Medicinal low-temperature-resistant toughening anti-gamma ray impact-resistant transparent polypropylene material and preparation method thereof

A transparent polypropylene, gamma ray technology, applied in the field of polypropylene materials, can solve the problems affecting the toughness of the material, the easy rupture of the syringe, the breakage of the molecular chain, etc., to achieve excellent toughness and impact resistance, improve gamma ray resistance, Excellent effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

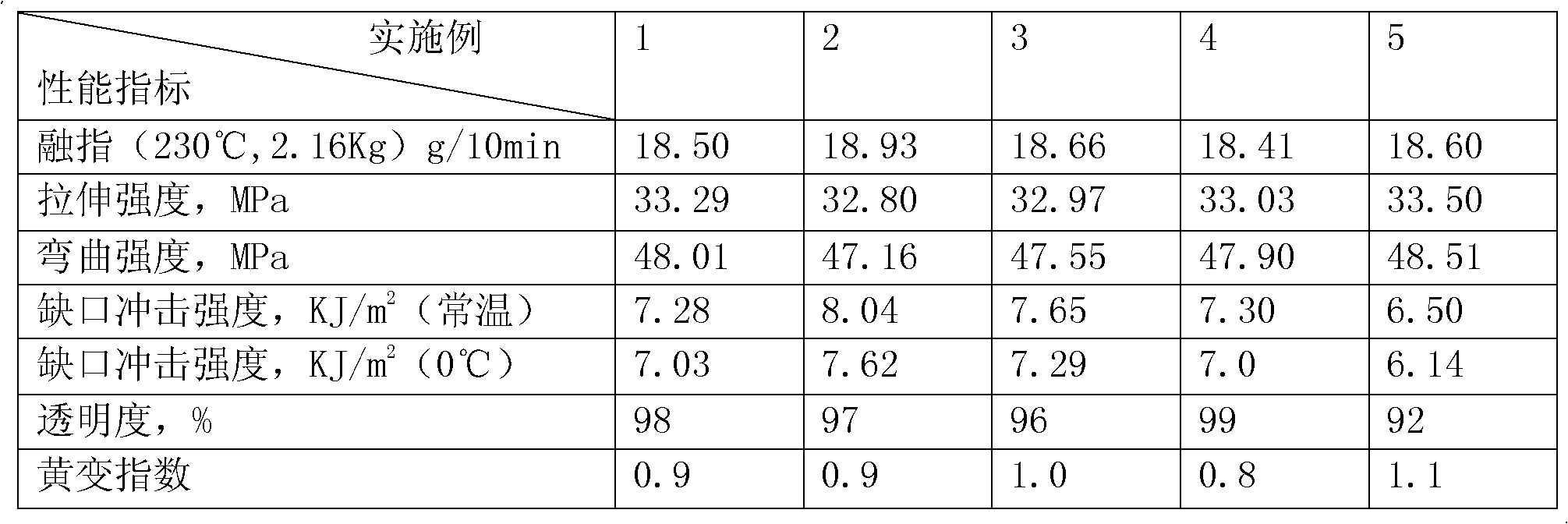

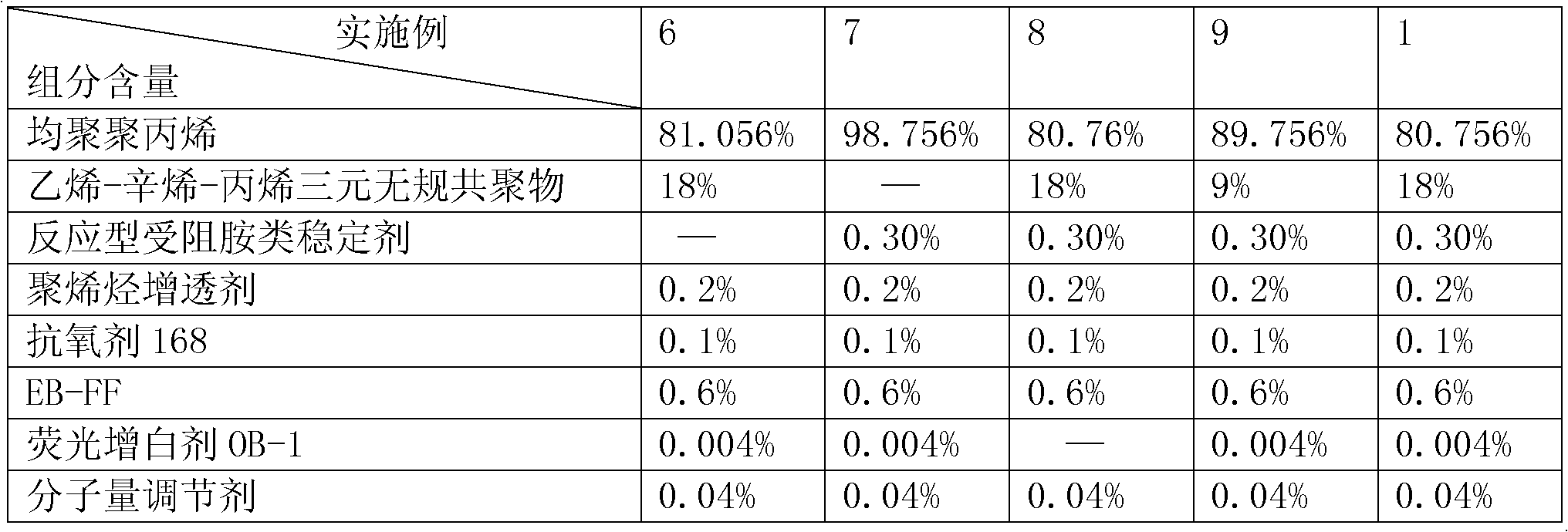

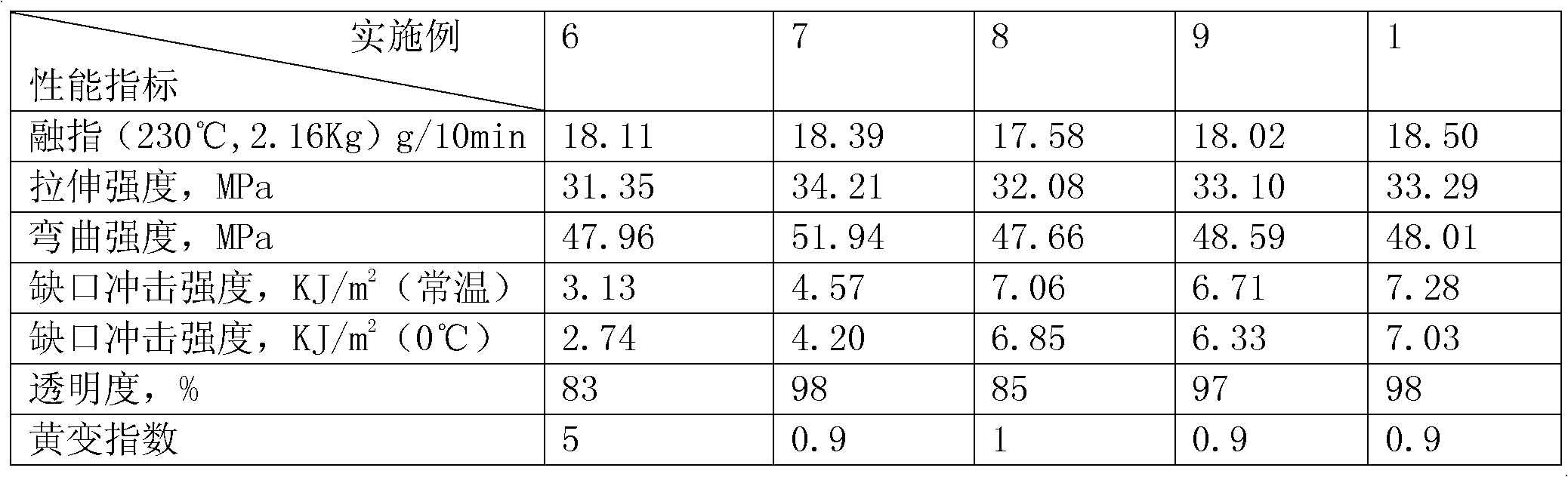

Embodiment 1

[0056] A medical low-temperature-resistant, toughened, gamma-ray-resistant, and impact-resistant transparent polypropylene material, the weight percentage of which is composed of:

[0057] Homopolypropylene 75.856%

[0058] Ethylene-octene-propylene terpolymer random copolymer 20%

[0059] Reactive hindered amine stabilizer 3.2%

[0060] Polyolefin antireflection agent 0.2%

[0061] Antioxidant 168 0.1%

[0062] EB-FF 0.6%

[0063] Optical brightener OB-1 0.004%

[0064] Di-tert-butyl peroxide 0.04%

[0065] Among them, the melt flow rate of homopolypropylene is 4g / 10min (230°C, 2.16Kg), and the notched impact strength is 6KJ / m2.

[0066] The melt flow rate of ethylene-octene-propylene ternary random copolymer is 1.0g / 10min (230 ℃, 2.16Kg), and the notched impact strength is 28KJ / m2; Described ethylene-octene-propylene terpolymer has no The ethylene content in the conventional copolymer is 6%, and the octene content is 14%.

Embodiment 2

[0068] A medical low-temperature-resistant, toughened, gamma-ray-resistant, and impact-resistant transparent polypropylene material, the weight percentage of which is composed of:

[0069] Homopolypropylene 70.834%

[0070] Ethylene-octene-propylene terpolymer random copolymer 22%

[0071] Reactive hindered amine stabilizer 5.26%

[0072] Polyolefin antireflection agent 0.3%

[0073] Antioxidant 168 1.2%

[0074] EB-FF 0.3%

[0075] Optical brightener OB-1 0.006%

[0076] Di-tert-butyl peroxide 0.1%

[0077] Among them, the melt flow rate of homopolypropylene is 2g / 10min (230°C, 2.16Kg), and the notched impact strength is 8KJ / m 2 ;

[0078] The melt flow rate of ethylene-octene-propylene terpolymer is 0.1g / 10min (230℃, 2.16Kg), and the notched impact strength is 28KJ / m 2 ;

[0079] The ethylene content in the ethylene-octene-propylene terpolymer is 10%, and the octene content is 20%.

Embodiment 3

[0081] A medical low-temperature-resistant, toughened, gamma-ray-resistant, and impact-resistant transparent polypropylene material, the weight percentage of which is composed of:

[0082] Homopolypropylene 71.445%

[0083] Ethylene-octene-propylene terpolymer random copolymer 26%

[0084] Reactive hindered amine stabilizer 1.36%

[0085] Polyolefin antireflection agent 0.23%

[0086] Antioxidant 168 0.5%

[0087] EB-FF 0.4%

[0088] Optical brightener OB-1 0.005%

[0089] Di-tert-butyl peroxide 0.06%

[0090] Among them, the melting range of homopolypropylene is 6g / 10min (230°C, 2.16Kg), and the notched impact strength is 5KJ / m2;

[0091] Ethylene-octene-propylene terpolymer random copolymer, melting range is 2g / 10min (230℃, 2.16Kg), notched impact strength is 25KJ / m2;

[0092] The ethylene content in the ethylene-octene-propylene terpolymer is 20%, and the octene content is 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com