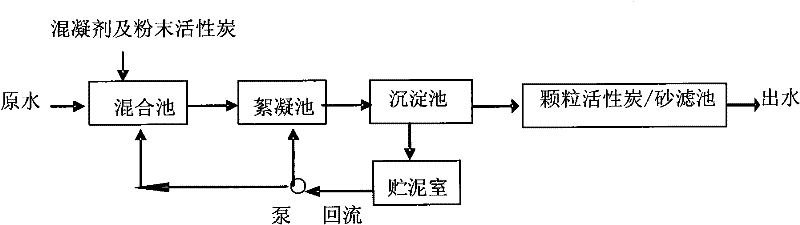

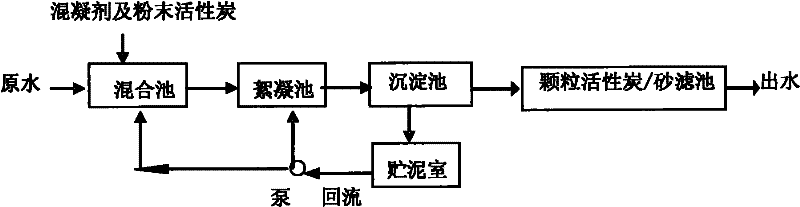

Powdered carbon backflow and carbon/sand filter combined process for treating polluted water

A technology of carbon sand filter and combined process, which is applied in the field of water treatment, to facilitate the response to sudden water pollution incidents, increase the floor area, and save chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the turbidity of the raw water to be treated is 4.62NTU, and the UV 254 0.0374cm -1 , ammonia nitrogen 2.907mg / L, pH value 7.6-8.0, water temperature 20-24°C, GSM 267.25ng / L, 2-MIB 274.87ng / L. Using the process of the present invention, the mechanical mixing tank, mechanical flocculation tank, inclined tube sedimentation tank, carbon / sand double-layer filter and powder carbon reflux process are combined, and powdered activated carbon and polyaluminum chloride are continuously added to the raw water. The dosage of aluminum is 15mg / L, the dosage of powdered activated carbon is 5mg / L, the hydraulic retention time of the mixing tank is 1min, and the G value is controlled at 800s -1 ;The hydraulic retention time of the flocculation tank is 15min, and the average G value is controlled at 50s -1 ; After sinking, the activated carbon mud flows back to the flocculation tank, the reflux ratio is controlled at 10%, and the mud age is 5 days; the thickness of ...

Embodiment 2

[0030] In this embodiment, the turbidity of the raw water to be treated is 4.02NTU, and the UV 254 0.0354cm -1, ammonia nitrogen 3.008mg / L, pH value 7.9, water temperature 19-24°C, GSM 257.45ng / L, 2-MIB 284.37ng / L. By adopting the process of the present invention, the mechanical mixing tank, the clapboard flocculation tank, the inclined tube sedimentation tank, the carbon / sand double-layer filter tank and the powder carbon reflux process are combined, and the powdered activated carbon, aluminum sulfate and coagulant aid are continuously added to the mixing tank. Acrylamide, the dosage of aluminum sulfate is 20mg / L, the dosage of powdered activated carbon is 6.0mg / L, the dosage of polyacrylamide is 0.1mg / L, the hydraulic retention time of the mixing tank is 0.5min, and the G value is controlled at 1000s -1 ; The hydraulic retention time of the flocculation tank is 20min, and the average G value is controlled at 30s -1 After sinking, the activated carbon mud flows back to the ...

Embodiment 3

[0032] In this embodiment, the turbidity of the raw water to be treated is 6.00NTU, and the UV 254 0.0256cm -1 , ammonia nitrogen 2.645mg / L, pH value 7.6, water temperature 20-22°C, GSM 242.06ng / L, 2-MIB 268.22ng / L. By adopting the process of the present invention, the mechanical mixing tank, the clapboard flocculation tank, the inclined tube sedimentation tank, the carbon / sand double-layer filter tank and the powder carbon reflux process are combined, and powdered activated carbon and polyaluminum chloride are continuously added to the mixing tank. The dosage of aluminum chloride is 20mg / L, the dosage of powdered activated carbon is 6.0mg / L, the hydraulic retention time of the mixing tank is 0.5min, and the G value is controlled at 900s -1 ; The hydraulic retention time of the flocculation tank is 18min, and the average G value is controlled at 20s -1 After sinking, the activated carbon mud flows back to the flocculation tank, the reflux ratio is controlled at 4%, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com