Catalyst of succinic acid dicarboxylic ester and preparation method thereof

A technology of succinic acid dicarboxylate and catalyst, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of easy deactivation, equipment corrosion, many side reactions, etc. Active, easy-to-operate, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

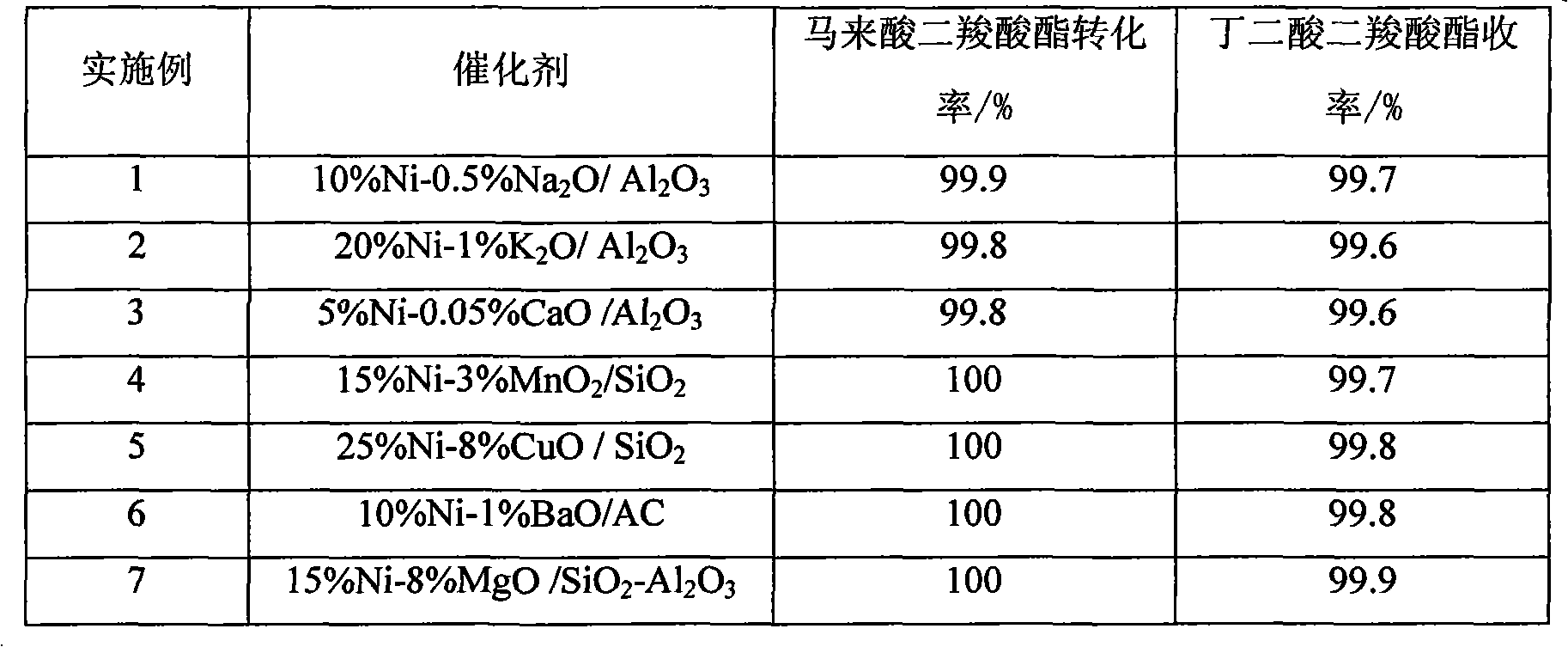

Examples

Embodiment 1

[0017] Weigh 10.0gNi(NO 3 ) 2 ·6H 2 O, 0.14gNaNO 3 Make a mixed solution with deionized water, add the prepared solution to 17.9gAl 2 o 3 The carrier is impregnated with a medium volume, dried at 100°C for 36 hours, and calcined at 450°C for 3 hours to obtain the desired catalyst. The obtained catalyst was loaded into a fixed bed reactor, and the catalyst was reduced under hydrogen at 400°C for 5h, the reaction temperature was 120°C, the pressure was 1MPa, the molar ratio of hydrogen to oil was 50, and the LHSV was 0.5h -1 , and the results are shown in Table 1.

Embodiment 2

[0019] Take 12.7gNiCl 2 ·6H 2 O, 0.21g KNO 3 Make a mixed solution with deionized water, add the prepared solution to 15.8gAl 2 o 3 The carrier is impregnated with a medium volume, dried at 150°C for 6h, and calcined at 350°C for 12h to obtain the desired catalyst. The obtained catalyst was loaded into a fixed bed reactor, and the catalyst was reduced under hydrogen at 400°C for 5h, the reaction temperature was 120°C, the pressure was 1MPa, the molar ratio of hydrogen to oil was 50, and the LHSV was 0.5h -1 , and the results are shown in Table 1.

Embodiment 3

[0021] Take 5.0gNi(NO 3 ) 2 ·6H 2 O, 0.42gCa(NO 3 ) 2 Make a mixed solution with deionized water, add the prepared solution to 19.0gAl 2 o 3 The carrier is impregnated with a medium volume, dried at 130°C for 12 hours, and calcined at 400°C for 8 hours to obtain the desired catalyst. The obtained catalyst was loaded into a fixed bed reactor, and the catalyst was reduced under hydrogen at 400°C for 5h, the reaction temperature was 120°C, the pressure was 1MPa, the molar ratio of hydrogen to oil was 50, and the LHSV was 0.5h -1 , and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com