Method for preparing Co-Ni-Mn ternary anode materials by microwave sintering

A cathode material and microwave sintering technology, which is applied in the field of preparing lithium-ion battery manganese-cobalt-nickel ternary cathode materials by microwave sintering, can solve problems such as high cost and poor performance, and achieve low production cost, reduced synthesis time, and simple process control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

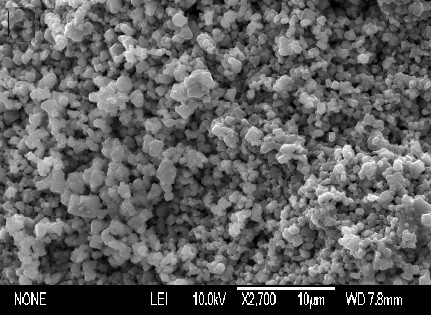

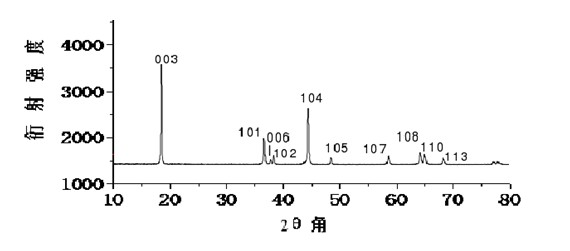

[0031] Embodiment one: Li-ion battery ternary cathode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 preparation method

[0032] (1) 5800 g of MnO 2 , 6100g Ni(OH) 2 and 4900 grams of CoO are added to the mixer, and stirred evenly to obtain MnO 2 , Ni(OH) 2 Mixture A with CoO;

[0033] (2) Dissolve 2,000 grams of glucose in 15,200 mL of pure water, and stir evenly to obtain an aqueous solution of glucose;

[0034] (3) 7500 grams of Li 2 CO 3 Add to the above aqueous glucose solution, stir evenly to obtain mixture B;

[0035] (4) Add mixture B to mixture A and stir evenly to obtain a paste precursor;

[0036] (5) Add the paste precursor into the silicon carbide crucible, put the silicon carbide crucible into an industrial microwave oven, raise the temperature to 780°C at a rate of 10°C per minute, and keep it for 20 minutes to obtain the positive electrode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 .

[0037] (where Li 2 CO 3 Molecular weight 73.80, MnO 2 Molecular weight 86.9...

Embodiment 2

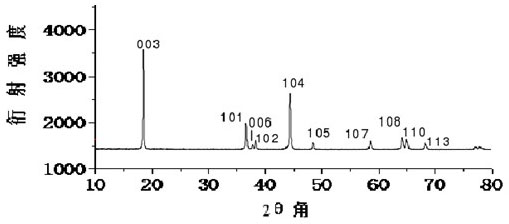

[0039] Embodiment two: Li-ion battery ternary cathode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 preparation method

[0040] (1) 5600 g of MnO 2 , 6000g Ni(OH) 2 Add 4800 grams of CoO to a mixer (or ball mill) and mix, and stir evenly to obtain mixture A;

[0041] (2) Dissolve 3,800 grams of sucrose in 19,000 mL of pure water, and stir evenly to obtain an aqueous solution of sucrose;

[0042] (3) 8400 g of LiOH·H 2 O is added to the sucrose aqueous solution and stirred evenly to obtain the mixture B;

[0043] (4) Mix the mixtures A and B, and stir evenly to obtain a paste precursor;

[0044] (5) Put the paste precursor into a kraft paper container, put the kraft paper container into an industrial microwave oven, raise the temperature to 820 °C at a rate of 8 °C per minute, and keep it for 40 minutes to obtain the positive electrode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 .

[0045] (where LiOH·H 2 O molecular weight 41.96, MnO 2 Molecular weight 86.94, Ni(OH) 2 The mole...

Embodiment 3

[0047] Embodiment three: Li-ion battery ternary cathode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 preparation method

[0048] (1) 5600 g of MnO 2 , 5200g Ni 2 o 3 and 5200 g Co 2 o 3 Add a ball mill and mix evenly to obtain mixture A;

[0049] (2) Dissolve 2,000 grams of glucose and 1,000 grams of oxalic acid in 22,000 mL of purified water, and stir evenly to obtain an aqueous solution of glucose and oxalic acid;

[0050] (3) 7500 grams of Li 2 CO 3 Add to the above aqueous solution, stir evenly to obtain mixture B;

[0051] (4) Mix the mixtures A and B, and stir evenly to obtain a paste precursor;

[0052] (5) Put the paste precursor into a kraft paper container, put the kraft paper container into an industrial microwave oven, raise the temperature to 750 °C at a rate of 6 °C per minute, and keep it for 30 minutes to obtain the positive electrode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 .

[0053] This example can prepare about 19kg LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com