Preparation method of cast abrasion-resistant corrosion-resistant zinc aluminum alloy

A zinc-aluminum alloy, corrosion-resistant technology, applied in the field of new zinc-based bearing and bushing materials, can solve problems such as temperature rise, low tensile strength, limited application, etc., and achieve the effect of broad social application prospects and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

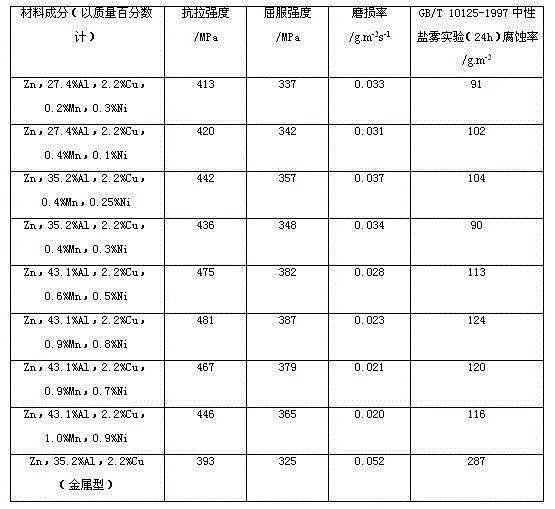

Examples

Embodiment 1

[0020] A method for preparing a wear-resistant and corrosion-resistant zinc-aluminum alloy material comprises the following steps:

[0021] (1) First heat the box-type medium-temperature resistance furnace to 750°C, and then put the crucibles containing aluminum ingots, aluminum-copper master alloys, aluminum-manganese master alloys and aluminum-nickel master alloys into the box-type medium-temperature resistance furnace respectively, and wait for them to After all melting, the temperature is lowered to 700°C, and then the zinc ingot is put into it. After 30 minutes of heat preservation, the slag is removed and a covering agent is added. The covering agent is a mixture of 50% by mass NaCl and 50% by mass of KCl, and then Degas and remove impurities with hexachloroethane to obtain molten metal;

[0022] (2) Electromagnetic stirring equipment is used for electromagnetic stirring blank making. The equipment includes a voltage regulating transformer and a stirring device. The rate...

Embodiment 2

[0025] A method for preparing a wear-resistant and corrosion-resistant zinc-aluminum alloy material comprises the following steps:

[0026] (1) First heat the box-type medium-temperature resistance furnace to 750°C, and then put the crucibles containing aluminum ingots, aluminum-copper master alloys, aluminum-manganese master alloys and aluminum-nickel master alloys into the box-type medium-temperature resistance furnace respectively, and wait for them to After all melting, the temperature is lowered to 700°C, and then the zinc ingot is put into it. After 30 minutes of heat preservation, the slag is removed and a covering agent is added. The covering agent is a mixture of 50% by mass NaCl and 50% by mass of KCl, and then Degas and remove impurities with hexachloroethane to obtain molten metal;

[0027] (2) Electromagnetic stirring equipment is used for electromagnetic stirring blank making. The equipment includes a voltage regulating transformer and a stirring device. The rate...

Embodiment 3

[0030] A method for preparing a wear-resistant and corrosion-resistant zinc-aluminum alloy material comprises the following steps:

[0031] (1) First heat the box-type medium-temperature resistance furnace to 750°C, and then put the crucibles containing aluminum ingots, aluminum-copper master alloys, aluminum-manganese master alloys and aluminum-nickel master alloys into the box-type medium-temperature resistance furnace respectively, and wait for them to After all melting, the temperature is lowered to 700°C, and then the zinc ingot is put into it. After 30 minutes of heat preservation, the slag is removed and a covering agent is added. The covering agent is a mixture of 50% by mass NaCl and 50% by mass of KCl, and then Degas and remove impurities with hexachloroethane to obtain molten metal;

[0032] (2) Electromagnetic stirring equipment is used for electromagnetic stirring blank making. The equipment includes a voltage regulating transformer and a stirring device. The rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com