Metal-imitated high-gloss ABS (Acrylonitrile Butadiene Styrene) alloy and preparation method thereof

A high-gloss, metal-like technology, applied in the field of polymer materials, can solve the problems of large market and no high-gloss ABS alloy, and achieve consistent performance, uniform color, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

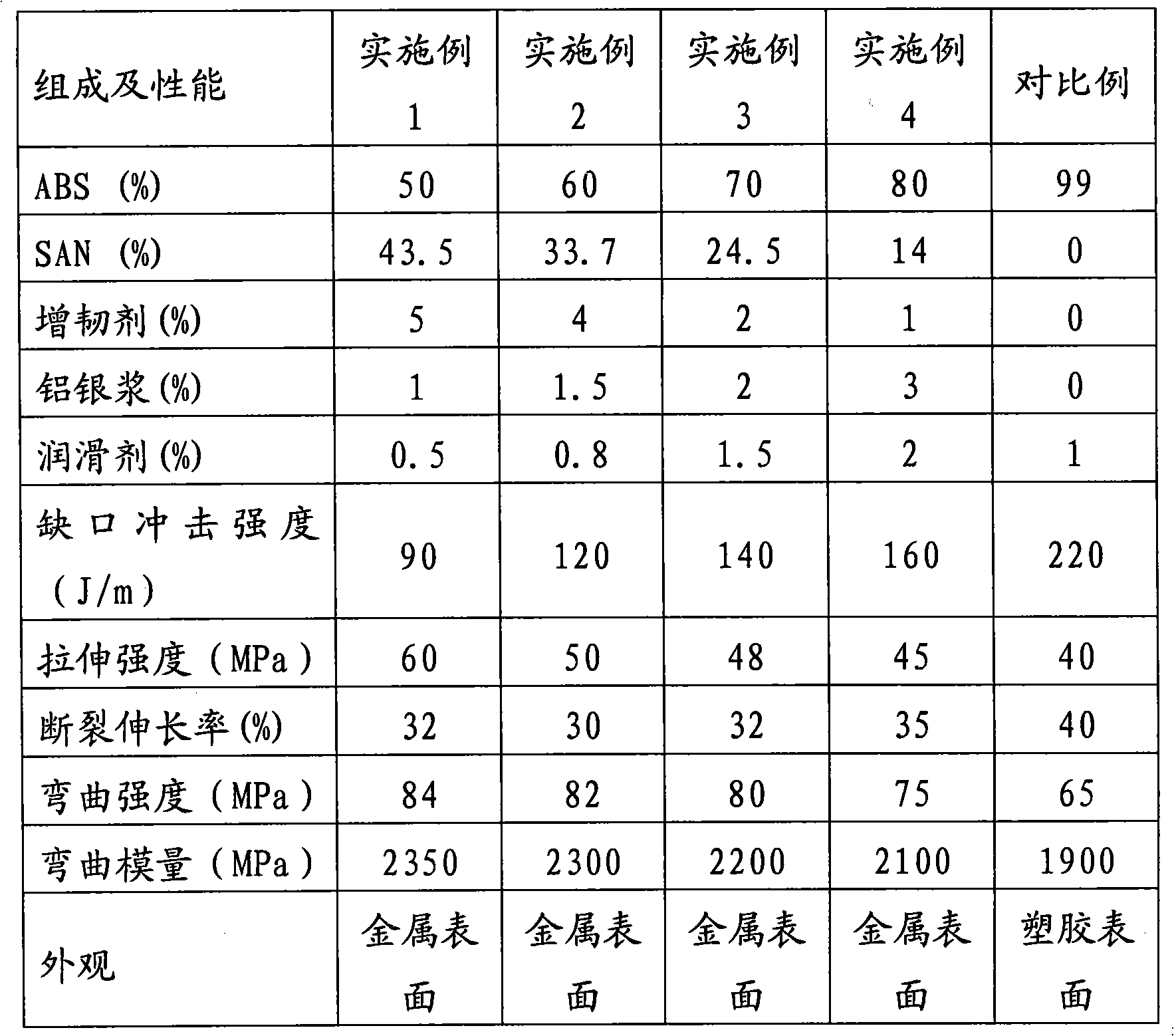

Examples

preparation example Construction

[0027] A method for preparing the above-mentioned high-gloss ABS alloy includes:

[0028] Step 1: The content of polyacrylonitrile-butadiene-styrene 50-80%, polyacrylonitrile-styrene 14-43.5%, toughening agent 1-5%, aluminum silver paste 1-3%, Lubricant 0.5~2% Weigh each component;

[0029] Step 2: Add the components weighed in step 1 to a low-speed mixer and mix;

[0030] Step 3: Add the mixture material obtained in step 2 to a twin-screw extruder, melt and extrude, and pelletize; the process conditions are: temperature in the first zone is 185℃~190℃; temperature in the second zone is 190℃~195℃; temperature in the third zone 200℃~205℃; four zone temperature 200℃~210℃; five zone temperature 205℃~210℃; six zone temperature 200℃~215℃; seven zone temperature 210℃~215℃; machine head temperature 215℃~225℃ ; The residence time is 2 to 3 minutes, the pressure is 10 to 15 MPa, the screw speed is 280 to 350 revolutions per minute, the feeding frequency is 20 to 30 Hz, and the vacuum degree ...

Embodiment 1

[0034] The metal-like high-gloss ABS alloy in this embodiment is composed of the following components by weight percentage: ABS 50%, SAN 43.5%, toughening agent 5%, aluminum silver paste 1%, and lubricant 0.5%;

[0035] The preparation method is as follows:

[0036] Weigh the above weight percentages of each component, and add them to a low-speed mixer to mix, add the mixed materials to the hopper of the twin-screw extruder, melt and blend, extrude and granulate into ABS alloy; The conditions are: temperature in zone one is 185℃; temperature in zone two is 195℃; temperature in zone three is 200℃; temperature in zone four is 210℃; temperature in zone five is 210℃; temperature in zone six is 215℃; temperature in zone seven is 215℃; machine head temperature is 220℃ ; The residence time is 2min, the pressure is 15MPa, the screw speed is 280 rpm, the feeding frequency is 20Hz, and the vacuum degree is -0.05MPa.

Embodiment 2

[0038] The metal-like high-gloss ABS alloy in this embodiment is composed of the following components by weight percentage: ABS 60%, SAN 33.7%, toughening agent 4%, aluminum silver paste 1.5%, lubricant 0.8%;

[0039] The preparation method is as follows:

[0040] Weigh the above weight percentages of each component, and add them to a low-speed mixer to mix, add the mixed materials to the hopper of the twin-screw extruder, melt and blend, extrude and granulate into ABS alloy; The conditions are: temperature in zone one is 185℃; temperature in zone two is 200℃; temperature in zone three is 200℃; temperature in zone four is 210℃; temperature in zone five is 205℃; temperature in zone six is 215℃; temperature in zone seven is 215℃; machine head temperature is 220℃ ; The residence time is 3min, the pressure is 10MPa, the screw speed is 350 rpm, the feeding frequency is 30Hz, and the vacuum degree is -0.03MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com