Chrome-free coating compositions for surface-treating steel sheet including carbon nanotube, methods for surface-treating steel sheet and surface-treated steel sheets using the same

A technology of surface treatment and carbon nanotubes, applied in the direction of conductive coatings, polyether coatings, nanotechnology, etc., can solve the problems of low conductivity, poor corrosion resistance, etc., and achieve the effect of solving energy-saving problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0055] Exemplary embodiments of the present invention will be described in more detail hereinafter. In this specification, the term "percentage (%)" used in the embodiments represents "% by weight" unless otherwise indicated.

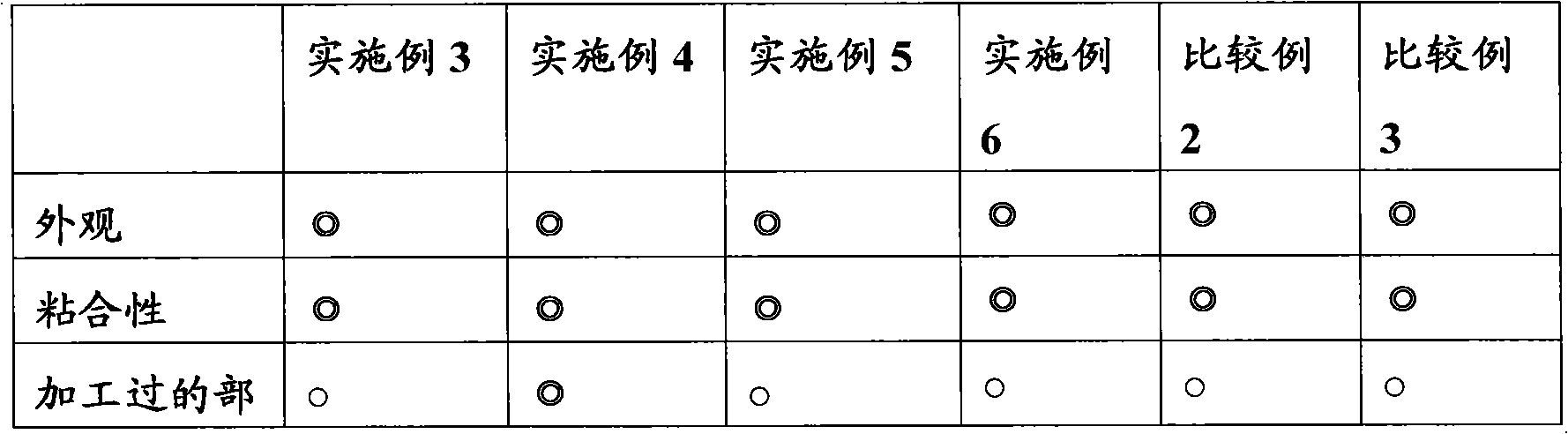

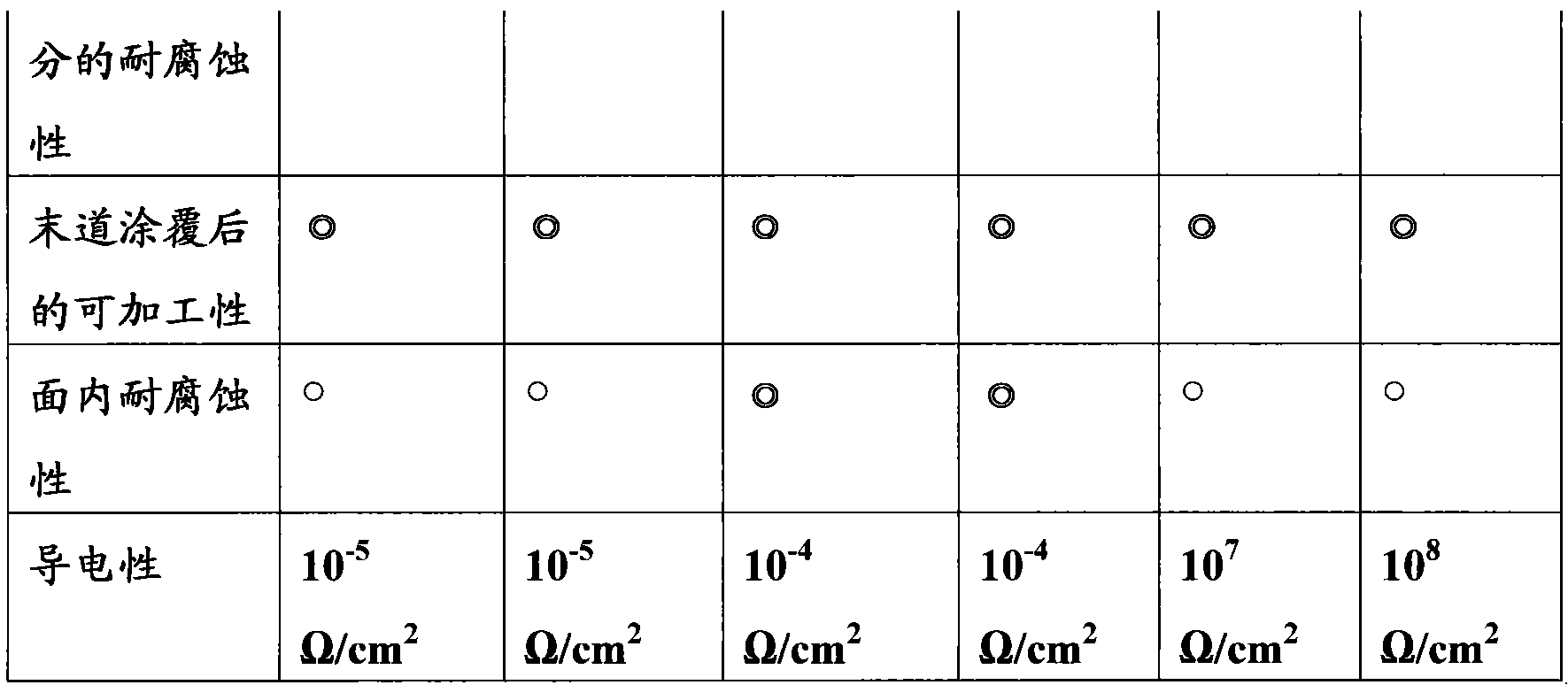

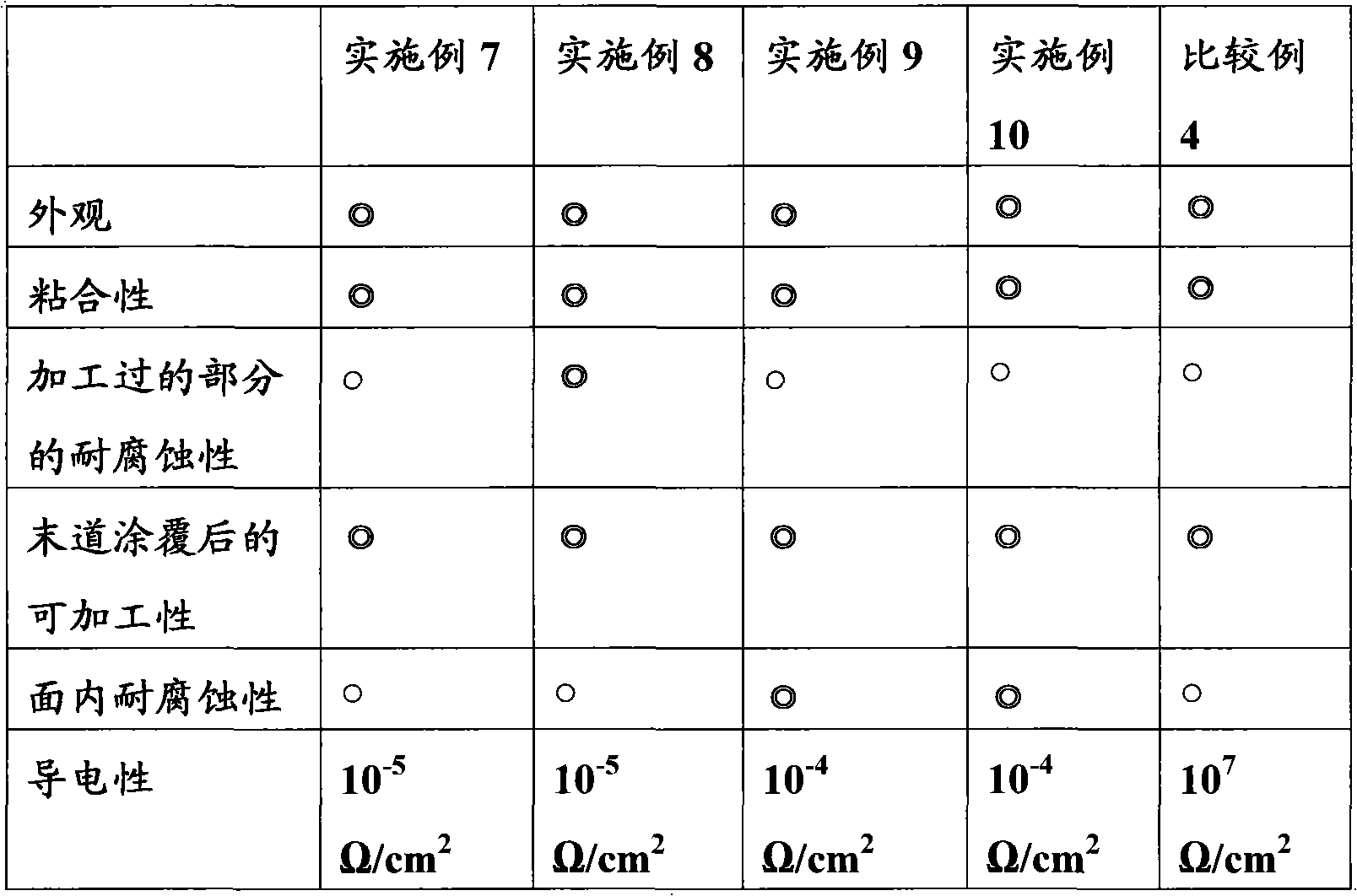

[0056] Appearance, adhesion, corrosion resistance of processed parts, workability after final coating of galvanized steel sheets treated with each of the coating compositions for surface treatment of steel sheets prepared in the following Examples and Comparative Examples were measured , in-plane corrosion and electrical conductivity.

[0057] (1) Appearance evaluation

[0058] The appearance of the steel sheet was evaluated by observing stains or peeling with the naked eye.

[0059] (2) Adhesiveness

[0060] The steel panels were cross-cut at a scale of 100 / 100 and tape tested using transparent adhesive strips.

[0061] (3) Corrosion resistance of processed parts

[0062] An Erichsen test was performed on a sample of the steel plate with a bending...

Embodiment 1

[0070] A coating composition for steel plate surface treatment (solid content: 20%) was prepared by dissolving the following components in a mixed solution of ethanol and water: 180 parts by weight of a carboxyl-containing water-dispersible polyurethane resin (solid content: 30%), 250 Parts by weight of water-soluble acrylic resin containing carboxyl (solid content: 20%), 20 parts by weight of carbon nanotube paste (solid content: 30%)--wherein carbon nanotubes (solid content: 13%) are distributed in water-dispersible polyurethane In the resin, 145 parts by weight of silica sol with a particle size of 20 to 30 nm (solid content: 30%), 30 parts by weight of 2-glycyloxypropyltrimethoxysilane (solid content: 72%), 8 Parts by weight of a phosphate aqueous solution of hexammonium heptamolybdate tetrahydrate (solid content: 63%) and 15 parts by weight of carbodiimide (solid content: 40%). Coating a steel plate with the prepared steel plate surface treatment coating composition, and ...

Embodiment 2

[0072] The coating composition for steel plate surface treatment was prepared in the same manner as in Example 1, except that the content of the carbon nanotube paste was 30 parts by weight. Coating the steel plate with the coating composition for surface treatment of the steel plate prepared, and then drying at a PMT of 120° C. to prepare wherein the coating amount of the coating composition is 1500 mg / m 2 galvanized steel sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com