Epoxy bitumen material for highway and road bridge and preparation method thereof

A technology of epoxy asphalt materials and highways, applied in building insulation materials, roads, roads, etc., can solve the problems of long reaction time, low bending strength, small elongation, etc., and achieve strong performance adjustability and short production cycle , the effect of high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

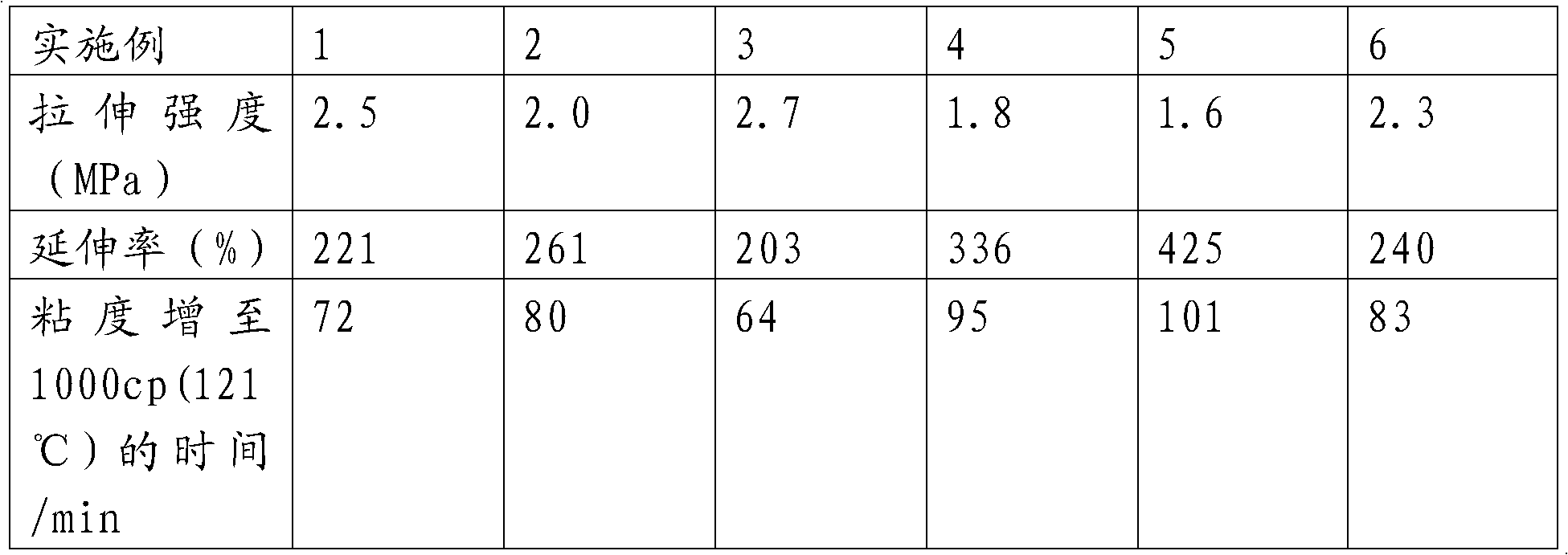

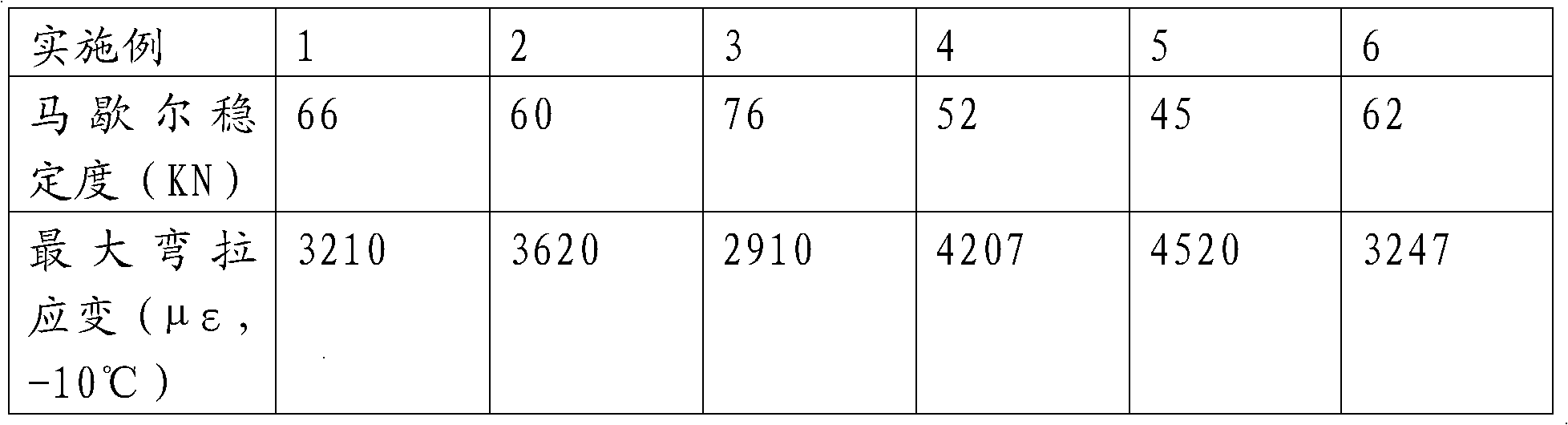

[0023] Example 1: Add 30 parts of succinic acid, 25 parts of adipic acid, 20 parts of polyazelaic anhydride, 0.5 parts of maleic anhydride, 10 parts of tung oilic anhydride and 45 parts of methyltetrahydrophthalic anhydride to 300 parts of asphalt at 150°C (Asphalt place of origin: Koch, Ezhou, Hubei), stir evenly until the system viscosity is almost uniform, add 196 parts of tung oil modified epoxy resin, stir until the system viscosity is uniform, then add 200 parts of B part CYD-128 type epoxy resin, Mix evenly, make the epoxy asphalt material that expressway of the present invention and road bridge are used; Mix in stone material again, compact, heat preservation 5hr, prepare epoxy asphalt concrete, also can not mix in stone material, directly as pavement bonding layer material . The performance of the material itself and the performance of the prepared epoxy asphalt concrete are shown in Table 1 and Table 2.

Embodiment 2

[0024] Example 2: Add 15 parts of oxalic acid, 65 parts of succinic acid, 10 parts of tung oil anhydride and 40 parts of methyltetrahydrophthalic anhydride to 300 parts of asphalt at 140°C (place of asphalt origin: Keshi, Ezhou, Hubei), and stir evenly , until the system viscosity is almost uniform, add 250 parts of tung oil modified epoxy resin, stir until the system viscosity is uniform, then add 200 parts of E-44 type epoxy resin in part B, mix uniformly, and make the highway and road bridge of the present invention Epoxy asphalt material used; then mixed with stones, compacted, and kept warm for 5 hours to prepare epoxy asphalt concrete, or not mixed with stones, directly used as the road surface bonding layer material. The performance of the material itself and the performance of the prepared epoxy asphalt concrete are shown in Table 1 and Table 2.

Embodiment 3

[0025] Example 3: 10 parts of oxalic acid, 20 parts of adipic acid, 20 parts of tung oil anhydride, 50 parts of methyltetrahydrophthalic anhydride and 0.1 part of diethylenetriamine were added to 300 parts of asphalt at 140°C (place of asphalt origin: Ezhou, Hubei Coriolis), stir evenly until the system viscosity is almost uniform, add 150 parts of tung oil modified epoxy resin, stir until the system viscosity is uniform, then add 200 parts of CYD-014 type epoxy resin in part B, mix uniformly, and obtain this product Invented epoxy asphalt material for highways and road bridges; then mixed with stones, compacted, and kept warm for 5 hours to prepare epoxy asphalt concrete, or not mixed with stones, directly used as road surface bonding layer materials. The performance of the material itself and the performance of the prepared epoxy asphalt concrete are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com