Surface plasmon (SPP)-based large-area interference lithography technology

An interference lithography, large-area technology, applied in the field of micro-nano processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] specific implementation

[0036] The periodic nanowires produced by the method of the present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings:

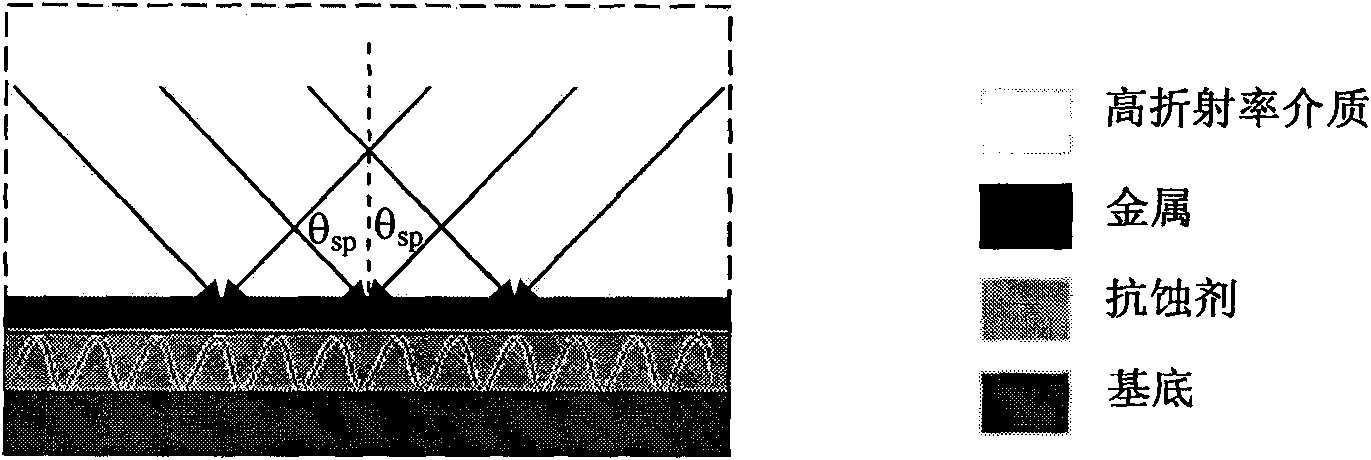

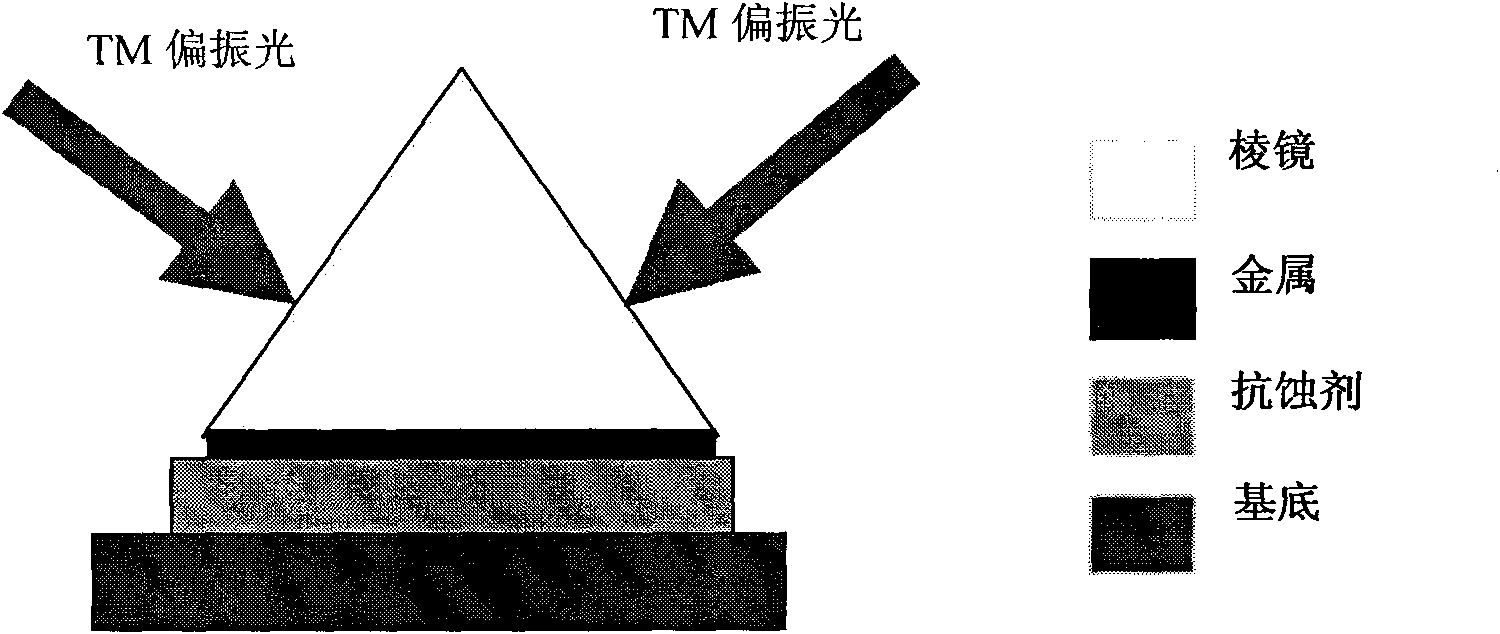

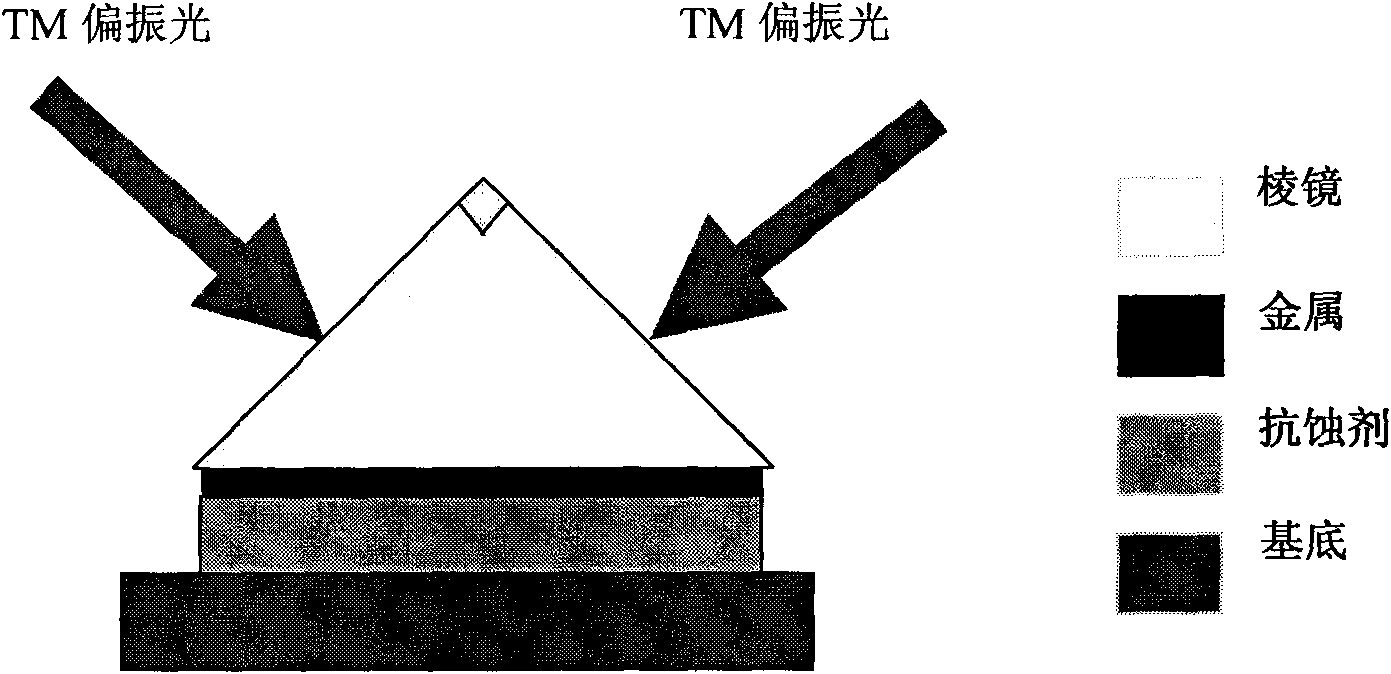

[0037] (1) with Figure 4 For example, make photolithographic dense lines below 65nm.

[0038] Assuming that the incident light source wavelength is 436nm, the refractive index of the equilateral triangular prism is 1.94325 (NLAF36 glass); the metal is silver, and its complex dielectric constant is -8.9170+0.2320i, and the thickness is 40nm; the refractive index of the resist is 1.53 (AZ9200).

[0039] The calculation steps are:

[0040] 1. According to formulas (1) and (2), the resonance angle θ can be calculated sp about 66°;

[0041] 2. According to the formula (4), it can be calculated that the period of the interference fringe Λ = 122nm;

[0042] 3. According to the formula (5), the feature size of the line is R=61nm, which meets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com