Manganese dioxide-silver oxide composite oxide nanowire and preparation method thereof adopting single-walled carbon nanotubes as templates

A technology of single-wall carbon nanotubes and composite oxides, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems that have not been reported, and achieve the effects of low reaction temperature, simple operation, and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

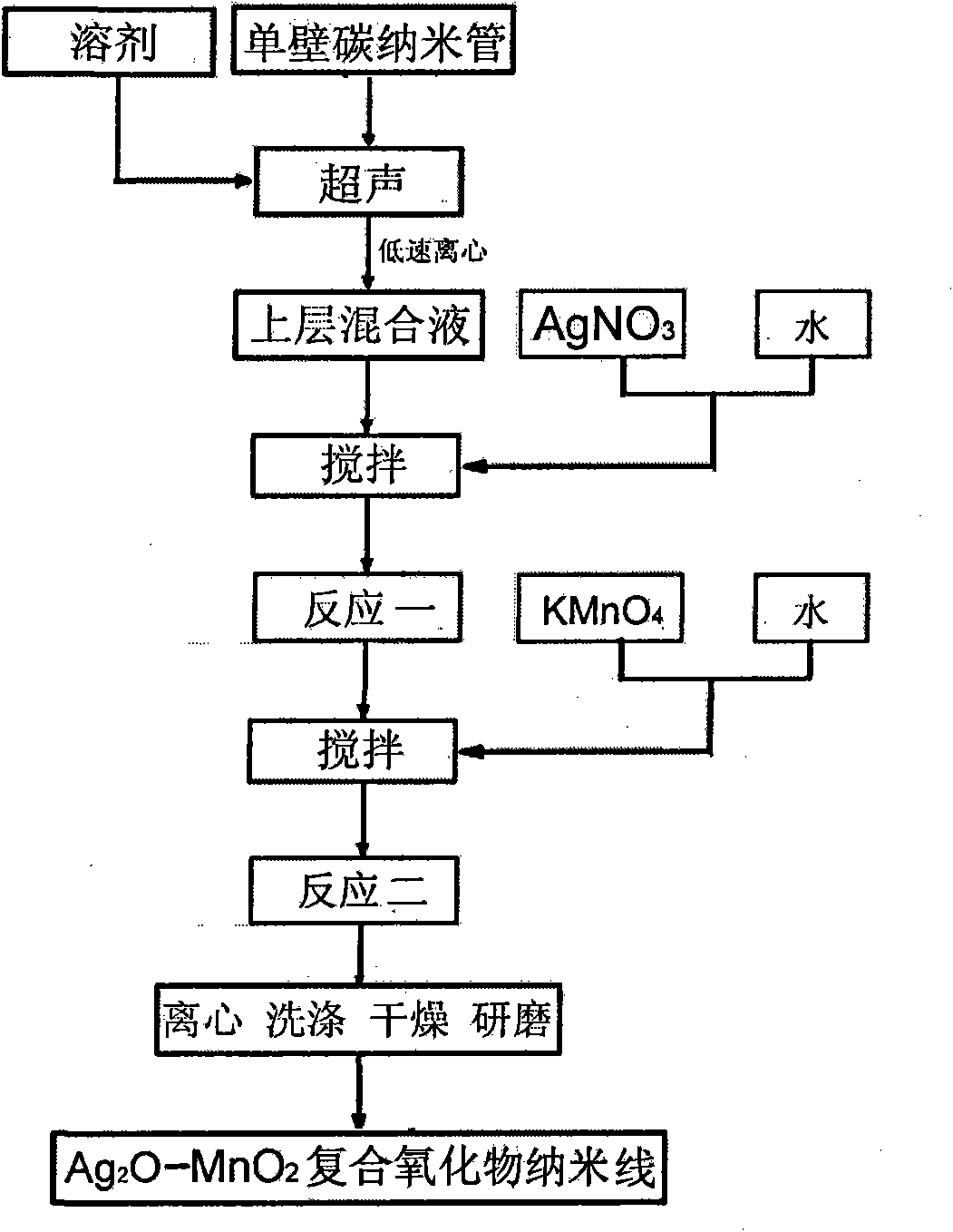

[0031] Step 1: Disperse 10 mg of single-walled carbon nanotubes in 100 mL of N-methylpyrrolidone, and then perform ultrasonic treatment (10 min to 2 h);

[0032] Step 2: Centrifuge the mixture obtained in Step 1 (100-1000rpm), discard the residual solid at the bottom, and take the mixed solution in the upper layer (that is, the suspension formed by dispersing the raw material single-walled carbon nanotubes in N-methylpyrrolidone);

[0033] Step 3: Add 20mgAgNO 3 Dissolve with 7.5mL water to form AgNO 3 aqueous solution;

[0034] Step 4: Incorporate AgNO in Step 3 3 Add the solution to the mixed solution in step 2, stir and react at 25°C for 72 hours, the reaction equation is 2AgNO 3 +2H 2 O→2AgOH+2HNO 3 → Ag 2 O+2HNO 3 +2H 2 O;

[0035] Step 5: 300mg KMnO 4 Dissolve in 5mL water to form KMnO 4 aqueous solution;

[0036] Step 6: KMnO in Step 5 4 Add the solution to the mixed solution in step 4, at 25°C for 48 hours, the reaction equation is 4KMnO 4 +3C+H2 O→4MnO ...

Embodiment 2

[0040] Step 1: Disperse 1 mg of single-walled carbon nanotubes in 100 mL of N-methylpyrrolidone, and then perform ultrasonic treatment (10 min to 2 h);

[0041] Step 2: Centrifuge the mixture obtained in Step 1 (100-1000rpm), discard the residual solid at the bottom, and take the mixed solution in the upper layer (that is, the suspension formed by dispersing the raw material single-walled carbon nanotubes in N-methylpyrrolidone);

[0042] Step 3: Add 6mg AgNO 3 Dissolve with 7.5mL water to form AgNO 3 aqueous solution;

[0043] Step 4: Incorporate AgNO in Step 3 3 Add the solution to the mixed solution in step 2, stir and react at 50°C for 24 hours, the reaction equation is 2AgNO 3 +2H 2 O→2AgOH+2HNO 3 → Ag 2 O+2HNO 3 +2H 2 O;

[0044] Step 5: 50mg KMnO 4 Dissolve in 5mL water to form KMnO 4 aqueous solution;

[0045] Step 6: KMnO in Step 5 4 Add the solution to the mixed solution in step 4, at 5°C for 72 hours, the reaction equation is 4KMnO 4 +3C+H 2 O→4MnO 2...

Embodiment 3

[0048] Step 1: Disperse 5 mg of single-walled carbon nanotubes in 100 mL of N-methylpyrrolidone, and then perform ultrasonic treatment (10 min to 2 h);

[0049] Step 2: Centrifuge the mixture obtained in Step 1 (100-1000rpm), discard the residual solid at the bottom, and take the mixed solution in the upper layer (that is, the suspension formed by dispersing the raw material single-walled carbon nanotubes in N-methylpyrrolidone);

[0050] Step 3: Add 300mgAgNO 3 Dissolve with 7.5mL water to form AgNO 3 aqueous solution;

[0051] Step 4: Incorporate AgNO in Step 3 3 Add the solution to the mixed solution in step 2, stir and react at 80°C for 10 minutes, the reaction equation is 2AgNO 3 +2H 2 O→2AgOH+2HNO 3 → Ag 2 O+2HNO 3 +2H 2 O;

[0052] Step 5: 250mg KMnO 4 Dissolve in 5mL water to form KMnO 4 aqueous solution;

[0053] Step 6: KMnO in Step 5 4 Add the solution to the mixed solution in step 4, at 80°C for 48 hours, the reaction equation is 4KMnO 4 +3C+H 2 O→4M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com