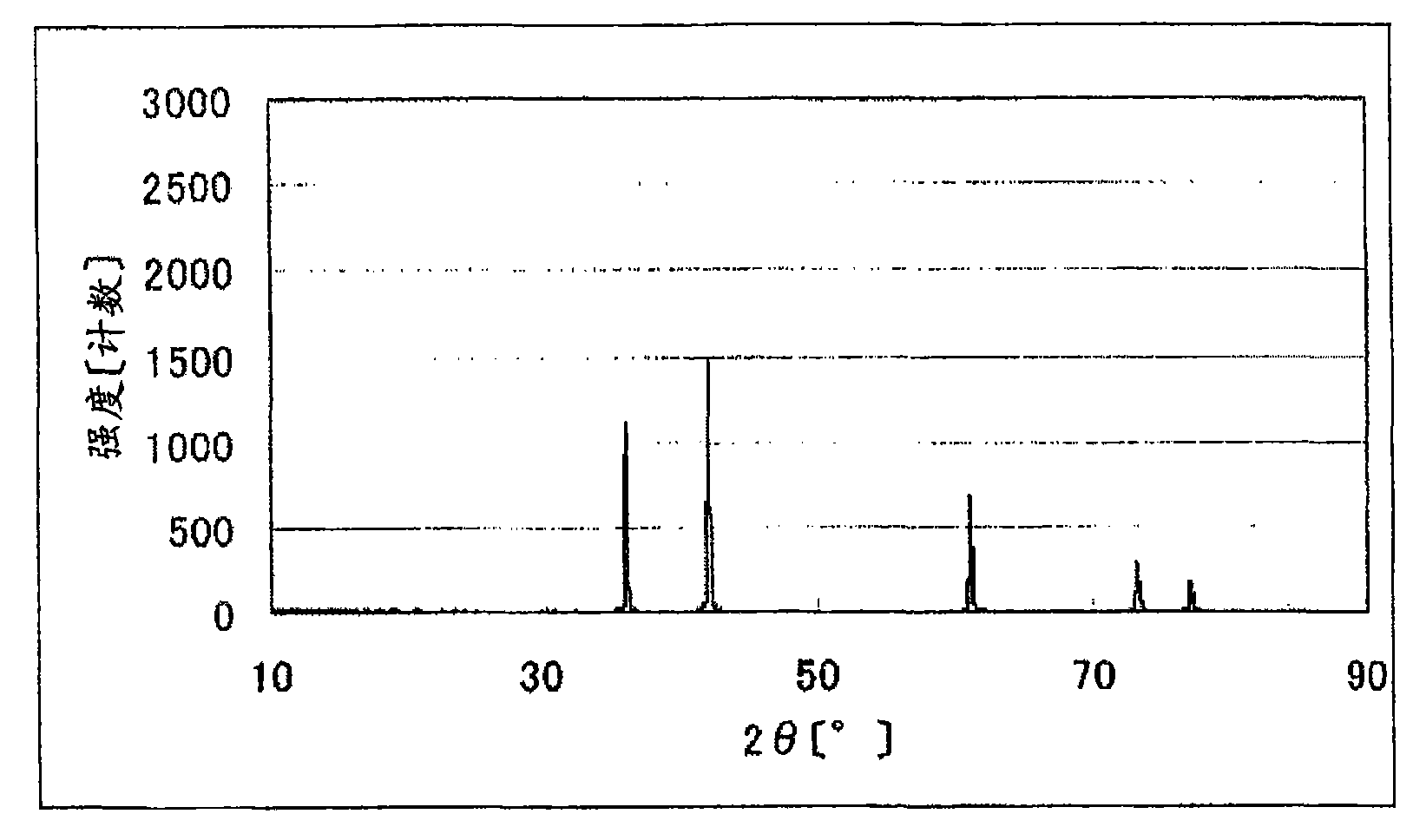

[0137] The powder X-ray diffraction spectrum of the obtained titanium carbonitride is shown in figure 1 .

[0138] In addition, Table 1 shows the elemental analysis results of the obtained titanium carbonitride.

[0139] While flowing nitrogen gas containing 1% by volume of oxygen and 4% by volume of hydrogen, 298 mg of the obtained titanium carbonitride was heated in a tubular furnace at 1000° C. for 10 hours to obtain titanium carbonitride (hereinafter also referred to as "Catalyst (1)".) 393mg.

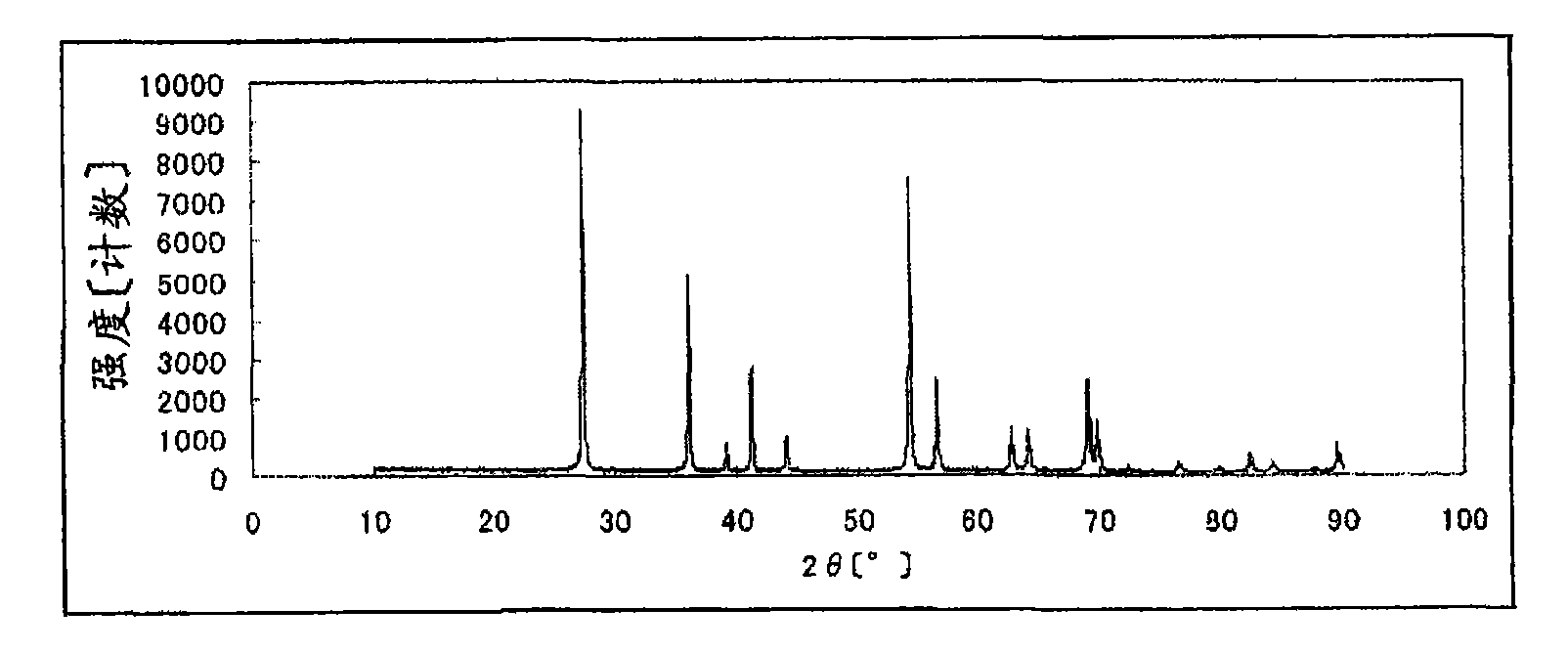

[0140] The powder X-ray diffraction spectrum of the catalyst (1) obtained is shown in...

Embodiment 2

[0153] 1. Preparation of Catalyst

[0154] While flowing nitrogen gas containing 1.5% by volume of oxygen and 4% by volume of hydrogen, 314 mg of titanium carbonitride obtained in Example 1 was heated in a tubular furnace at 1000° C. for 3 hours, thereby obtaining titanium carbonitride (Hereafter also referred to as "catalyst (2)".) 411 mg.

[0155]The powder X-ray diffraction spectrum of the catalyst (2) obtained is shown in Figure 4 .

[0156] In addition, the elemental analysis results of the catalyst (2) are shown in Table 1.

[0157] 2. Manufacture of electrodes for fuel cells

[0158] Except having used the above-mentioned catalyst (2), it carried out similarly to Example 1, and obtained the electrode (2) for fuel cells.

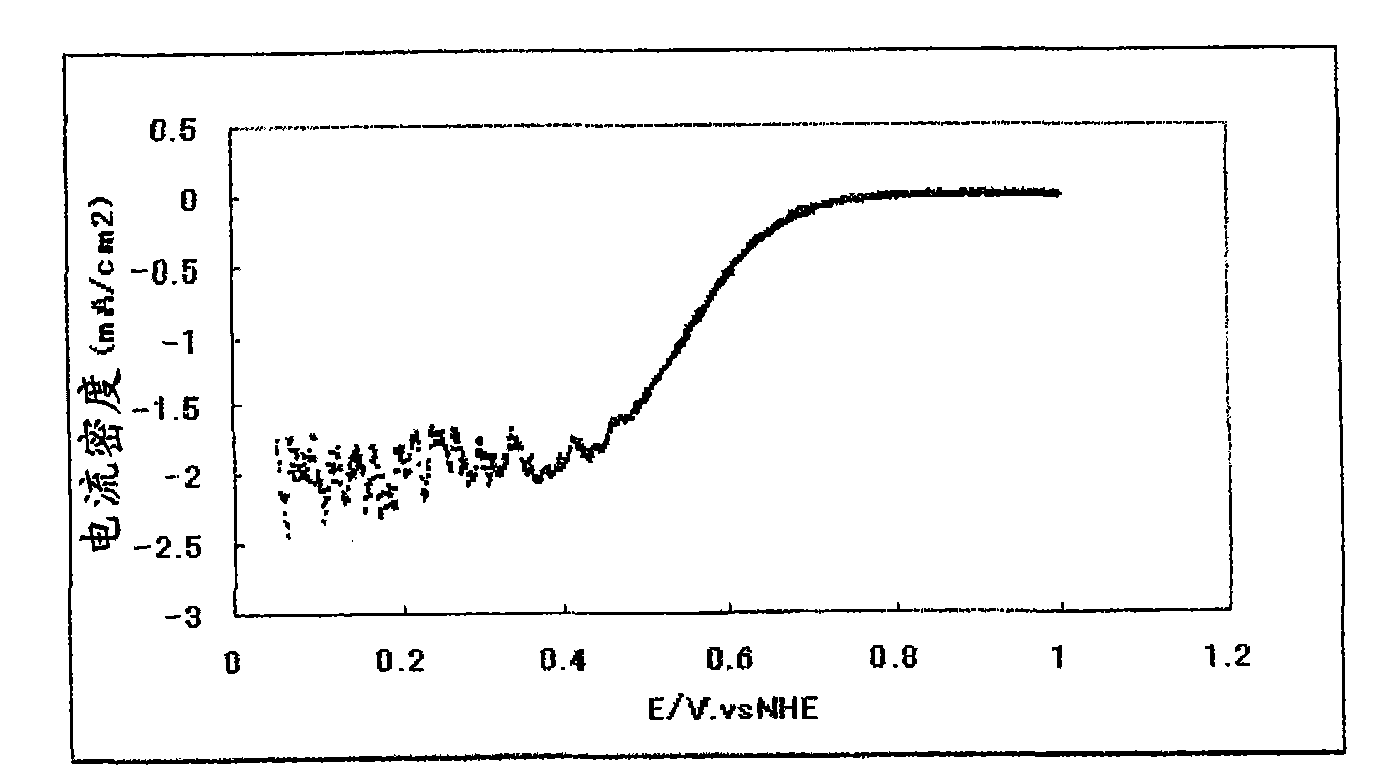

[0159] 3. Evaluation of Oxygen Reduction Capacity

[0160] The catalytic ability (oxygen reducing ability) was evaluated in the same manner as in Example 1, except that the fuel cell electrode (2) described above was used.

[0161] Figure 5 Th...

Embodiment 3

[0164] 1. Preparation of Catalyst

[0165] While flowing nitrogen gas containing 1.0% by volume of oxygen and 1.3% by volume of hydrogen, 314 mg of titanium carbonitride obtained in Example 1 was heated in a tubular furnace at 1000° C. for 3 hours, thereby obtaining titanium carbonitride (Hereafter also referred to as "catalyst (3)".) 415 mg.

[0166] The powder X-ray diffraction spectrum of the catalyst (3) obtained is shown in Figure 7 .

[0167] In addition, the elemental analysis results of the catalyst (3) are shown in Table 1.

[0168] 2. Manufacture of electrodes for fuel cells

[0169] Except having used the above-mentioned catalyst (3), it carried out similarly to Example 1, and obtained the electrode (3) for fuel cells.

[0170] 3. Evaluation of Oxygen Reduction Capacity

[0171] The catalytic ability (oxygen reducing ability) was evaluated in the same manner as in Example 1, except that the fuel cell electrode (3) described above was used.

[0172] Figure 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com