Mine gas and petrochemical associated gas power generation system and mine gas and petrochemical associated gas utilization method

A technology of power generation system and associated gas, applied in fuel system, gaseous engine fuel, gaseous fuel, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

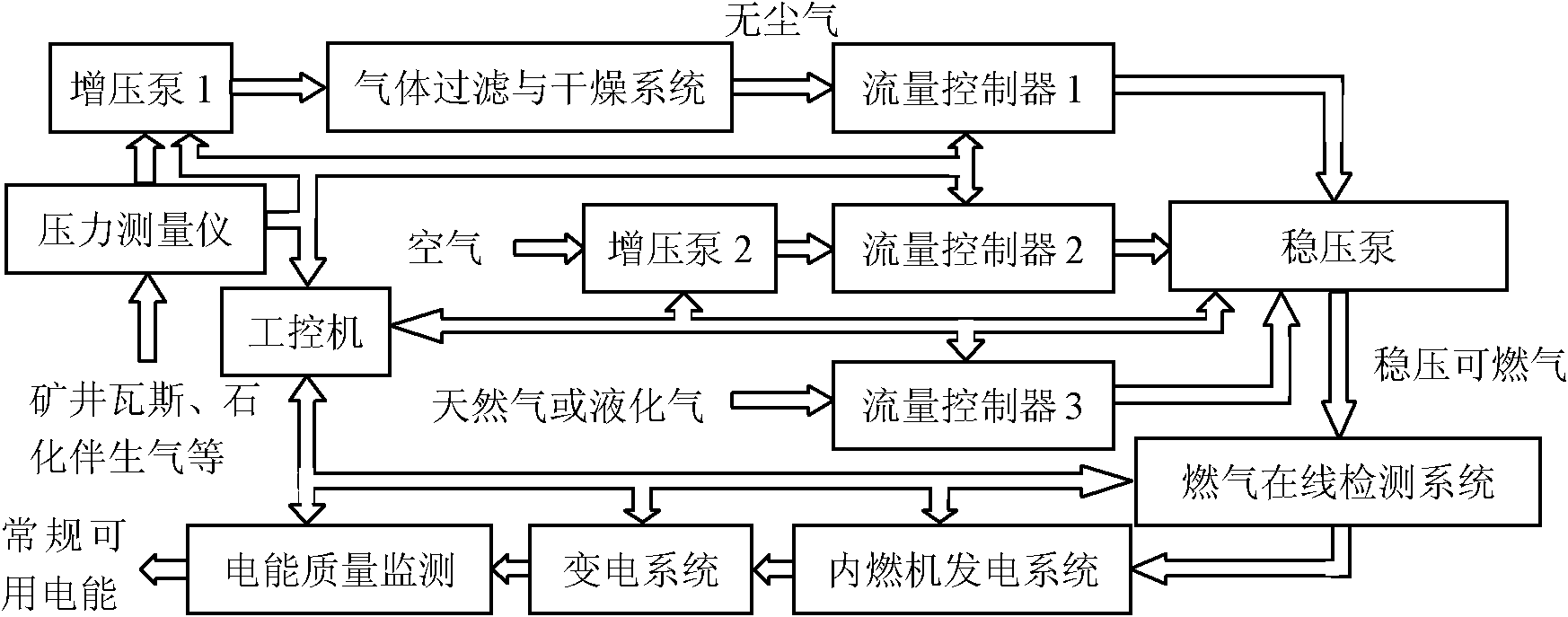

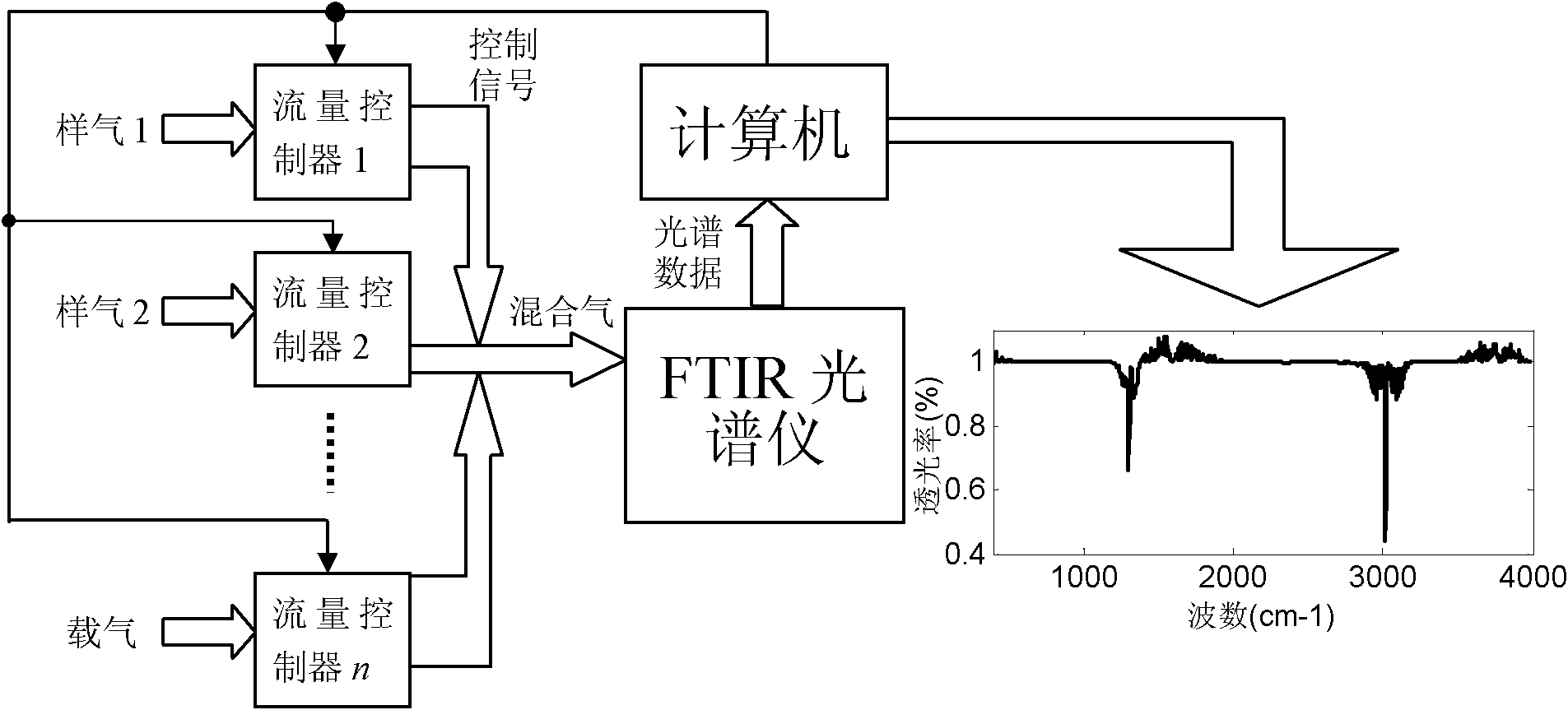

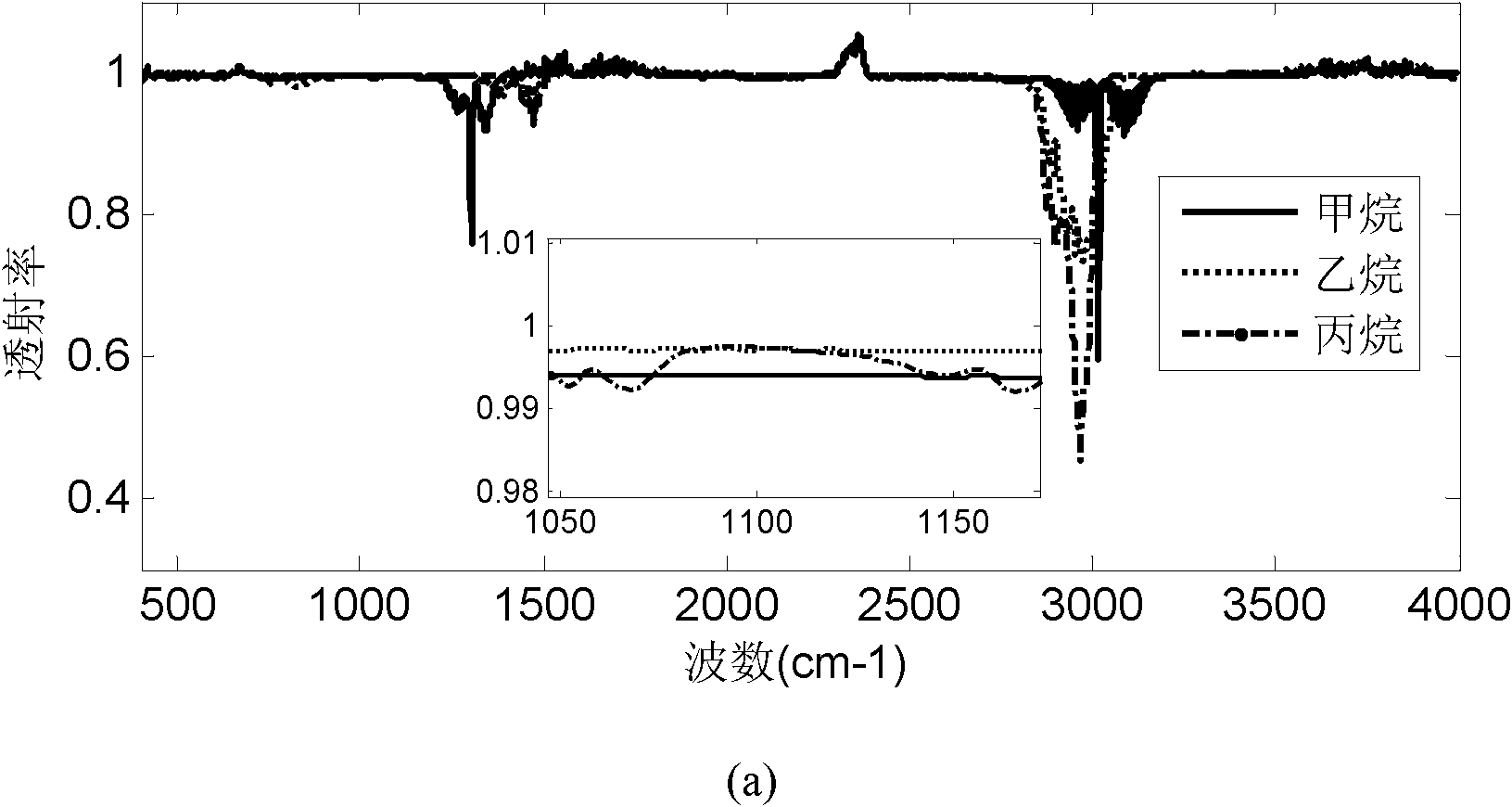

[0018] see figure 1 , 2 , 3, 4 and 5, the mine gas and petrochemical associated gas power generation system consists of hardware and software. The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments given by the inventor. Among them, the associated gas is the tomographic gas in oil and natural gas exploration as an example, and its flow rate is from 1 liter per minute to 10 liters per minute.

[0019] 1. Hardware part

[0020] The hardware part of mine gas and petrochemical associated gas power generation system includes connecting pipelines, pressure measuring instruments, booster pumps, gas filtration and drying systems, natural gas or liquefied gas sources, flow controllers, pressure stabilizing pumps, gas online detection systems, Composed of industrial computer, gas generator and power qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com