Gold-bearing viscose and preparation method thereof

A viscose fiber, gold-loading technology, applied in fiber processing, medical science, absorbent pads, etc., can solve the problems of difficult control of nano-silver agglomeration, nano-silver oxidation, discoloration, application safety problems, etc., and achieve good reducibility and safety. Stability, stable solution properties, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

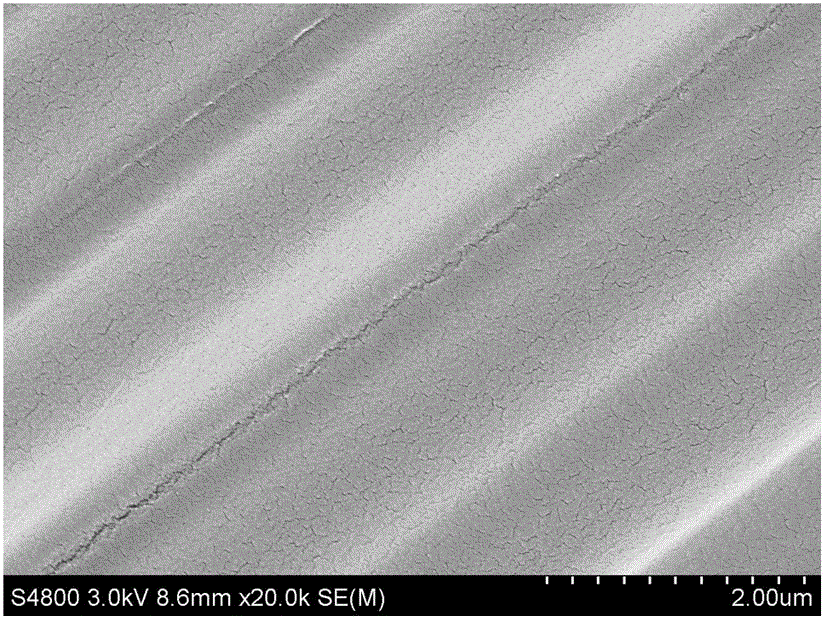

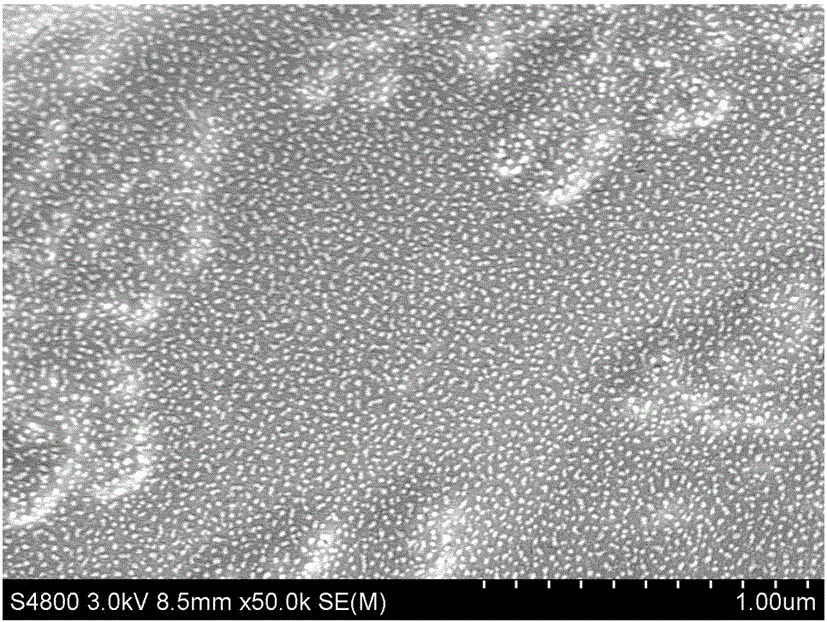

Image

Examples

Embodiment 1

[0025] A method for preparing a nano-gold solution. The specific steps are: dissolving 5g of β-cyclodextrin powder in 95g of deionized water, the temperature of the aqueous solution is 80°C, and stirring for 6 hours at 200 rpm until a transparent β-cyclodextrin is obtained. Fine aqueous solution; add 2g of sodium chloride powder into the β-cyclodextrin aqueous solution, continue stirring for 0.5h until the sodium chloride powder is completely dissolved; then add 0.5g of tetrachloroauric acid into the β-cyclodextrin containing sodium chloride In the aqueous solution, after stirring for 5 minutes to dissolve, insert the positive and negative electrodes of a DC power supply with a current of 0.5A and a voltage of 10V into the solution, increase the stirring speed to 1000 rpm, and put the prepared solution into a centrifuge after reacting for 2 hours After centrifuging for 10 min at 1000 rpm, impurities were removed to prepare a nano-gold solution.

[0026] Take 5 g of washed visc...

Embodiment 2

[0028] A method for preparing a nano-gold solution, the specific steps are: select 10g of β-cyclodextrin powder and dissolve it in 90g of deionized water, the temperature of the aqueous solution is 90°C, and stir at 400 rpm for 6 hours until a transparent β-cyclodextrin is obtained Fine aqueous solution; add 5g of sodium chloride powder into the β-cyclodextrin aqueous solution, and continue to stir for 1 hour until the sodium chloride powder is completely dissolved; then add 0.8g of tetrachloroauric acid into the β-cyclodextrin aqueous solution containing sodium chloride After stirring for 5 minutes to dissolve, insert the positive and negative electrodes connected to the DC power supply into the solution, adjust the current to 0.01-1A, the voltage to 5-30V, increase the stirring speed to 1500 rpm, and react for 4 hours. Put it into a centrifuge, centrifuge at 1000 rpm for 10 minutes, and then remove impurities to prepare a nano-gold solution.

[0029] Take 5 g of washed visco...

Embodiment 3

[0031] A method for preparing a nano-gold solution, the specific steps are: select 2g of β-cyclodextrin powder and dissolve it in 98g of deionized water, the temperature of the aqueous solution is 80°C, and stir at 200 rpm for 6 hours until a transparent β-cyclodextrin is obtained Fine aqueous solution; add 1g of sodium chloride powder into the β-cyclodextrin aqueous solution, continue stirring for 0.5h until the sodium chloride powder is completely dissolved; then add 0.2g of tetrachloroauric acid into the β-cyclodextrin containing sodium chloride In the aqueous solution, after stirring for 5 minutes to dissolve, insert the positive and negative electrodes connected to the DC power supply into the solution, adjust the current to 0.5A, the voltage to 5-30V, increase the stirring speed to 1000 rpm, and react for 2 hours. Put it into a centrifuge, centrifuge at 1000 rpm for 10 minutes, and then remove impurities to prepare a nano-gold solution.

[0032] Take 5 g of washed viscos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com