Insensitive electric igniter for nuclear blast valve

A technology of electric igniter and blasting valve, which is applied in the field of pyrotechnics, can solve the problems that electric igniters cannot adapt to the working environment of nuclear power units, achieve good insulation performance and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

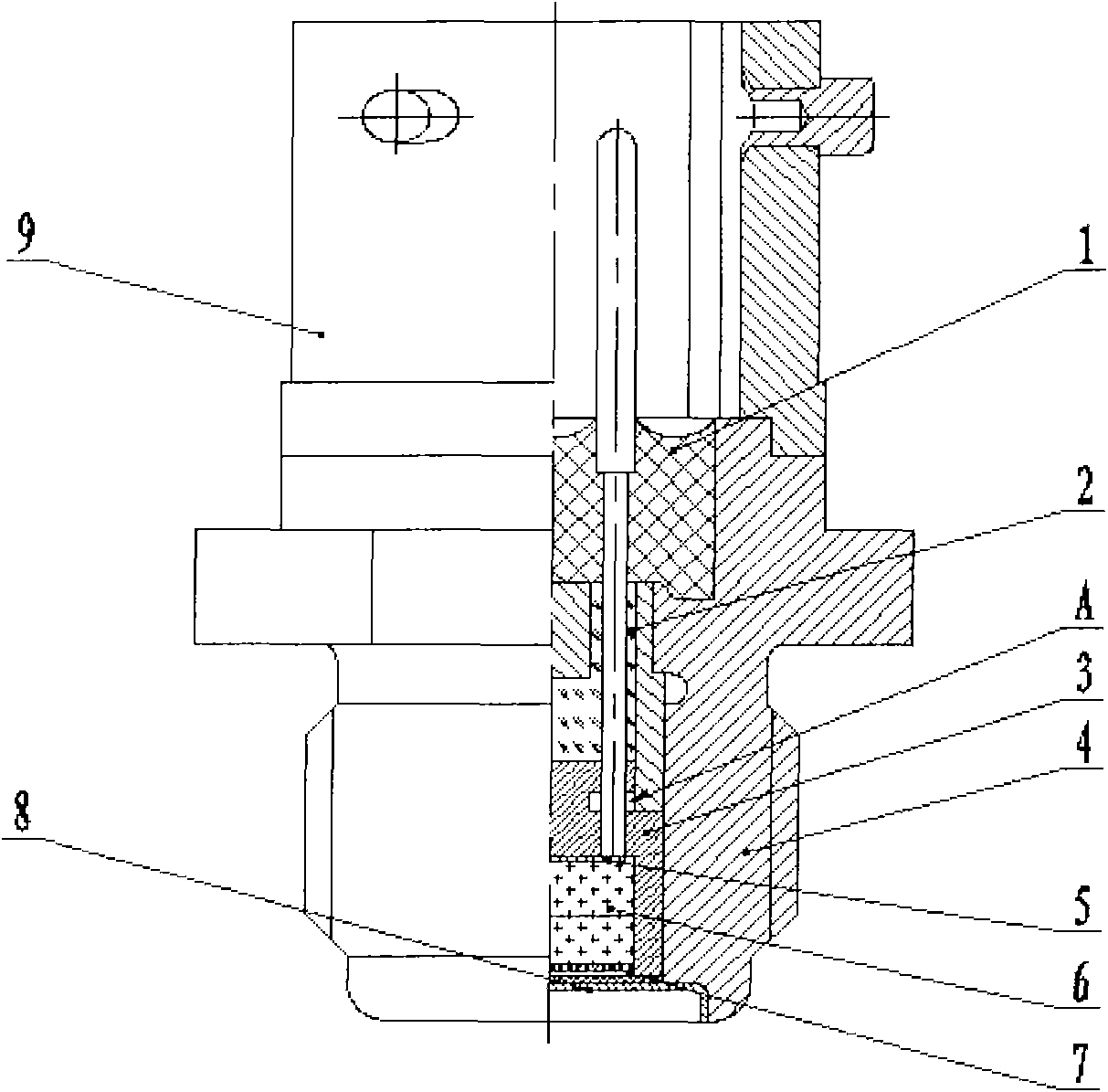

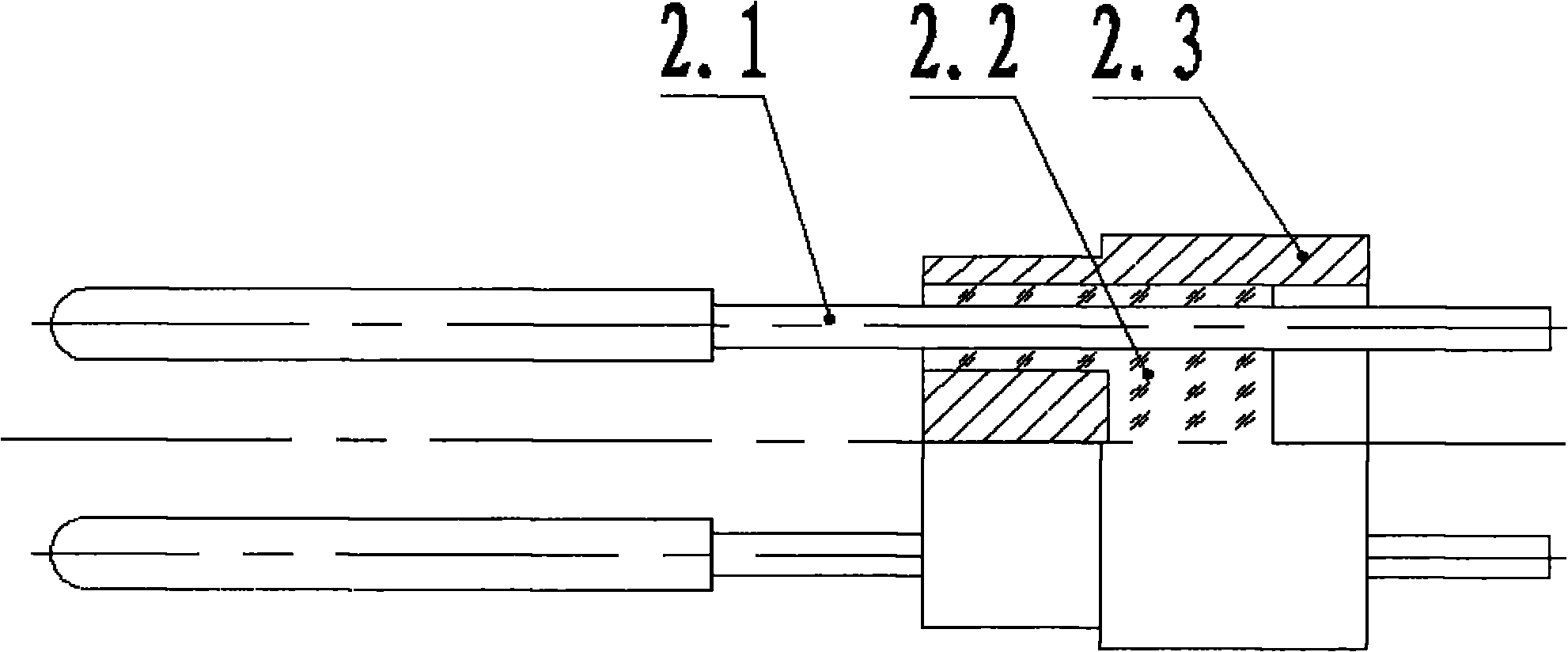

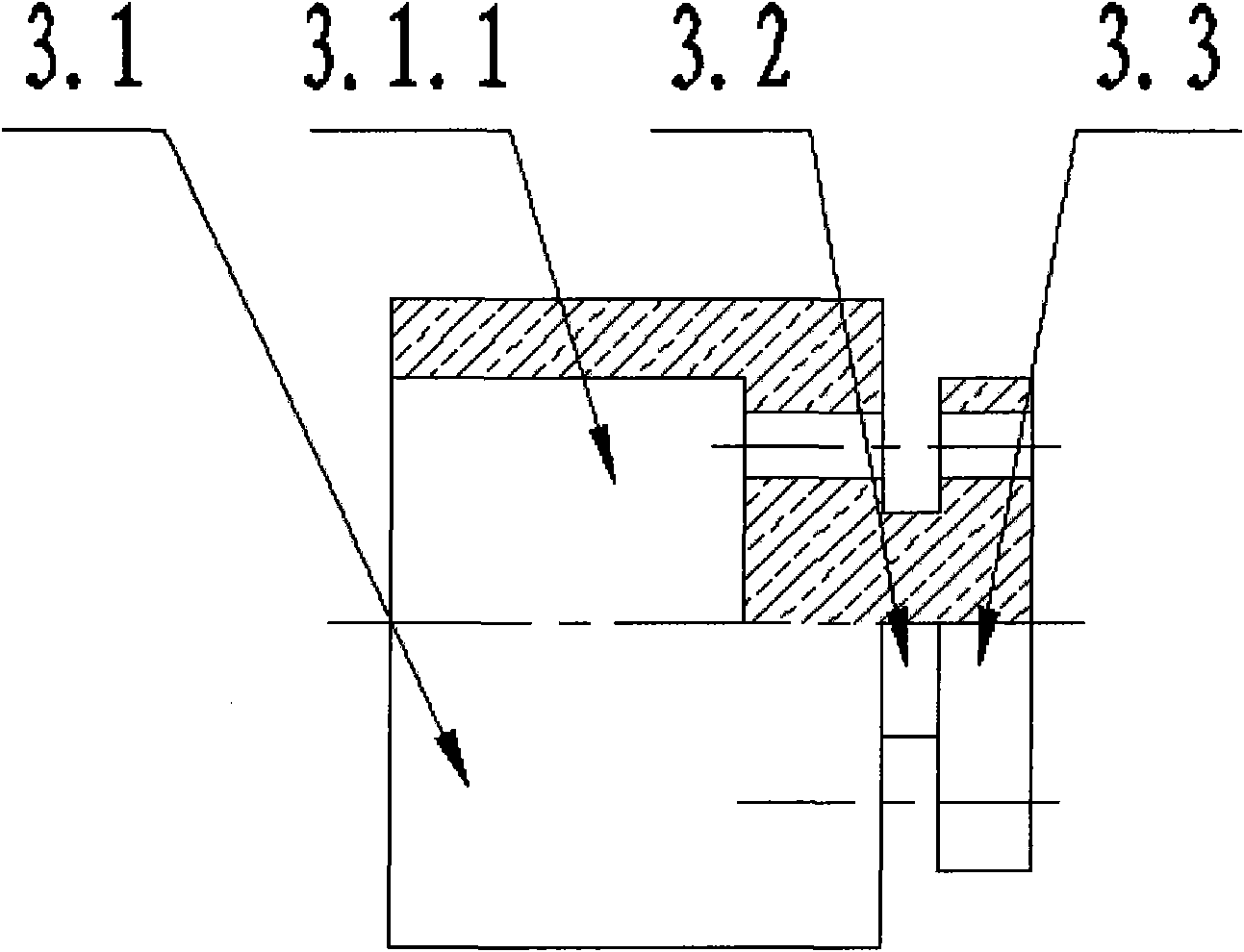

[0020] as figure 1 As shown, the electric igniter of the preferred embodiment of the present invention includes a sealant 1, an electrode plug 2, a charge cap 3, a housing 4, a bridge belt 5, a charge 6, an insulating gasket 7, a sealing cap 8 and a connector 9. Electrode plug 2 contains two electric pins 2.1, sealing glass 2.2 and electrode plug housing 2.3 (see figure 2 ), the shape of the electrode plug housing 2.3 is a convex cylinder and the inner hole has a stepped surface. Axial through holes are fixed by sealing glass and the two ends of the two electric pins 2.1 protrude from the two ends of the electrode plug housing 2.3, the sealing glass 2.2 can ensure that the present invention meets the requirements of the electric pins 2.1 and the housing 4 The insulation resistance between them is not less than 50MΩ (500V). The ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com