Method for removing sulfureted hydrogen through fixed bed of catalytic gasoline without liquid alkali

A technology for catalytic cracking gasoline and hydrogen sulfide removal, which is applied in the field of petrochemical industry, can solve the problems of high cost and low utilization rate of hydrogen sulfide removal catalyst in a single tower, and achieve the effect of reducing unit consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

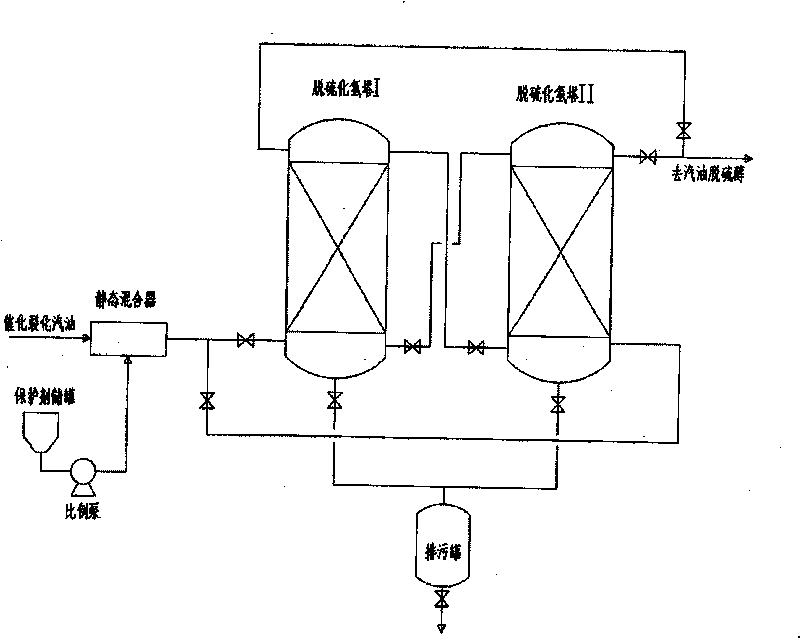

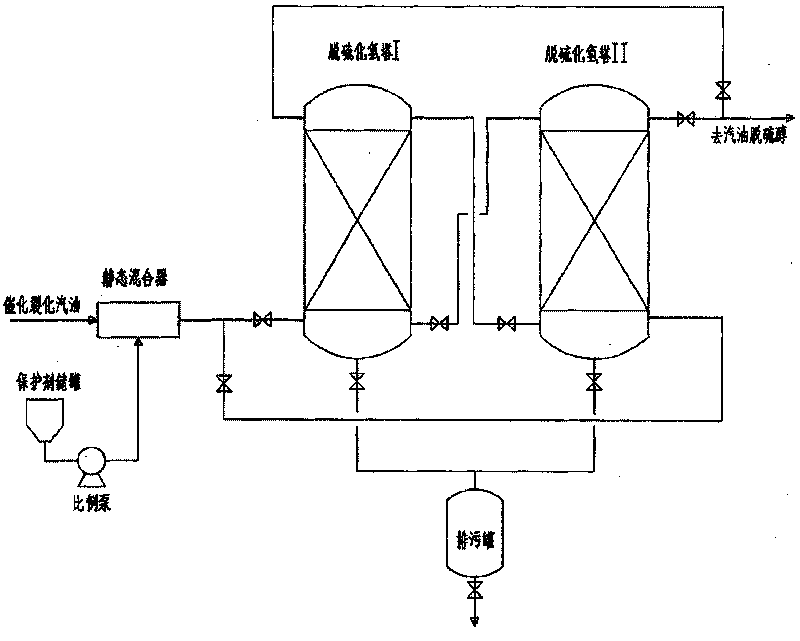

[0034] FCC gasoline is statically mixed with protective agent, and the catalyst reacts with hydrogen sulfide in gasoline at normal temperature and pressure to generate elemental sulfur, sulfide and hydrogen sulfide, which are adsorbed on the bed and discharged from the system through the sewage tank. To purify the bed and maintain the activity of the catalyst, dehydrogenation tower I and dehydrogenation tower II are used in series.

[0035] The method step of removing hydrogen sulfide is:

[0036] a, prepare catalyst: get 0.3Kg sodium hydroxide and pour into reactor, add water 2Kg, after fully dissolving, load on 9.5Kg into granular active carbon, be the prepared catalyst after drying;

[0037] b. Preparation of protective agent: take 0.3Kg of sodium hydroxide, add 0.75Kg of water, add 0.004Kg of dimethylguanidine, and then add 0.004Kg of cobalt phthalocyanine for dissolution;

[0038] c. Loading catalyst: according to the capacity of dehydrogenation tower I or II, the prepar...

Embodiment 2

[0045] FCC gasoline is statically mixed with protective agent, and the catalyst reacts with hydrogen sulfide in gasoline at normal temperature and pressure to generate elemental sulfur, sulfide and hydrogen sulfide, which are adsorbed on the bed and discharged from the system through the sewage tank. To purify the bed and maintain the activity of the catalyst, dehydrogenation tower I and dehydrogenation tower II are used in series.

[0046] The method step of removing hydrogen sulfide is:

[0047] a, prepare catalyst: get 0.5Kg potassium hydroxide and pour into reactor, add water 3Kg, spray on 16.2Kg granular activated carbon after fully dissolving, be catalyst after drying;

[0048] b. Preparation of protective agent: take 0.2Kg potassium hydroxide, add 2.5Kg of water to dissolve, add 0.1Kg trimethylguanidine, and add 0.01Kg sulfonated cobalt phthalocyanine to dissolve;

[0049] c. Loading catalyst: according to the capacity of dehydrogenation tower I or II, the prepared cat...

Embodiment 3

[0056] FCC gasoline is statically mixed with protective agent, and the catalyst reacts with hydrogen sulfide in gasoline at normal temperature and pressure to generate elemental sulfur, sulfide and hydrogen sulfide, which are adsorbed on the bed and discharged from the system through the sewage tank. To purify the bed and maintain the activity of the catalyst, dehydrogenation tower I and dehydrogenation tower II are used in series.

[0057] The method step of removing hydrogen sulfide is:

[0058] a, prepare catalyst: get 0.4Kg sodium bicarbonate and pour into reactor, add water 2.8Kg, after fully dissolving, load on 8Kg granular active carbon, be the catalyst of preparation after drying;

[0059] b. Preparation of protective agent: take 0.25Kg potassium hydroxide, add 1Kg of water, add 0.005Kg tetramethylguanidine, then add 0.005Kg polyphthalocyanine cobalt and dissolve it;

[0060] c. Loading catalyst: according to the capacity of dehydrogenation tower I or II, the prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com