Reversible electrochromism composite fiber and preparation method thereof

A composite fiber and carbon nanotube fiber technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems such as the difficulty of conformational transformation of polydiyne, and achieve the effect of wide application potential and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

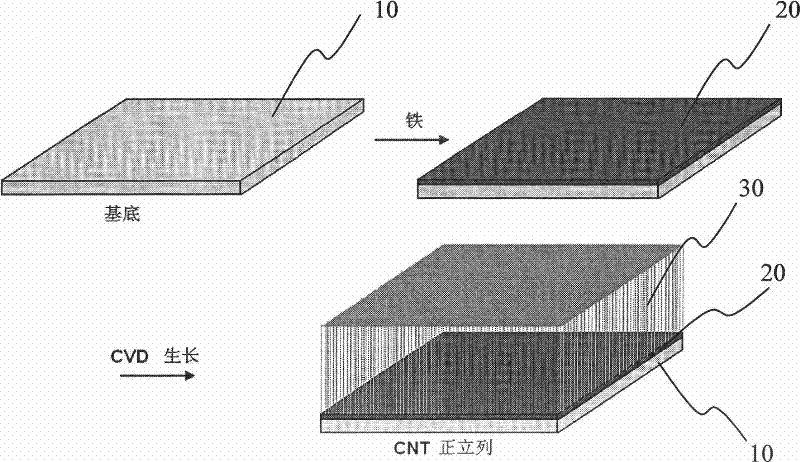

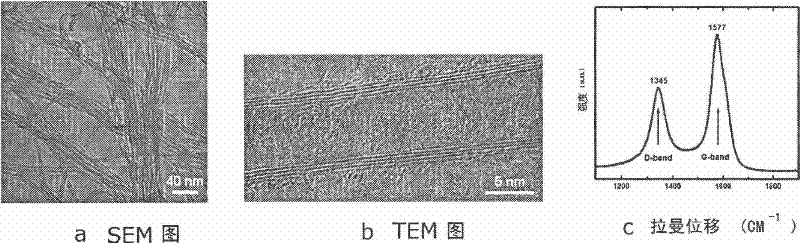

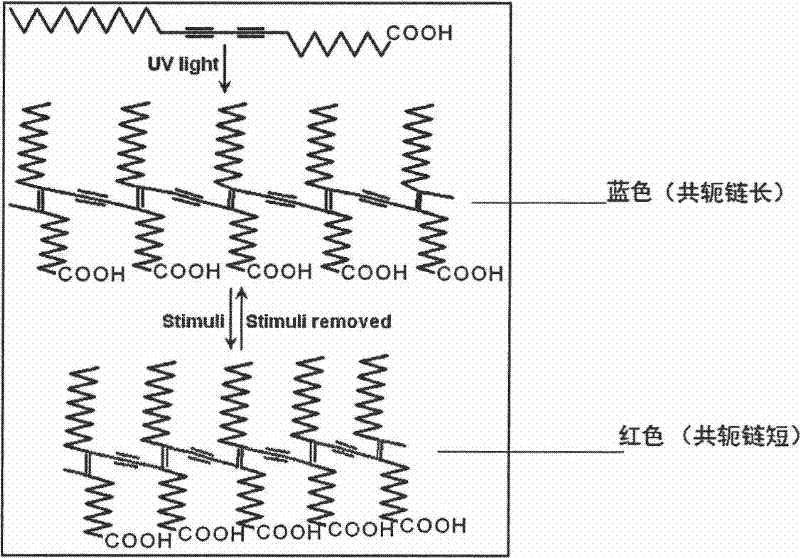

Method used

Image

Examples

specific example 1

[0036] The monomer CH 3 (CH 2 ) 11 C≡C-C≡C(CH 2 ) 8 COOH was dissolved in tetrahydrofuran to prepare a 10mg / ml diacetylene monomer solution. Then, the carbon nanotube fibers with a diameter of 11 μm were immersed in the diacetylene monomer solution for 10 minutes, and the solvent was volatilized at room temperature after being taken out. Place in a fume hood for 24 hours. A UV lamp with a wavelength of 254 nm was used to irradiate 17 cm away from the fiber for 1 hour to polymerize the diacetylene monomer on the fiber to obtain a blue carbon nanotube / polydiyne composite fiber. Take a section of fiber and fix it on the glass substrate, and connect the two ends with silver glue and gold wire. The gold wire is connected to the current source, and the current is passed through. When the current value is continuously increased, the composite fiber does not change significantly when the current is less than 10mA. When the current is greater than 10 mA and less than 30 mA, the compo...

specific example 2

[0038] The monomer HOOC(CH 2 ) 8 C≡C-C≡C(CH 2 ) 8 COOH was dissolved in tetrahydrofuran to prepare a 10mg / ml diacetylene monomer solution. Then the carbon nanotube fibers with a diameter of 11 μm were immersed in the diacetylene monomer solution for 30 minutes, and the solvent was volatilized at room temperature after being taken out. Place in a fume hood for 24 hours. A UV lamp with a wavelength of 254nm was irradiated at a distance of 17 cm from the fiber for 1.5 hours to polymerize the diacetylene monomer on the fiber, and the blue carbon nanotube / polydiyne composite fiber was also obtained. Take a section of fiber and fix it on the glass substrate, and connect the two ends with silver glue and gold wire. The gold wire is connected to the current source, and the current is passed through. When the current value is continuously increased, the composite fiber does not change significantly when the current is less than 10mA. When the current is greater than 10 mA and less th...

specific example 3

[0040] HOCH 2 C≡C-C≡CCH 2 OH was dissolved in tetrahydrofuran to prepare a 10mg / ml diacetylene monomer solution. Then, the carbon nanotube fibers with a diameter of 11 μm were immersed in the diacetylene monomer solution for 20 minutes, and the solvent was volatilized at room temperature after being taken out. Place in a fume hood for 24 hours. A UV lamp with a wavelength of 254 nm was used to irradiate 17 cm away from the fiber for 2 hours to polymerize the diacetylene monomer on the fiber to obtain an orange carbon nanotube / polydiyne composite fiber. Take a section of fiber and fix it on the glass substrate, and connect the two ends with silver glue and gold wire. The gold wire is connected to the current source, and the current is passed through. When the current value is continuously increased, the composite fiber does not change significantly when the current is less than 10mA. When the current is greater than 10 mA and less than 30 mA, the composite fiber turns brown w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com