Method for preparing density-adjustable TiO2 nanorod array

A nanorod array and nanorod technology, which is applied in the field of preparation of TiO2 nanorod arrays, can solve the problems that the density of nanorod arrays has not been fully controllable, and achieve controllable photocatalytic performance, simple and easy preparation methods, photoelectric performance controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] 1) Dissolve tetra-n-butyl titanate, water and acetylacetone at a molar ratio of 1:1:0.3 in ethanol, then add polyvinylpyrrolidone to form a titanium concentration of 0.1mol / L and a polyvinylpyrrolidone concentration of 30mg / L Titanium dioxide precursor sol;

[0016] 2) Spin-coat the titanium dioxide precursor sol onto the glass substrate at a speed of 6000rpm at 20°C for 35s to form a titanium dioxide precursor nano-dot array sol film on the substrate, and then put the glass substrate into the muffle Heat treatment in a furnace at 100°C;

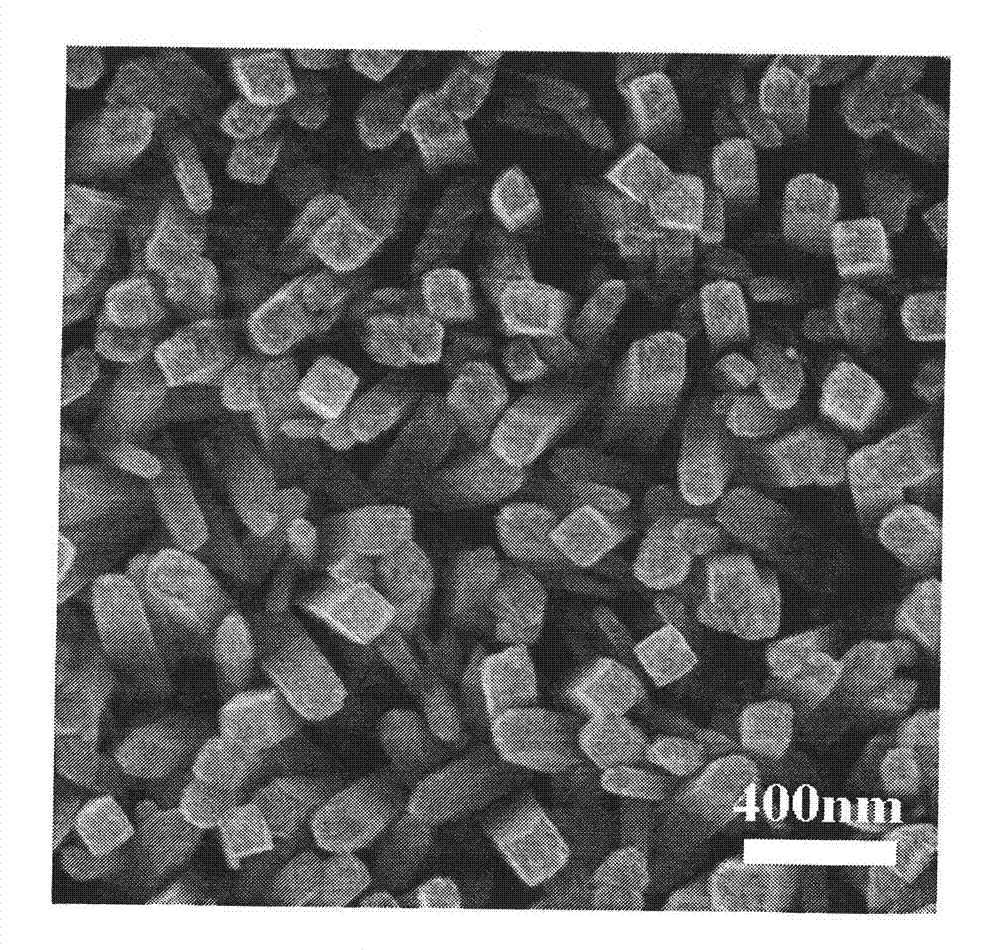

[0017] 3) Add 0.005M tetrabutyl titanate into 0.5M hydrochloric acid solution, stir until a stable solution is formed, and transfer to a 100mL hydrothermal kettle. The heat-treated glass substrate is placed in a hydrothermal kettle obliquely. The hydrothermal temperature is 80°C, and the hydrothermal time is 2h. The present invention obtains TiO on the glass substrate 2 Nanorod array structure, the diameter of nanorods is 10nm, an...

example 2

[0019] 1) Dissolve tetra-n-butyl titanate, water and acetylacetone at a molar ratio of 1:1.1:0.4 in ethanol, then add polyvinylpyrrolidone to form a titanium concentration of 0.2mol / L and a polyvinylpyrrolidone concentration of 40mg / L Titanium dioxide precursor sol;

[0020] 2) The titania precursor sol was spin-coated onto the ITO substrate at a speed of 6500rpm at 15°C for 30s to form a titania precursor nano-dot array sol film on the ITO substrate, and then put the substrate into the muffle Heat treatment at 400°C in a furnace;

[0021] 3) Add 0.01M titanium tetrachloride to 0.9M nitric acid solution, stir until a stable solution is formed, and transfer to a 100mL hydrothermal kettle. After heat treatment, the substrate is placed in a hydrothermal kettle obliquely. The hydrothermal temperature is 110°C, and the hydrothermal time is 1.5h. The present invention obtains TiO on the ITO substrate 2 Nanorod array structure, the diameter of nanorods is 42nm, and the density is...

example 3

[0023] 1) Dissolve tetra-n-butyl titanate, water and acetylacetone at a molar ratio of 1:1.2:0.35 in ethanol, then add polyvinylpyrrolidone to form a titanium concentration of 0.3mol / L and a polyvinylpyrrolidone concentration of 60mg / L Titanium dioxide precursor sol;

[0024] 2) The titania precursor sol was spin-coated onto the silicon substrate at a speed of 7000rpm at 10°C for 40s to form a titania precursor nanodot array sol film on the silicon substrate, and then the FTO substrate was placed in the Heat treatment at 600°C in a Furnace;

[0025] 3) Add 0.02M titanium sulfate to 1.3M hydrochloric acid solution, stir until a stable solution is formed, and transfer to a 100mL hydrothermal kettle. After the heat treatment, the FTO substrate was placed in a hydrothermal kettle obliquely. The hydrothermal temperature is 140°C, and the hydrothermal time is 0.5h. The present invention obtains TiO on the silicon substrate 2 Nanorod array structure, the diameter of nanorods is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com