Self-aligned spacer multiple patterning methods

A multi-patterning and spacer technology, which is applied in the photoengraving process, instruments, optomechanical equipment and other directions of the pattern surface, which can solve the problems of cost inefficiency and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

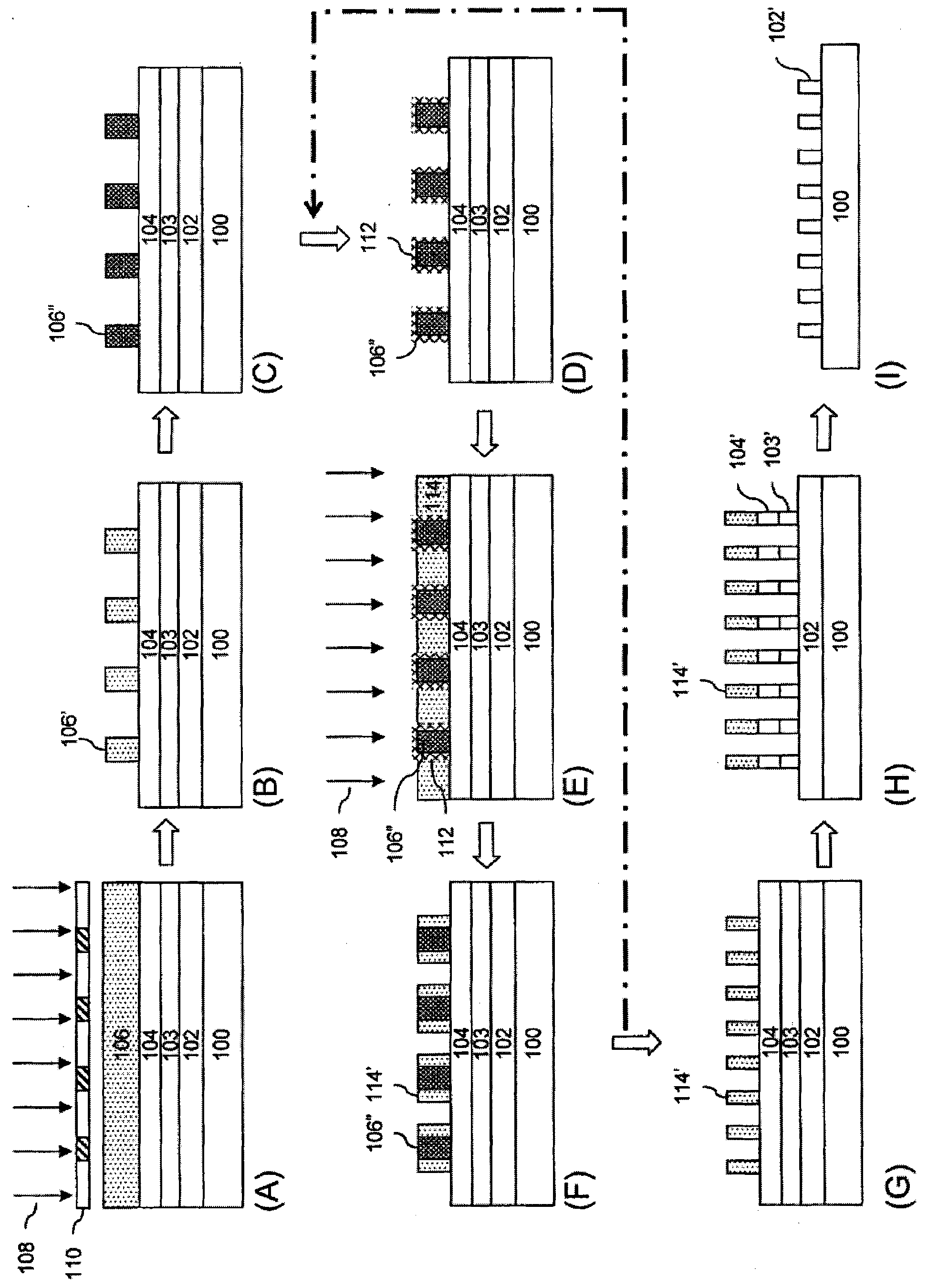

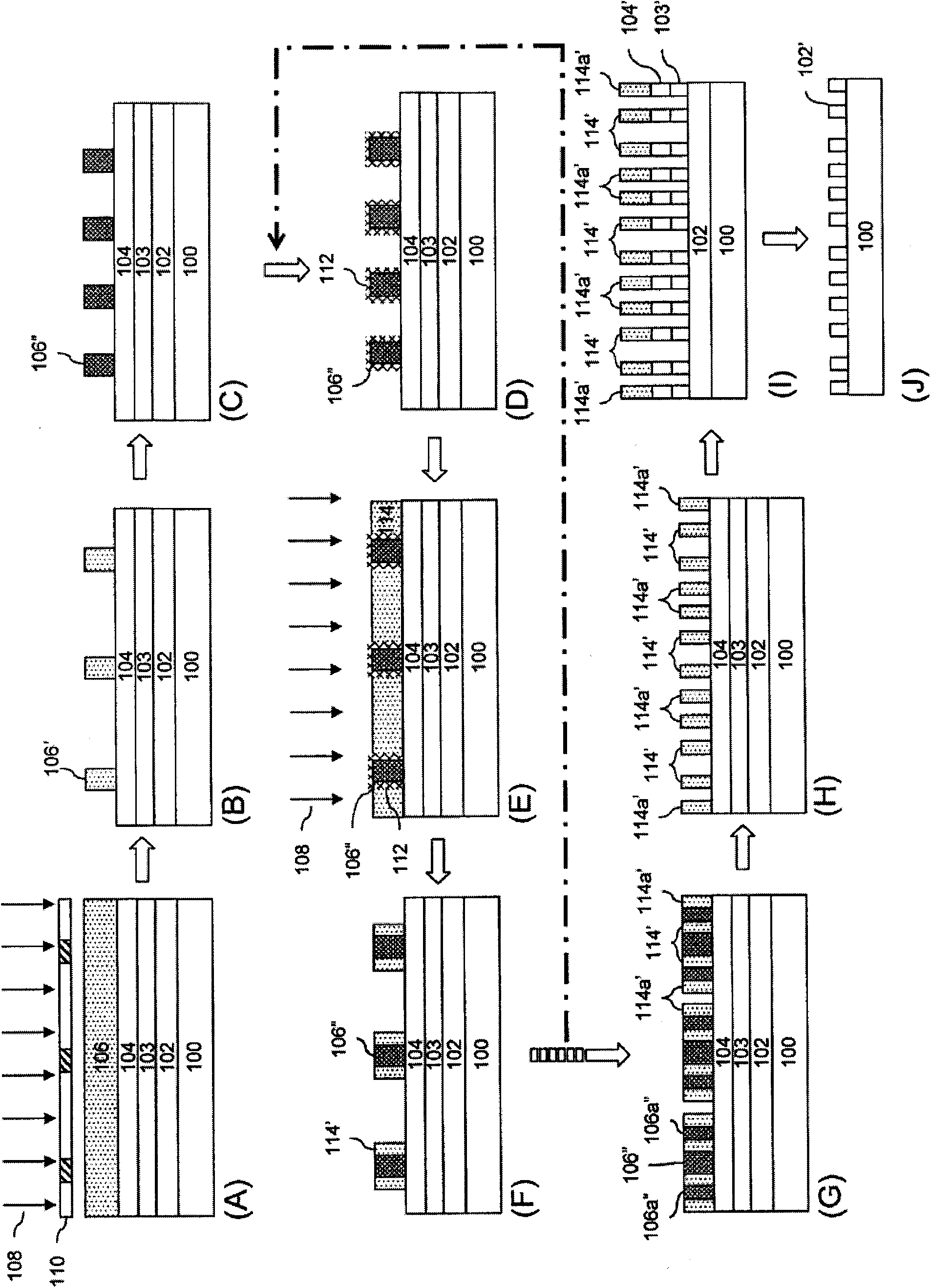

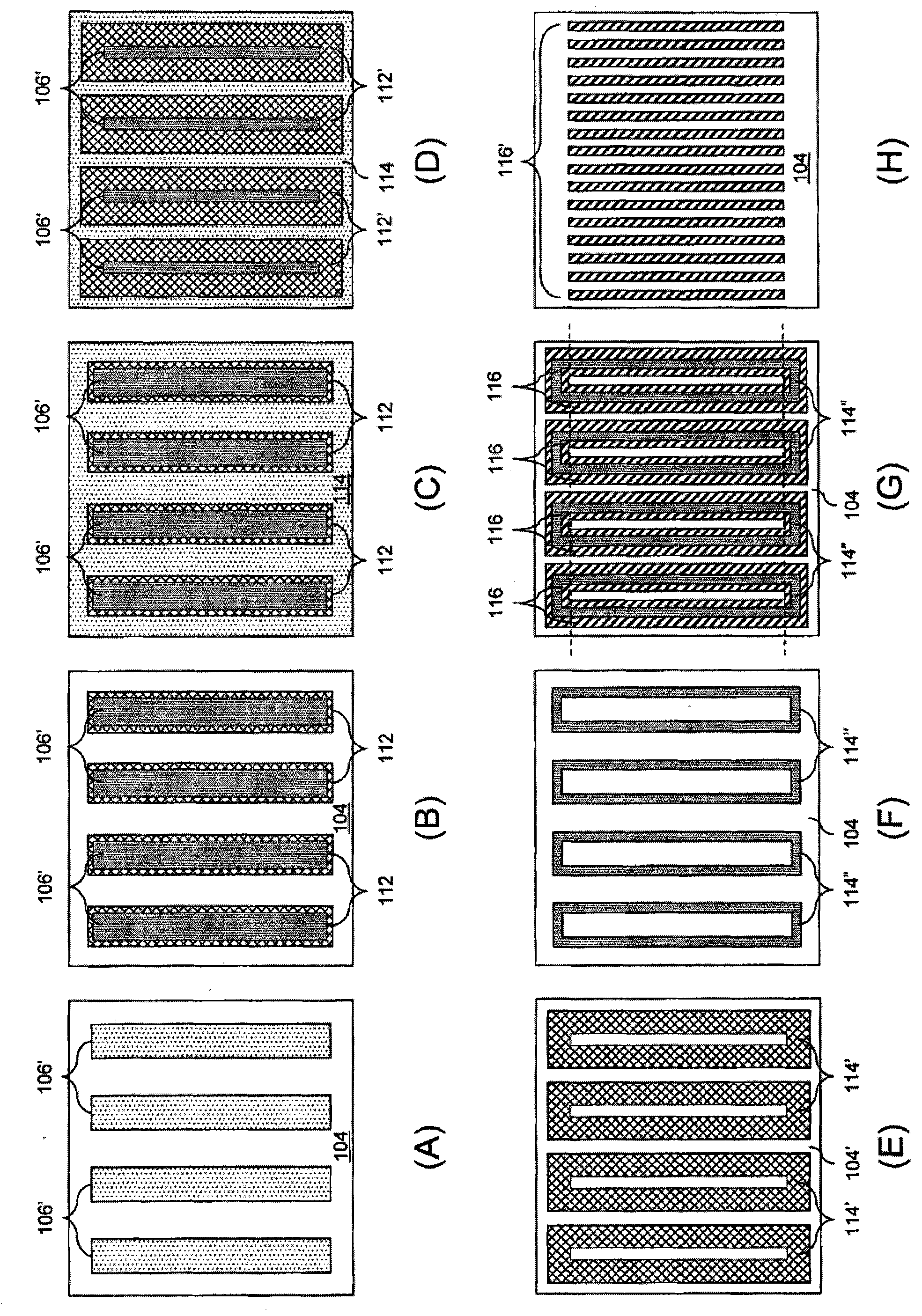

Method used

Image

Examples

Embodiment 1

[0073] L1 photoresist polymer (poly(IAM / α-GBLMA / ODOTMA / HAMA)) synthesis

[0074] 10.51 g of 2-methyl-acrylate 1-isopropyl-adamantyl (IAM), 6.82 g of 2-methyl-acrylate 2-oxo-tetrahydro-furan-3yl ester (α-GBLMA), 6.36 g 2-Methyl-acrylic acid 3-oxo-4,10-dioxo-tricyclo[5.2.1.0 2,6 ] Dec-8-yl ester (ODOTMA) and 6.31 g of 3-hydroxy-adamantyl 2-methyl-acrylate (HAMA) were dissolved in 27 g of tetrahydrofuran (THF). The mixture was degassed by bubbling nitrogen gas for 20 min. A 500 ml ampoule equipped with a condenser, nitrogen gas inlet and mechanical stirrer was charged with 11 g of THF and the solution was warmed to a temperature of 67°C. 5.23 g of dimethyl-2,2-azobisisobutyrate (17 mol % based on the whole monomer) were dissolved in 5 g of THF and filled into an ampoule. The monomer solution was flowed into the reactor at a rate of 16.0 milliliters per hour (mL / h) for 3 hours and 30 minutes. The polymerization mixture was stirred for an additional 30 minutes at 67°C. 5 g of ...

Embodiment 2-18

[0088] The above procedure of Reference Example 1 was repeated except that the ingredients listed in Table 1 below were used instead of TAEA and TERGITOL TMN-6 surfactant.

[0089] Table 1

[0090] Example

[0091] It is expected that spacer structures will form after L2 development.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com