Urushiol phosphorous-series flame retardant resin and preparation method thereof

A urushiol phosphorus-based and phosphorus-based flame retardant technology, applied in the direction of coating, can solve the problems of failing to maintain the excellent performance of raw lacquer, unable to overcome the problem of sensitization of raw lacquer, and achieve excellent medium resistance and excellent flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the above-mentioned urushiol phosphorus-based flame-retardant resin includes: separating and extracting urushiol from raw lacquer according to a conventional method, then adding a formulated amount of solvent to obtain an urushiol solution, and then adding a formulated amount of amine compounds to the urushiol solution , aldehyde compounds and catalysts, heated to 60-100°C, reacted for 2-6 hours, raised the temperature to remove the small molecule product water; ℃, react for 1 to 4 hours, stop heating and cool down to room temperature to obtain the urushiol phosphorus-based flame-retardant resin.

[0018] The urushiol is extracted from lacquer produced in Ankang, Hanzhong, Chengkou, Maoba, Qinling or other areas, with a frying fraction of more than 65% and a urushiol content of more than 50%.

[0019] The phosphorus compound is one or more of phosphorus oxide, phosphorus oxychloride, and phosphate ester.

[0020] The amine compound is one or m...

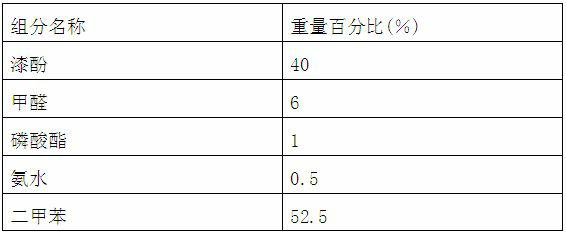

Embodiment 1

[0024] The weight percent of urushiol phosphorus flame retardant resin raw material of the present invention is as follows:

[0025]

[0026] The urushiol is extracted from lacquer produced in Ankang, Hanzhong, Chengkou, Maoba, Qinling or other areas according to conventional methods, the frying fraction is more than 65%, and the urushiol content is more than 50%.

[0027] Add formula amount of xylene to urushiol extracted from raw lacquer to obtain urushiol solution, heat urushiol solution to 60°C, add formula amount of formaldehyde and ammonia water to react for 1-3 hours, heat up and dehydrate, wait until the temperature of the system rises to At 110°C, add the formulated amount of phosphoric acid ester, react for 1-3 hours, and cool down to room temperature after the reaction, to obtain the urushiol phosphorus-based flame-retardant resin.

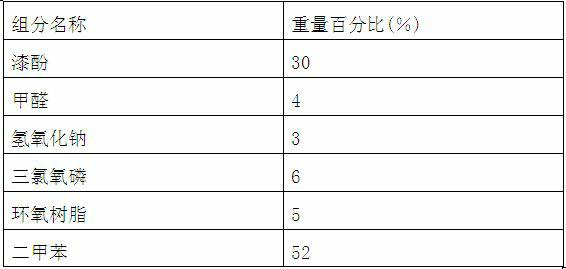

Embodiment 2

[0029] The raw material and weight percent of urushiol phosphorus flame retardant resin of the present invention are as follows:

[0030]

[0031] The urushiol is extracted from lacquers produced in Ankang, Hanzhong, Chengkou, Maoba, Qinling or other areas according to conventional methods.

[0032] To the urushiol extracted from raw lacquer, add the formulated amount of xylene to obtain the urushiol solution, heat the urushiol solution to 60°C, add the formulated amount of aniline, furfural and sodium hydroxide to react for 2-5 hours, heat up and dehydrate, and wait for the system The temperature rises to 90°C, and the formulated amount of phosphorus oxide is added, reacted for 2-4 hours, and after the reaction is completed, the temperature is lowered to room temperature, and the urushiol phosphorus-based flame-retardant resin is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com